Preparation method of high-viscosity-index lubricating oil base oil

A lubricating oil base oil, high viscosity technology, applied in lubricating compositions, base materials, processing hydrocarbon oils, etc., can solve the problems of low lubricating oil yield, large loss of product viscosity, difficulty and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

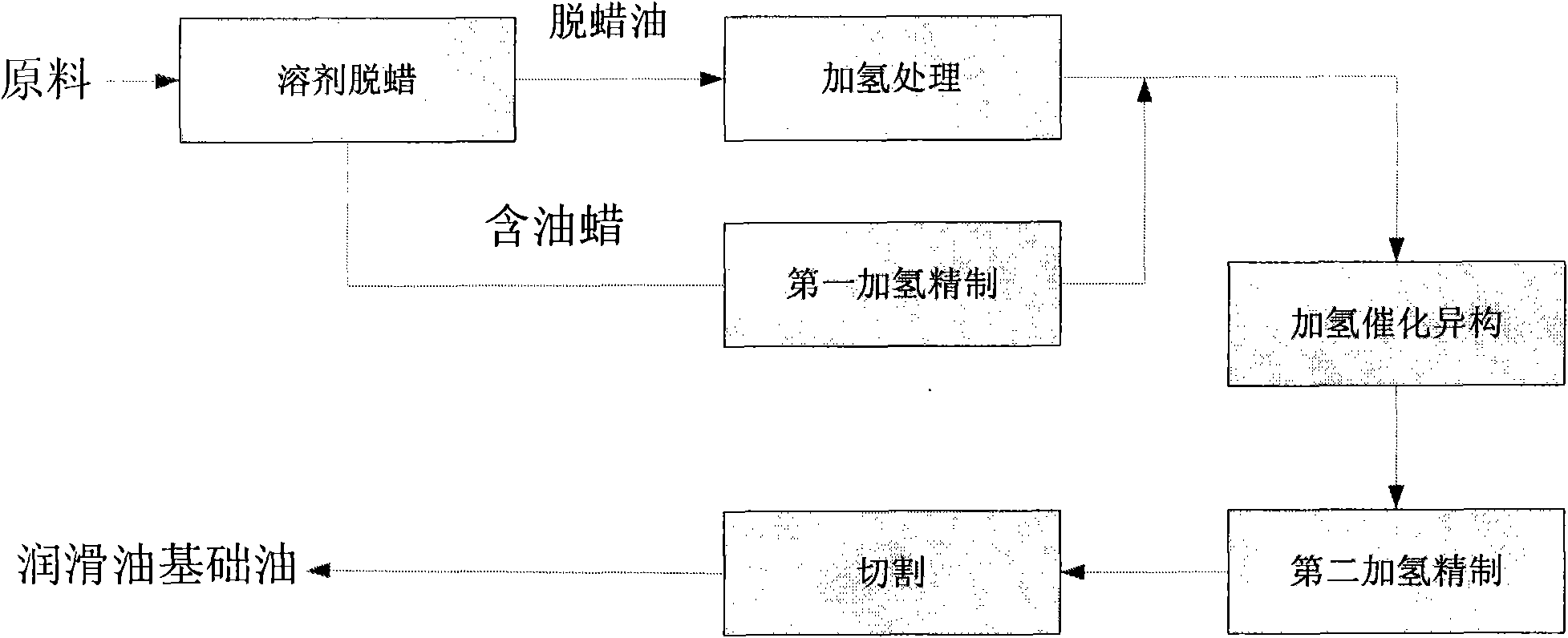

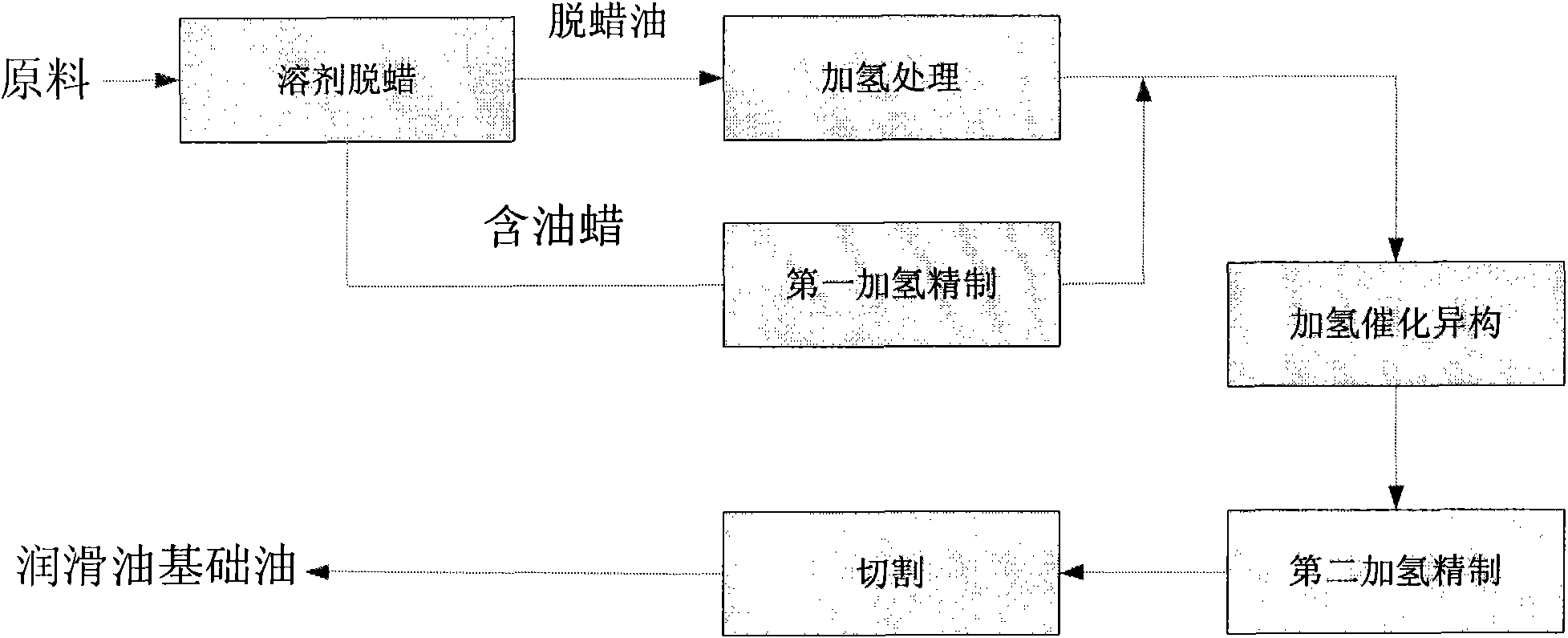

[0022] Such as figure 1 Shown, the preparation method of lubricating base oil provided by the invention may further comprise the steps:

[0023] (1) The raw material is contacted with a dewaxing solvent to remove the wax in the waxy oil to obtain dewaxed oil and oily wax. The conditions of contact are such that the freezing point of the obtained dewaxed oil is -30°C to 5°C. The raw material are vacuum distillates and / or lightly deasphalted oils;

[0024] (2) contacting the above-mentioned dewaxed oil with a hydroprocessing catalyst in the presence of hydrogen to obtain a hydroprocessing product with a sulfur content reduced to not higher than 10 ppm and a nitrogen content reduced to not higher than 2 ppm;

[0025] (3) contacting the oil-containing wax obtained in step (1) with the first hydrorefining catalyst in the presence of hydrogen to obtain the first hydrorefining product whose sulfur content is reduced to not higher than 10 ppm and nitrogen content is reduced to not hi...

Embodiment 1

[0049] This embodiment is used to illustrate the preparation method of the lubricating oil base oil provided by the present invention.

[0050] according to figure 1 The described procedure prepares lube base oils.

[0051](1) With the refinery vacuum distillate oil 1 as raw material (the properties of the vacuum distillate oil 1 are shown in Table 1 below), the above-mentioned raw material is contacted with a dewaxing solvent to remove wax in the waxy oil, and the yields are respectively 70% by weight dewaxed oil and 30% by weight oily wax. Used dewaxing solvent is the mixture of methyl ethyl ketone and toluene, and its volume ratio is 65 / 35, and dewaxing condition is the weight ratio of dewaxing solvent and stock oil 4.4: 1, and cold spot raw material temperature is 36 ℃, and cold spot solvent temperature 32°C, the final cooling temperature and filtration temperature are both 10°C. The properties of the obtained dewaxed oil are shown in Table 2 below.

[0052] (2) The de...

Embodiment 2-3

[0057] This embodiment is used to illustrate the preparation method of the lubricating oil base oil provided by the present invention.

[0058] Prepare lubricating oil base oil according to the method of Example 1, the difference is, the property of raw material oil, the property of dewaxed oil, the condition of hydroprocessing, the property of hydroprocessing product, the property of dewaxed oil and oily wax mixture, The conditions of the first hydrorefining, the properties of the first hydrorefining products, the conditions of hydrocatalytic isomerization / second hydrorefining, and the properties of the second hydrorefining products are respectively shown in Table 1-9 below. The properties of the oil products are shown in Table 10 below. The yields of the lubricating base oil products relative to the raw materials used in step (1) were 68% by weight and 65% by weight, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com