Testing system and testing method of driver module of automobile electronic calibration software

A technology for driving modules and automotive electronics, applied in the field of automotive electronics calibration software driving module testing systems, can solve problems such as increasing system chain effects, wasting time and energy, lengthening system development cycles, and achieving the effect of improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

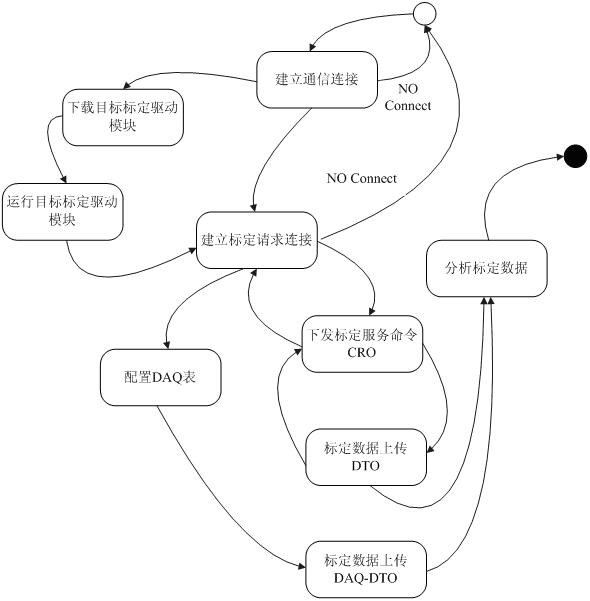

[0050] The technical solutions of the present invention will be further described in more detail in conjunction with the accompanying drawings and specific embodiments.

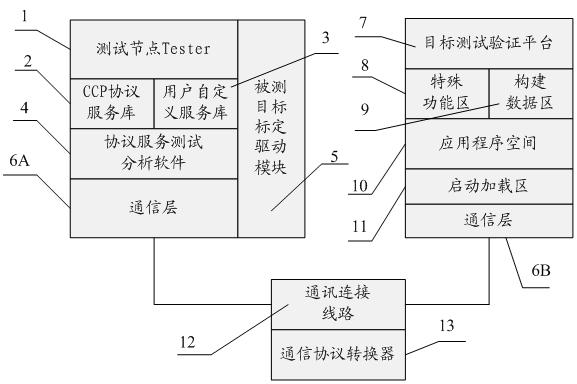

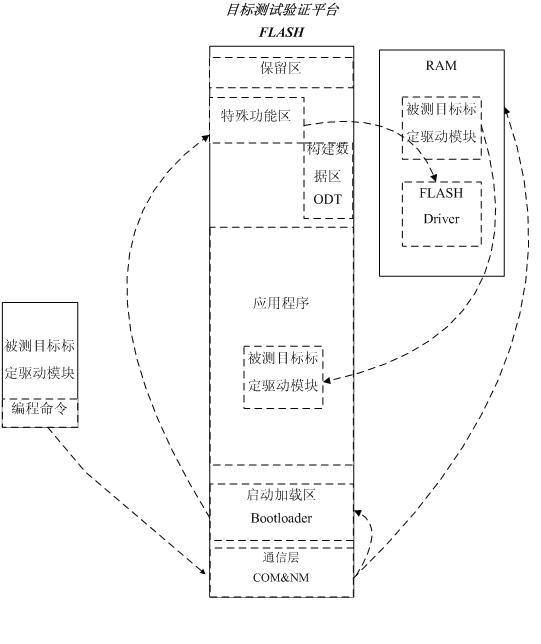

[0051] see figure 1 , an automotive electronic calibration software-driven module test system, consisting of test node Tester1, CCP protocol service library 2, user-defined service library 3, protocol service test analysis software 4, communication layers 6A, 6B, communication connection line 12, target test Verification platform 7 constitutes; Wherein

[0052] The test node Tester1 is used to run the protocol service test analysis software 4, execute the relevant commands and operations of the protocol service test analysis software 4, complete the function of the test host, realize the receiving and sending of test data and commands, provide test status display, and test The data and related analysis results are displayed; the program running on the test node Tester1 includes: CCP protocol service library ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com