Three-dimensional sandwich textile material filled by phenolic aldehyde foams

A fabric material and phenolic foam technology, applied in building construction, layered products, construction, etc., can solve the problems of unsatisfactory impact resistance, complicated construction procedures, long construction period, etc., and achieve light weight and increased compressive strength. The effect of large, transverse shear force increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

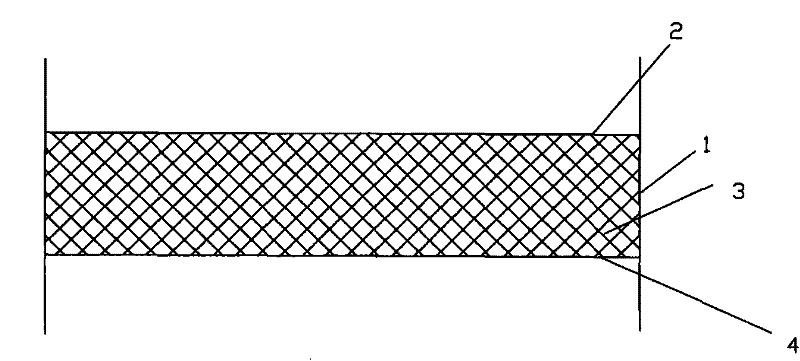

[0017] Such as figure 1 As shown, a three-dimensional sandwich fabric material filled with phenolic foam comprises an upper fabric surface, an intermediate core structure and a lower fabric surface, the intermediate core structure uses the three-dimensional sandwich fabric material as a support body, and the phenolic foam is a filling matrix , the three-dimensional sandwich fabric material is one of glass fiber three-dimensional sandwich fabric, carbon fiber three-dimensional sandwich fabric or aramid fiber three-dimensional sandwich fabric. The middle core material connects the upper fabric surface and the lower fabric surface, the upper fabric surface is a planar structure, the lower fabric surface is a planar structure, and the thickness of the three-dimensional sandwich layer filled with phenolic foam is 5 ~50mm.

Embodiment 2

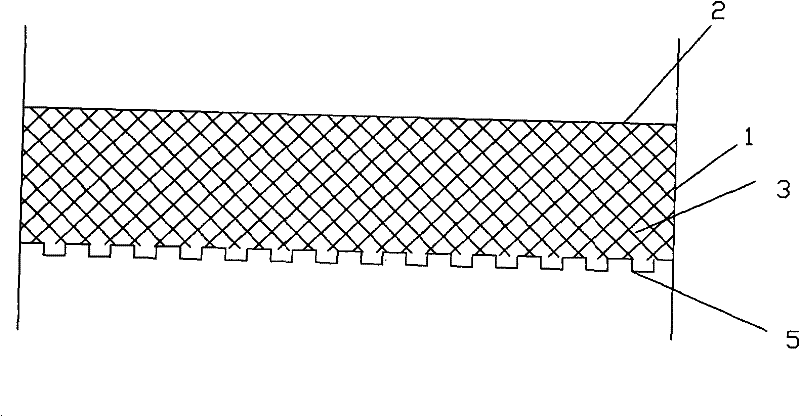

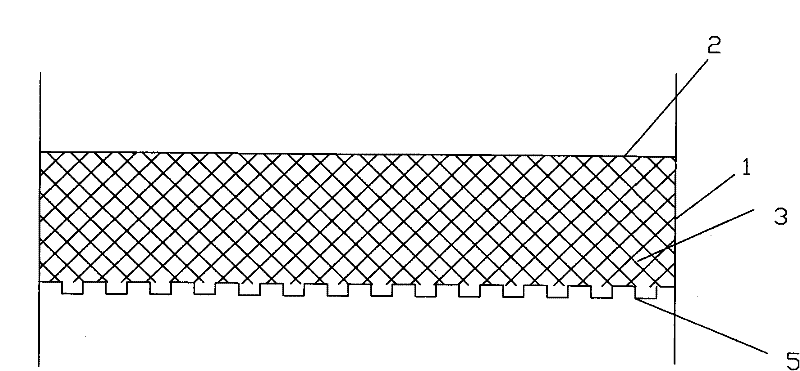

[0019] Such as figure 2 As shown, a three-dimensional sandwich fabric material filled with phenolic foam includes an upper fabric surface, an intermediate core structure and a lower fabric surface, the intermediate core structure uses the three-dimensional sandwich fabric material as a support body, and the phenolic foam is a filling matrix , the three-dimensional sandwich fabric material is one of glass fiber three-dimensional sandwich fabric, carbon fiber three-dimensional sandwich fabric or aramid fiber three-dimensional sandwich fabric. The middle core material connects the upper fabric surface and the lower fabric surface, the upper fabric surface is a planar structure, the thickness of the three-dimensional sandwich layer filled with phenolic foam is 5-50 mm, and the lower fabric surface is Concave-convex surface structure, the height of the convex surface is 0.5-20mm, and the width of the concave surface is 10-600mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com