Method for quickly measuring viscous flow activation energy of polyolefin

A technology of polyolefin and activation energy, which is applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problems of low efficiency and low measurement efficiency, and achieve the effect of easy operation and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Viscous flow activation energy of HDPE 9455F.

[0070] Table 1 Viscous flow activation energy of HDPE 9455F

[0071]

Embodiment 2

[0077] Viscous flow activation energy of LDPE 2426H.

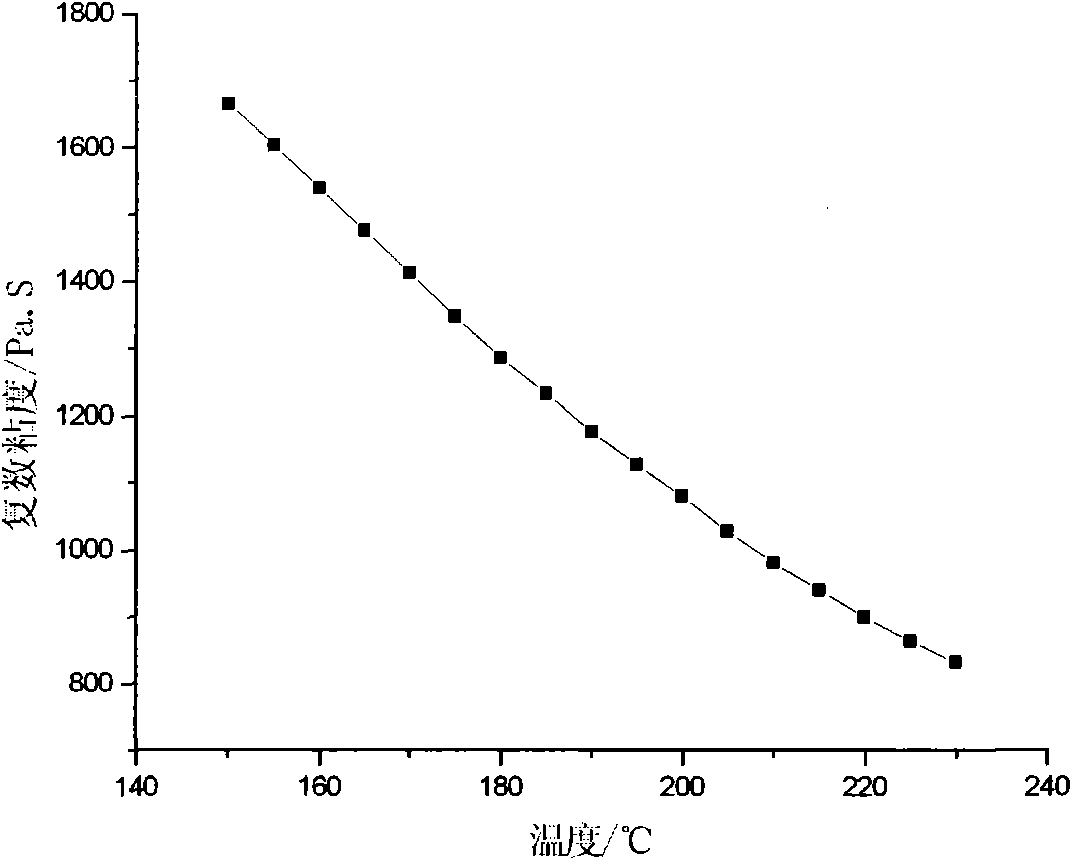

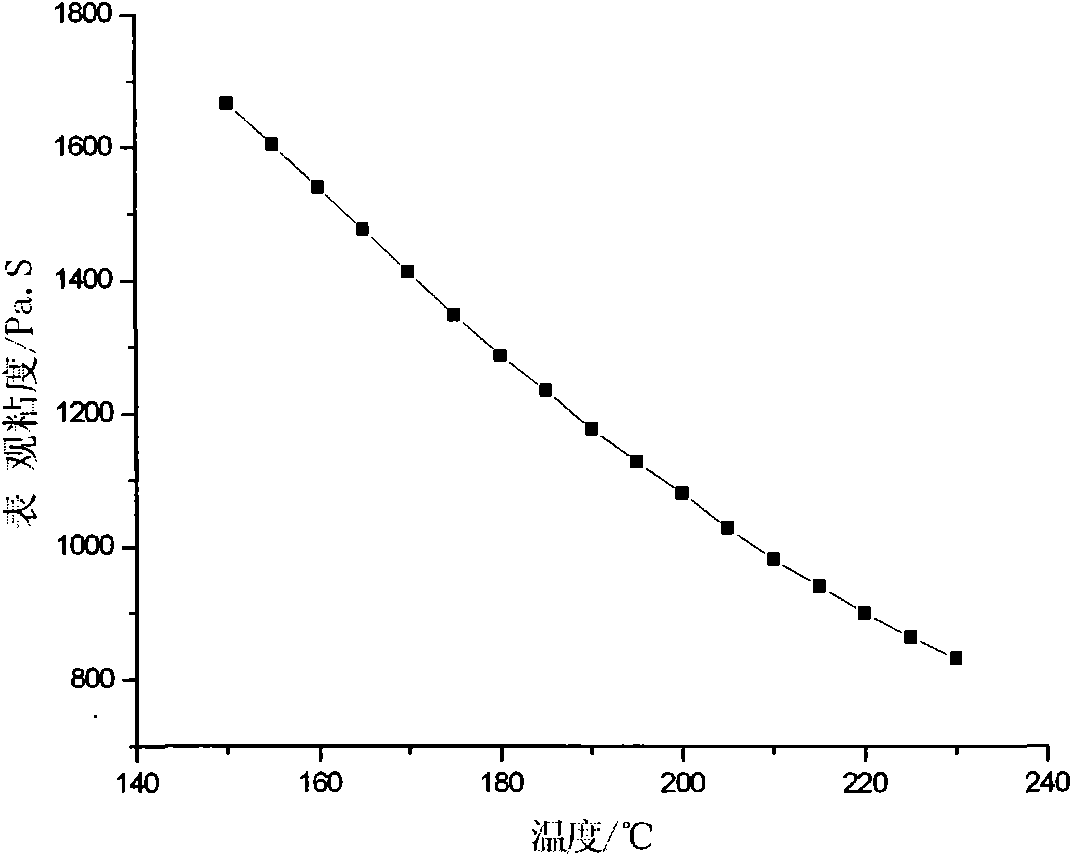

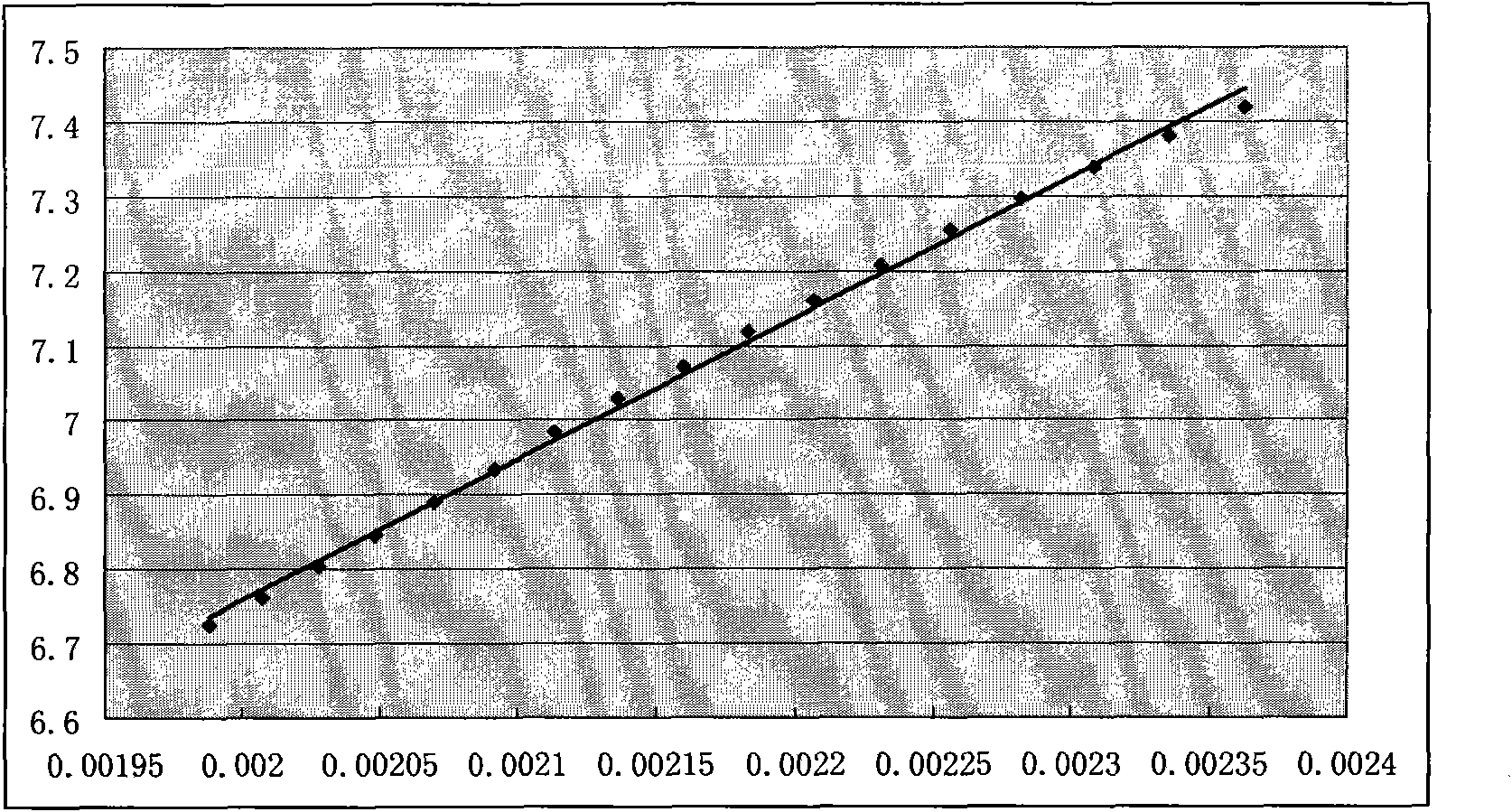

[0078] figure 1 It is the rheological test curve of LDPE 2426H, and the corresponding complex viscosity values at 17 temperatures can be obtained through a temperature scanning measurement; figure 2 It is the curve of LDPE 2426H converted by the Cox-Merz rule, and the apparent viscosity values at 17 temperatures are obtained after data conversion; image 3 The curve obtained for LDPE 2426H linear regression, that is, the apparent viscosity value at each temperature is linearly regressed to the corresponding temperature in Microsoft Excel software, and the parameters in the regression formula are obtained, and the activation energy of viscous flow is calculated, as shown in the table 3.

[0079] Table 3 Viscous flow activation energy of LDPE 2426H

[0080]

Embodiment 3

[0082] Viscous flow activation energy of LLDPE LL1201.

[0083] Viscous flow activation energy of table 4LLDPE LL1201

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com