Swinging type screening device for screening cylindrical solid materials

A screening device and solid technology, applied in the field of swing screening devices, can solve the problems of impracticality, low efficiency, lack of separation and screening batteries, etc., and achieve high screening efficiency, solve screening problems, and facilitate installation and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

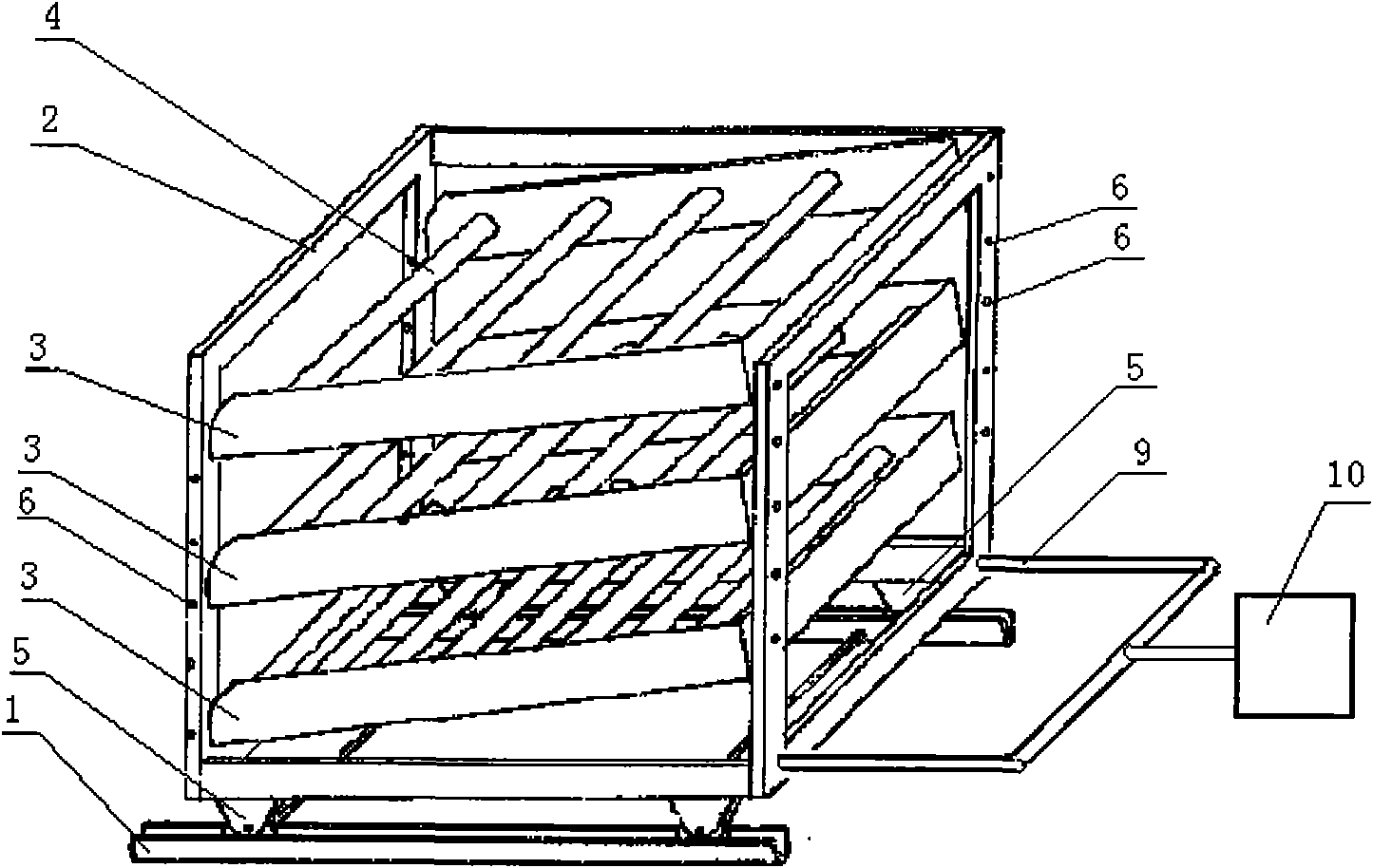

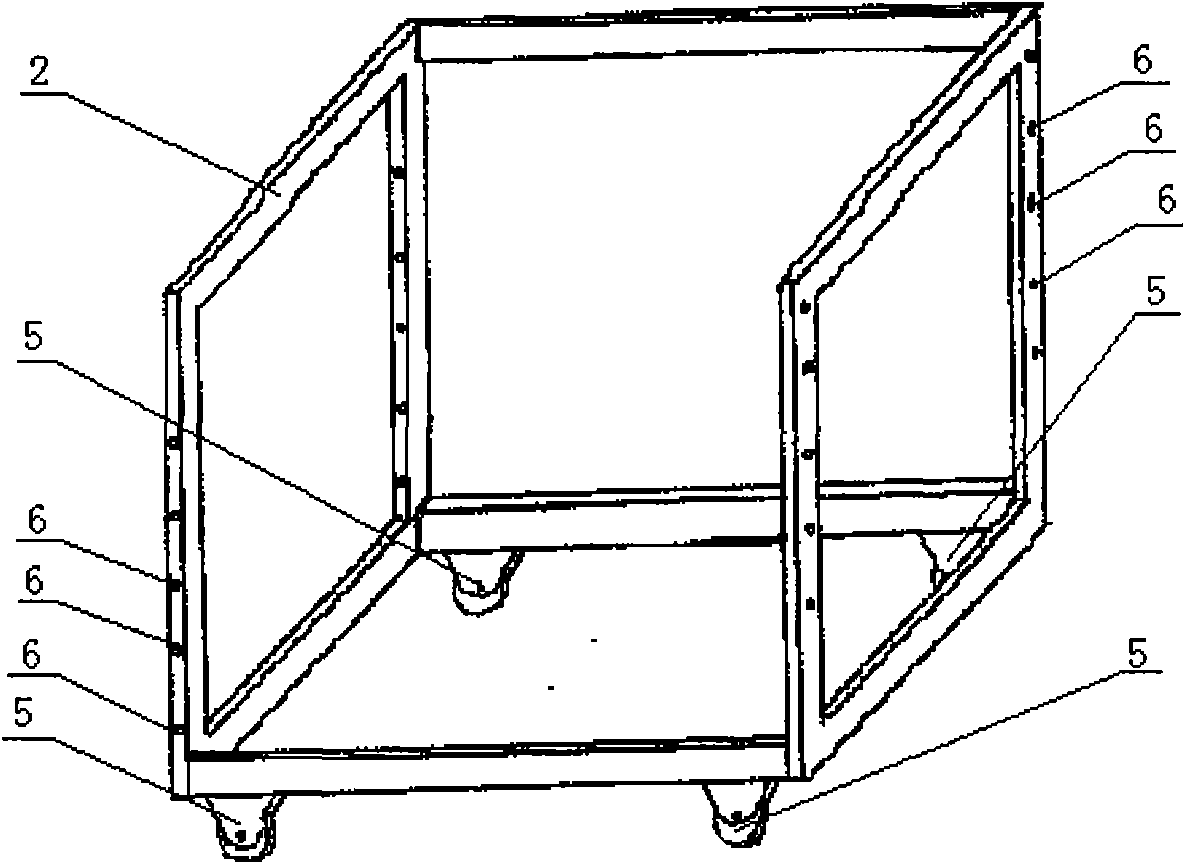

Embodiment 1

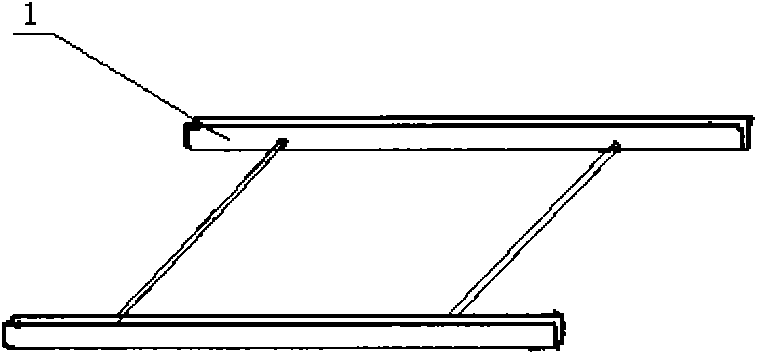

[0051]The sieve bar 4 cross-section of the rocking vibrating screening device that is used for screening solid columnar material of the present embodiment is circular surface (certainly also can be curved surface, triangular surface, quadrilateral surface, pentagonal surface, hexagonal surface) or heptagonal surface); the sieve plate 3 is three layers, and the distance between the sieve bars of the uppermost sieve plate is less than 32.3mm and greater than 25.3mm; the distance between the sieve bars of the middle sieve plate is less than 25.3mm, Greater than 14.1mm; the distance between the bars of the bottom sieve plate is 14.1mm, greater than 10.1mm;

[0052] The sieve plate 3 is placed obliquely, and its inclination angle is 5 degrees relative to the horizontal position (it can also be placed flat, that is, the sieve plate 3 is in a horizontal position); the high end of the sieve plate 3 placed obliquely is the solid columnar material inlet, and the The lower end of the sie...

Embodiment 2

[0066] The cross-section of the sieve bar 4 of the rocking vibration screening device for screening solid columnar materials in this embodiment is an arc-shaped surface;

[0067] The sieve plate 3 of the rocking vibration screening device for screening solid columnar materials in this embodiment has three layers, and the area of each layer of sieve plate is 0.0936 square meters, and the distance between the sieve bars of the top sieve plate is 29 mm. The inclination angle of the plate is 50 degrees relative to the horizontal position; the distance between the bars of the middle sieve plate is 19mm, and the inclination angle of the sieve plate is 30 degrees relative to the horizontal position; the distance between the bars of the bottom sieve plate is 13mm , the inclination angle of the sieve plate is 30 degrees relative to the horizontal position;

[0068] The high end of the obliquely placed sieve plate 3 is the solid columnar material inlet, and the low end of the obliquel...

Embodiment 3

[0074] The sieve bars 4 cross-sections of the rocking vibration screening device for screening solid columnar materials of the present embodiment are all triangular faces or quadrangular faces; each set of device sieve plates 3 has three layers, and each set of devices Adopt the sieve bar 4 of same shape;

[0075] The sieve plate 3 of the rocking vibration screening device for screening solid columnar materials in this embodiment has three layers, and the area of each layer of sieve plate is 0.0936 square meters, and the distance between the sieve bars of the uppermost sieve plate is 29mm; The distance between the sieve bars of the first sieve plate is 19mm; the distance between the sieve bars of the bottom sieve plate is 13mm, and the inclination angle of the sieve plate is 20 degrees relative to the horizontal position;

[0076] The driver 10 used in this embodiment is a linear reciprocating motor, and the driver 10 drives the rectangular frame-type main body 2 to reciproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com