High-temperature high-pressure multifunctional core sulfur deposition test device and method

A high temperature and high pressure, testing device technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve sulfur plugging, can not accurately and dynamically evaluate the permeability damage of reservoir rock samples caused by sulfur deposition in real time degree, production cannot be carried out normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

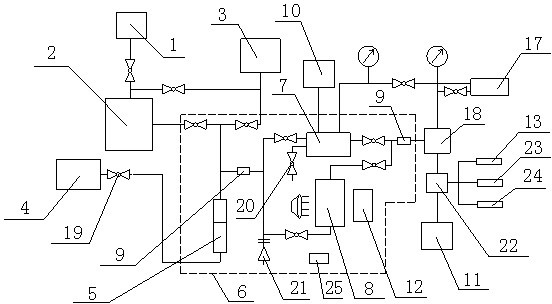

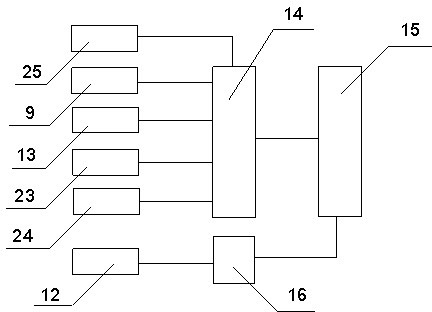

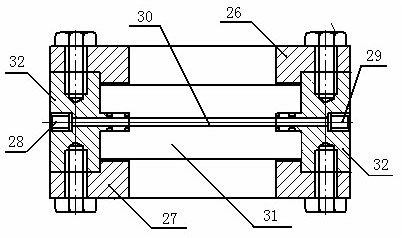

[0078] Further describe the technical scheme of the present invention below in conjunction with accompanying drawing: as figure 1 A high-temperature and high-pressure multifunctional rock core sulfur deposition testing device includes a displacement system, a formation condition simulation system, a data acquisition system and a data processing system.

[0079] The displacement system includes a sampler 1, a sampler 2, a gas booster pump 3, a constant speed and constant pressure pump 4, an intermediate container 5, a hand pump 17 and a back pressure valve 18, and the sampling port of the sampler 1 passes through The pipeline is connected to the sample inlet of the sampler 2, and the interface of the gas booster pump 3 is connected to the interface of the sampler 2 through the pipeline; the outlet of the constant speed and constant pressure pump 4 is connected to the lower inlet of the intermediate container 5 through the pipeline , the interface of the gas booster pump is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com