Large joint surface experiment device

An experimental device and joint surface technology, which is applied in the field of large joint surface normal stiffness and tangential stiffness detection devices, and can solve problems such as limiting the use range of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

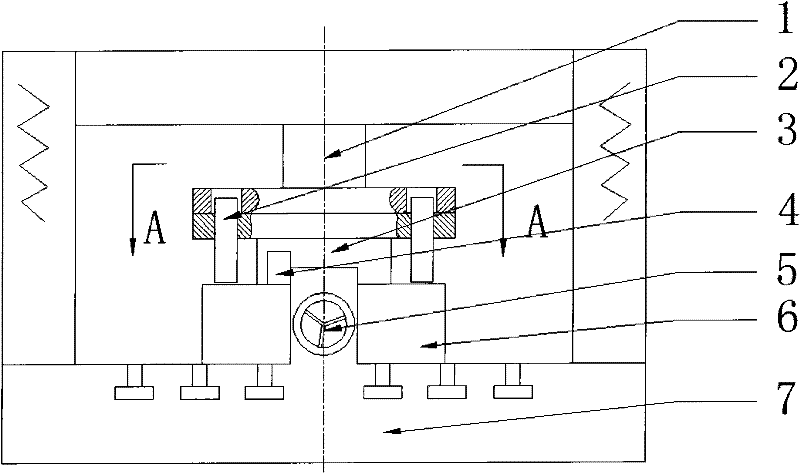

[0037] An embodiment of the present invention will be specifically described below in conjunction with the accompanying drawings.

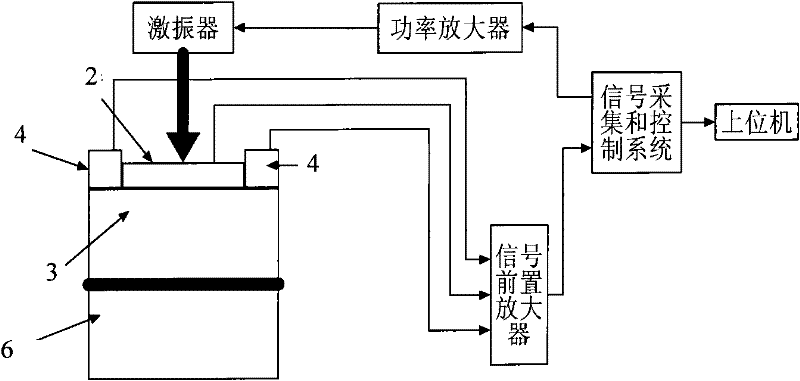

[0038] refer to image 3As shown, the large joint surface experimental device of this embodiment is mainly composed of a normal force applying device 1, a normal eddy current sensor 2, an upper specimen 3, an acceleration sensor 4, a tangential force applying device 5, a lower A test piece 6, a workbench 7, a tangential eddy sensor 8, and a tangential force sensor are composed 9. The workbench 7 is arranged on the lower part of the mechanical frame, and the table top of the workbench 7 is a working surface provided with a uniform T-shaped groove; the lower test piece 6 is a square cylinder, and the lower test piece 6 is placed on the workbench 7. The bottom surface of piece 6 is provided with a positioning boss, and the positioning boss is embedded in the T-shaped groove of workbench 7; A screw-type manual pre-adjuster is provided. By adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com