Formation of microstructured fiber preforms using porous glass deposition

An optical fiber preform and microstructure technology, applied in glass fiber products, glass manufacturing equipment, applications, etc., can solve the problems of uncontrollable position and size, easy to change and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

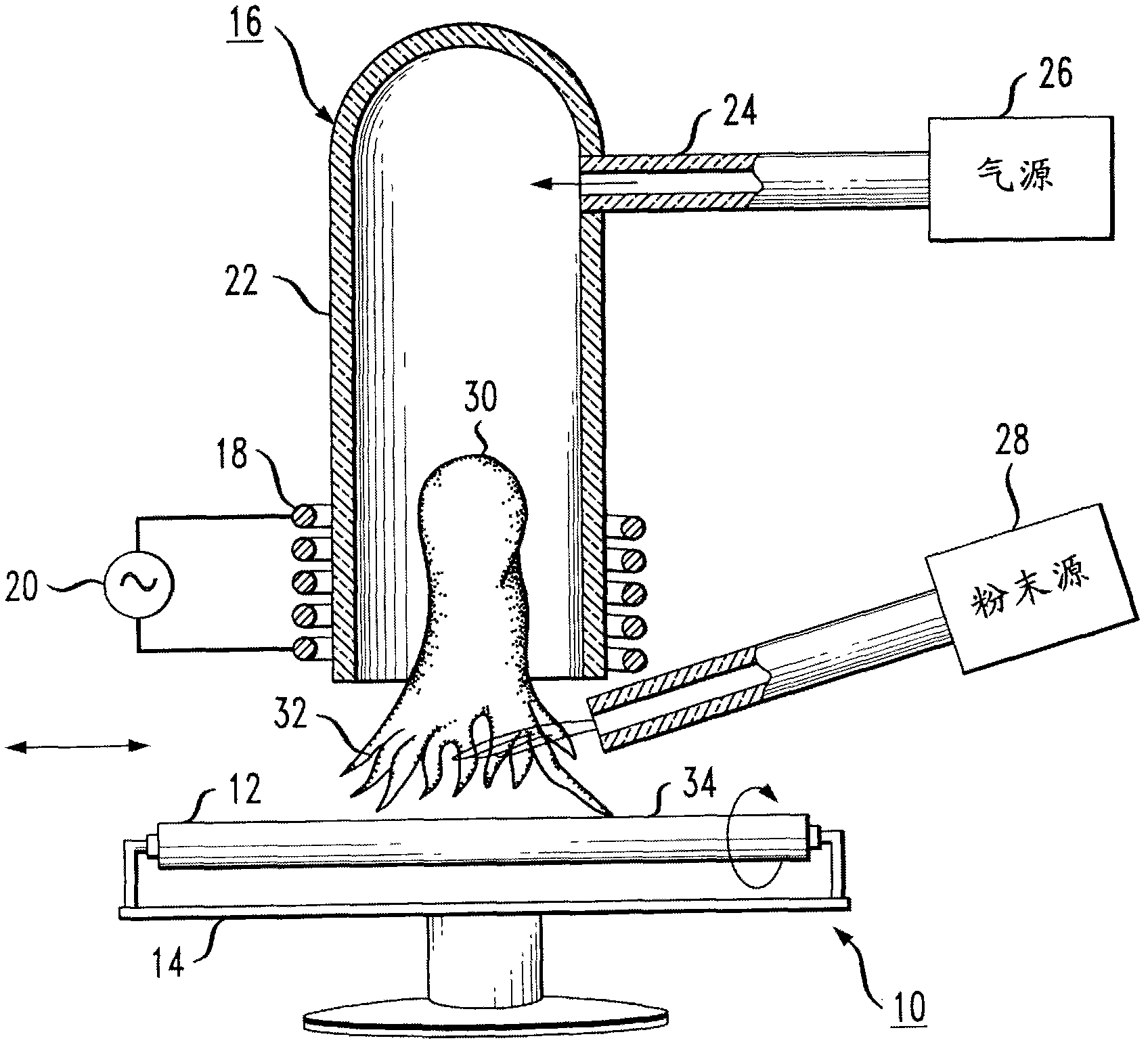

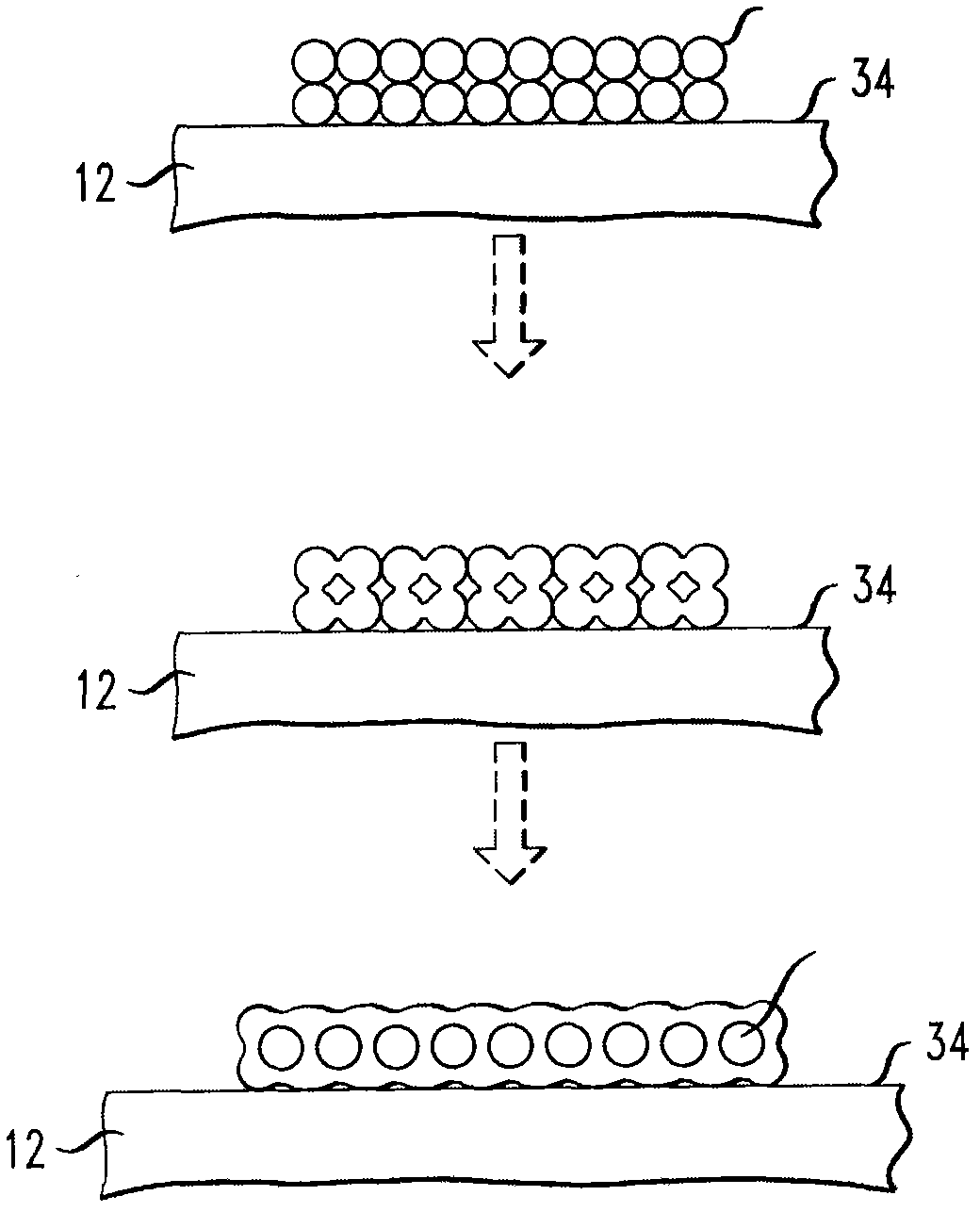

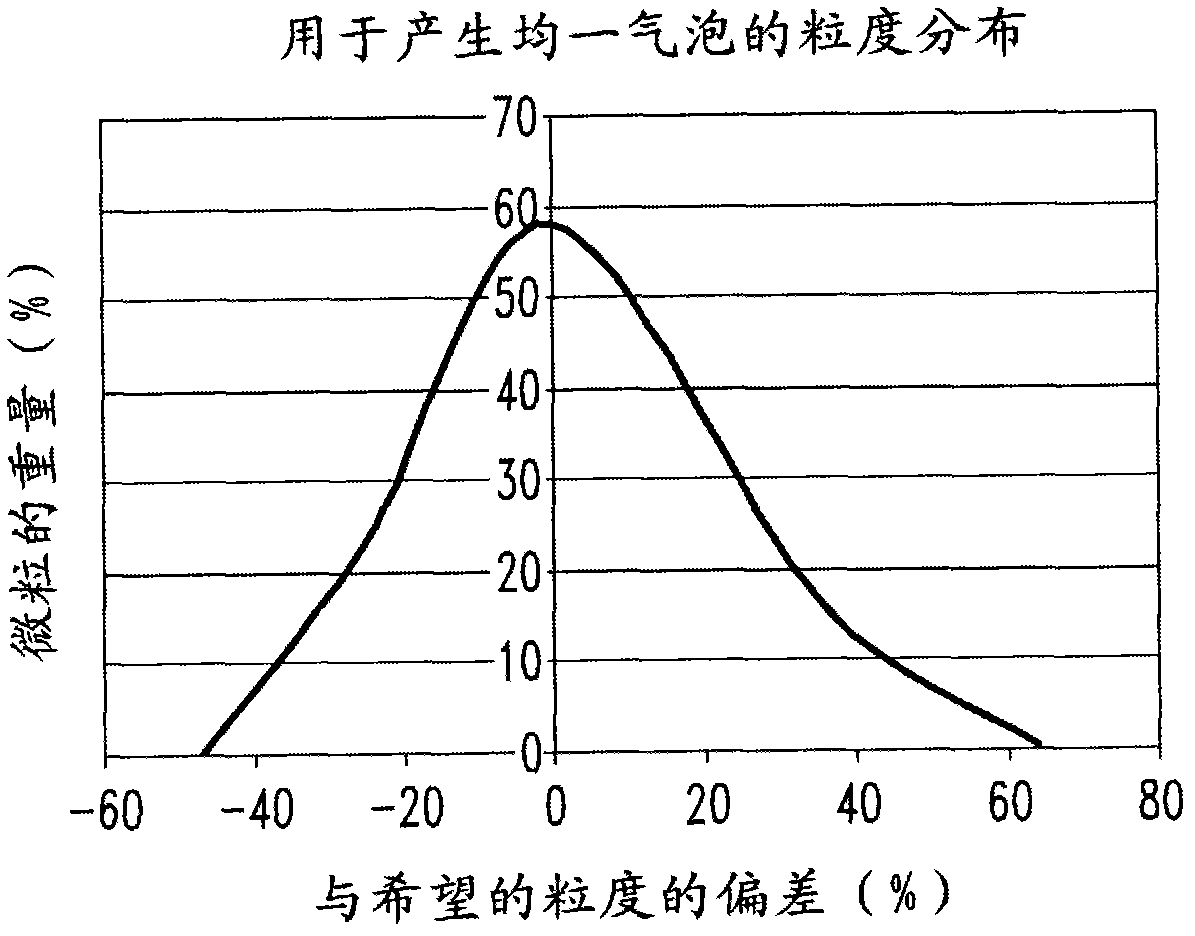

[0018] It has been found that a porous material can be deposited onto an optical fiber preform substrate to form gas bubbles that are part of the preform structure. By incorporating gas bubbles into a layer of the preform structure (e.g., as an annular layer in the cladding structure), the effective refractive index of that layer can be easily changed, which is the key to controlling the refractive index profile of optical fibers drawn from the preform. useful tool. According to the invention, a powder with particles of controlled size, such as silicon oxide powder, is deposited on the outer surface of the preform substrate by means of a plasma process. The desired size and density of the bubbles are effectively controlled by selecting appropriate deposition conditions such as but not limited to: (1) rotation of the preform substrate relative to the plasma source and translational motion; (2) maintain the temperature at a value near the fiber drawing temperature; and (3) the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com