Colloidal crystal-modified optical fiber microstructural device and manufacturing method thereof

A colloidal crystal and microstructure technology, applied in cladding optical fibers, optical waveguides and light guides, etc., can solve the problem of high production cost, and achieve the effect of narrow frequency band and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

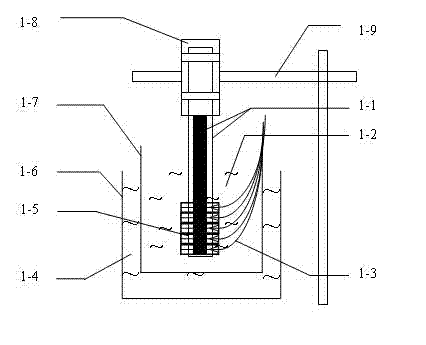

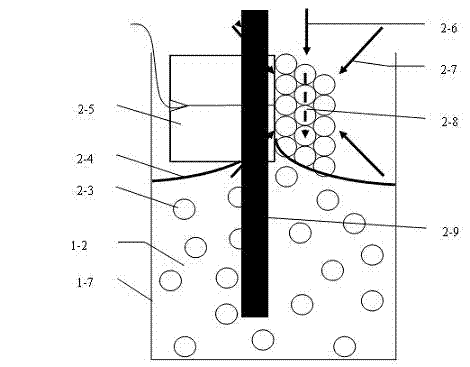

[0020] Further detailed description will be given below in conjunction with the accompanying drawings and embodiments.

[0021] The steps of preparing optical fiber microstructure device in this embodiment are as follows:

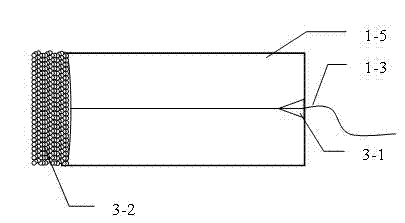

[0022] a) Cut a piece of ordinary single-mode fiber 1-3, with a core of 9 μm and a cladding of 125 μm. After peeling off a 6 mm long section of the coating layer at one end of the fiber 1-3 with pliers, apply a layer of optical fiber glue on the bare fiber, and insert Among the capillary tubes 1-5 with a bell mouth 3-1 at one end, the capillary tube 1-5 is 9 mm long, with an inner diameter of 0.126 mm and an outer diameter of 1.8 mm. The horn mouth 3-1 clamps the coating at the other end of the optical fiber 1-3, Fill the bell mouth 3-1 with glue to fix the optical fiber 1-3 to form an optical fiber-capillary structure 2-5 with an optical fiber pigtail at one end. Grind to smooth on the same plane of 90 degrees radial direction of optical fiber 1-3;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com