Spiral casing of low-vibration and low-noise centrifugal pump

A low-noise and low-vibration technology, applied in the field of centrifugal pumps, achieves the effects of simple structure, alleviating strong pressure pulsation, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

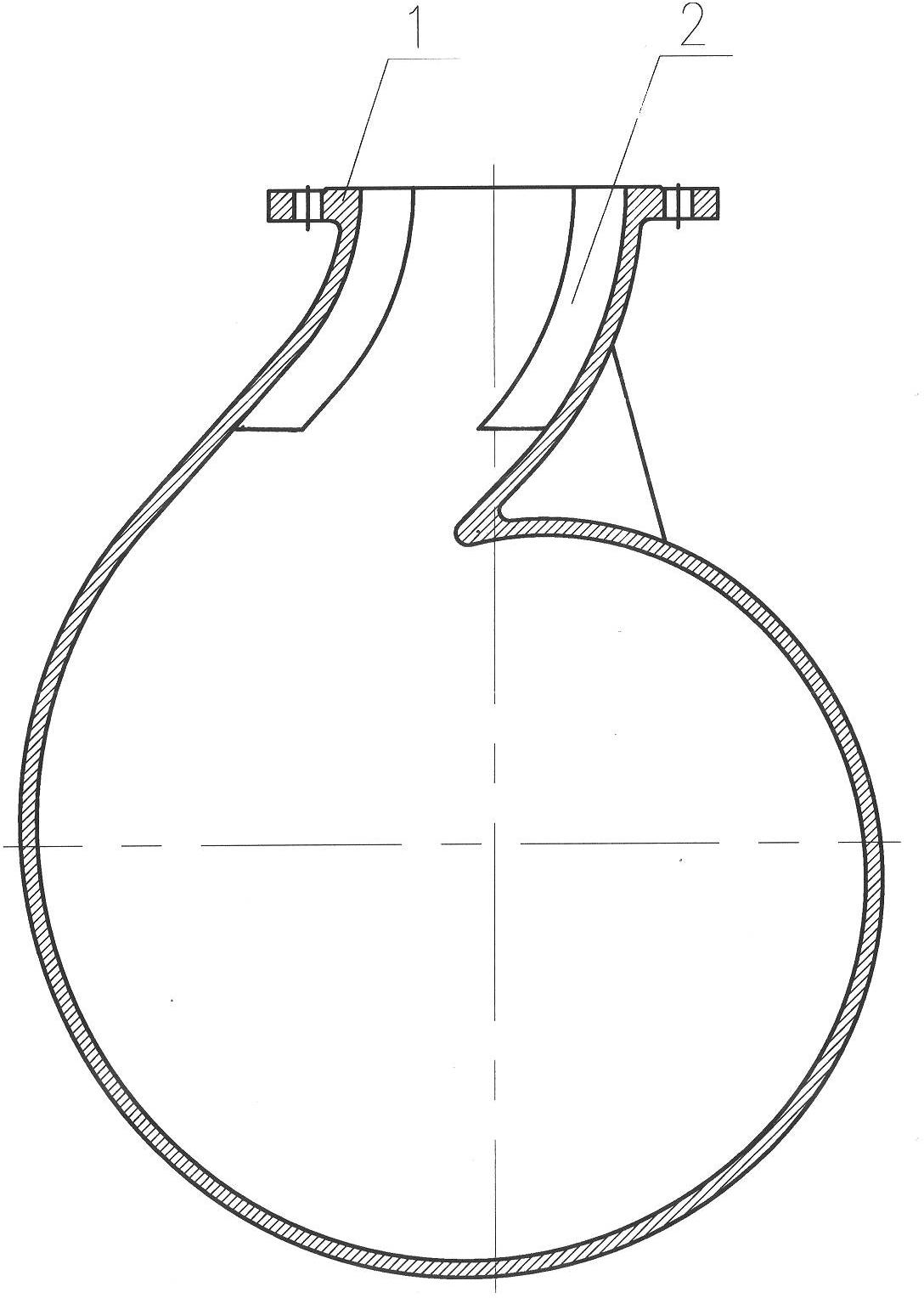

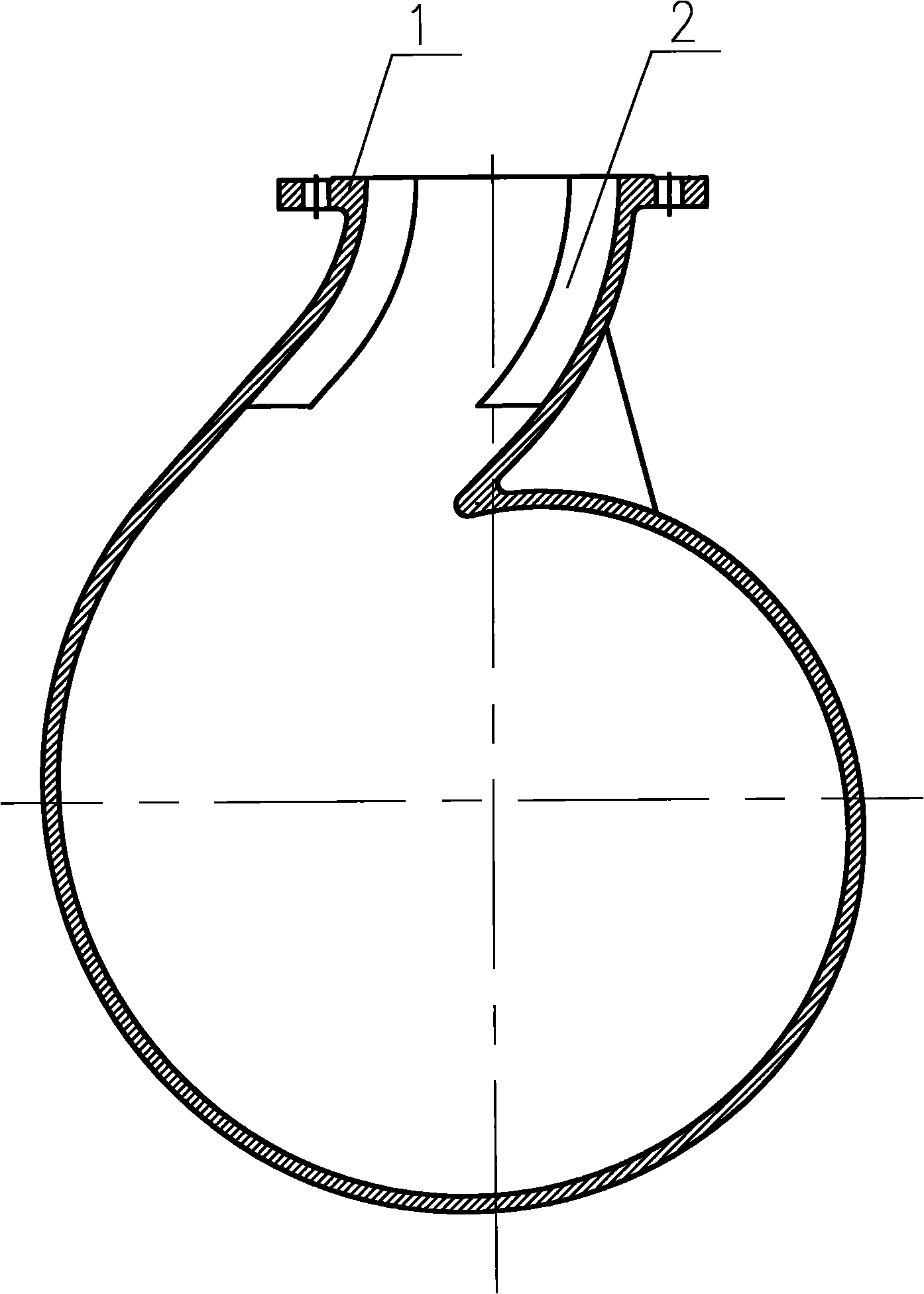

[0014] combine figure 1 , the low-vibration and low-noise centrifugal pump volute of the present invention includes components such as a casing 1 and a guide vane 2, and the guide vane 2 is fixed on the casing 1 by welding to improve the flow state in the diffusion section of the casing to achieve Mitigates the effect of unsteady flow-induced vibrational noise.

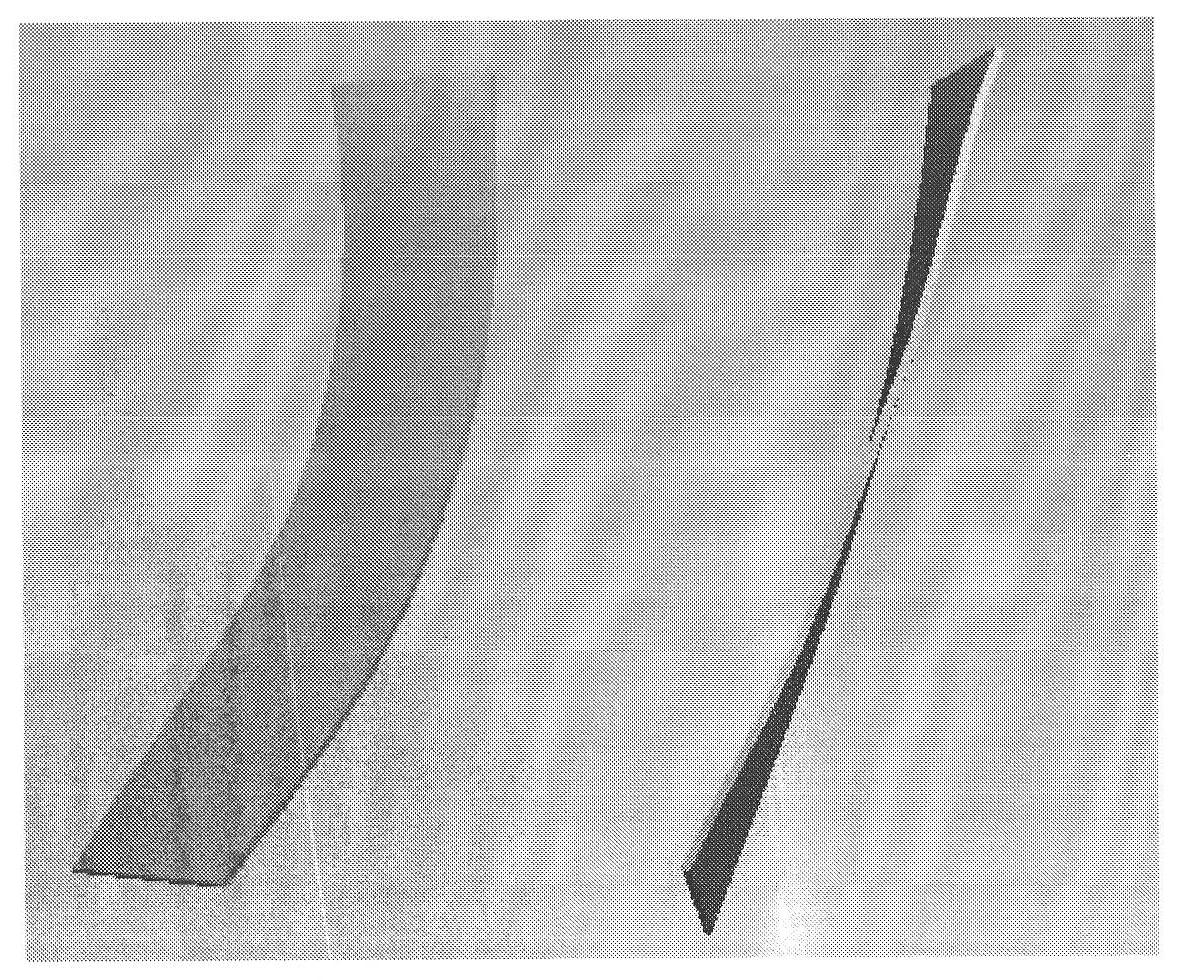

[0015] combine figure 2 , The embodiment guide vane 2 is a three-dimensional twisted type, the number of blades is 2, the thickness is 3mm, and it is processed by impact molding. The guide vane inlet placement angle is 28°, and the outlet placement angle is 0°.

[0016] The working process is as follows:

[0017] The casing 1 is a pressurized water chamber used to collect the liquid at the outlet of the impeller of the centrifugal pump, which converts the kinetic energy of the liquid into pressure energy. The casing is fixed, and the static and dynamic interference between the rotation of the impeller of the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com