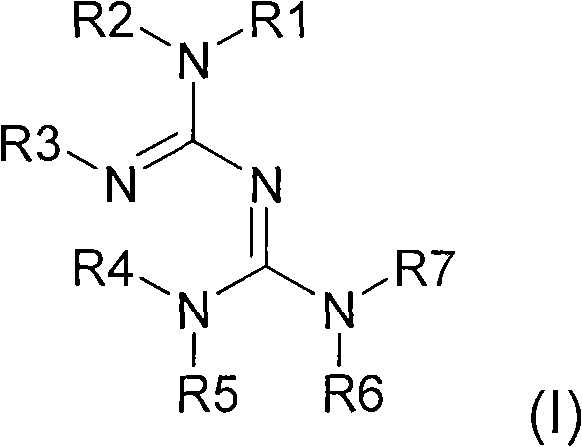

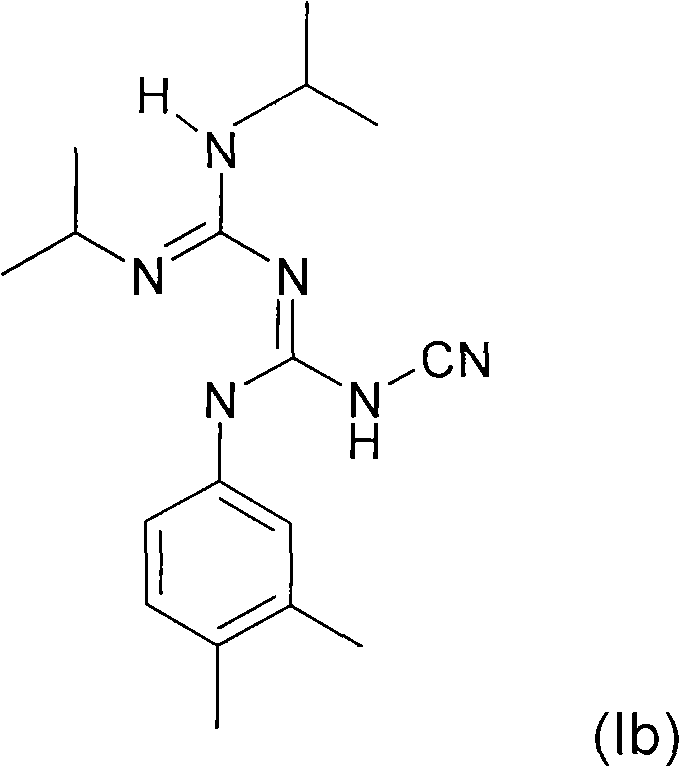

Modification of the surface chemistry of macromolecular species in the presence of a conjugated guanidine

A technology of macromolecular substances and substances, applied in the field of new macromolecular substances, can solve problems such as hindering the use, producing high, and damaging viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0267] Preparation of hyperbranched acrylic acid polymer (polymer P1)

[0268] 1.1 Synthesis of polyester polyol polymer

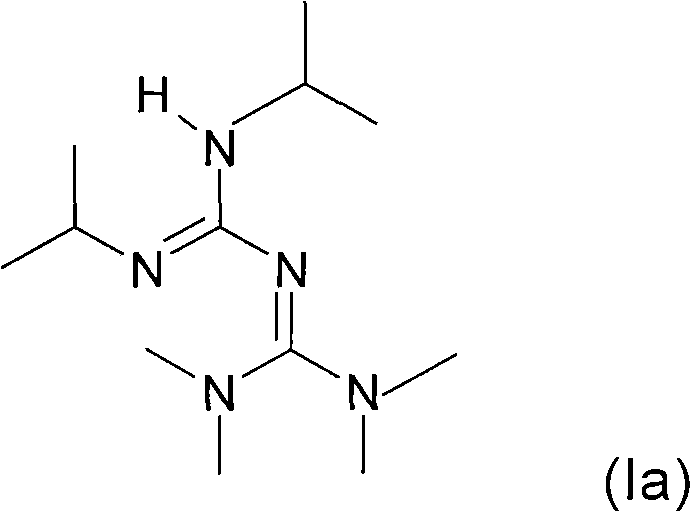

[0269] Put 126g of monomer AB2 into a 250ml jacketed reactor equipped with a mechanical stirring system and a condensation column. The medium is brought to 85° C. and 2.052 g of catalyst of formula (Ia) are added. The mixture was stirred (250 rpm) for 1 minute, then placed under -760 mmHg vacuum and stirred for 10 minutes.

[0270] 1.2 Functionalization and bridging of polyester polyol polymers (preparation of hyperbranched structures)

[0271] After 10 minutes of reaction in step 1.1, the reaction medium was brought to atmospheric pressure under nitrogen flow, the reaction temperature reached 116°C, and the temperature of the circulating fluid in the condensation column reached -20°C.

[0272] Then 51 g of MMA was gradually added to the medium. 0.820 g of catalyst of formula (Ia) and 0.380 g of BuOK (co-catalyst) were then added, using 50 mg of BH...

Embodiment 2

[0281] Synthesis of Acrylic Acrylic Hyperbranched Polymer (P2)

[0282] 2.1 Synthesis of polyester polyol polymer

[0283]Put 150g of monomer AB2 into a 250ml jacketed reactor equipped with a mechanical stirring system and a condensation column. The medium is brought to 85° C. and 2.44 g of catalyst of formula (Ia) are added. The mixture was stirred (250 rpm) for 1 minute, then placed under -760 mmHg vacuum and stirred for 10 minutes.

[0284] 2.2 Functionalization and bridging of polyester polyol polymers (preparation of hyperbranched structures)

[0285] After 10 minutes of reaction in step 1.1, the reaction medium is brought to atmospheric pressure under nitrogen flow, the reaction temperature reaches 116°C, and the temperature of the circulating fluid in the condensation column reaches -20°C.

[0286] Then 40.54 g of MMA and 12.88 g of hexanediol diacrylate (Sigma-Aldrich, Ref 411736, purity 95%) were gradually introduced into the medium. Then 0.977 g of catalyst o...

Embodiment 3

[0294] Synthesis of Hyperbranched Polymer of Acrylic Acid (Polymer P3)

[0295] 3.1 Synthesis of hyperbranched polymers with polyester polyol cores

[0296] 7.615 g of TMP (trimethylolpropane sold by Acros Organics, Ref 164650025, 98% pure) and 8.4 g of monomer AB2 were placed in a drop funnel equipped with a mechanical stirring system, condensation column and containing 117.6 g of monomer AB2 250ml jacketed reactor.

[0297] The medium was brought to 85°C and 0.137 g (Acros Organics, Ref 164650025, 98% pure) was added. The mixture was stirred (250 rpm) for 1 minute and then placed under vacuum at -760 mmHg. The mixture was subsequently stirred for 5 minutes and then placed again at atmospheric pressure.

[0298] 117.6 g of monomer AB2 contained in the dropping funnel were charged to the reactor and 1.915 g of catalyst of formula (Ia) were added again. The medium was stirred under vacuum (-760 mmHg) for 10 minutes.

[0299] 3.2 Polyester polyol bridging with diperoxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com