Method and equipment for processing PCB (Printed Circuit Board)

A PCB board and processing method technology, applied in the field of printed circuit board processing, can solve the problems of poor drilling hole position accuracy, poor positioning accuracy, low processing efficiency, etc., to achieve convenient machining, reduce burrs and drilling pollution, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

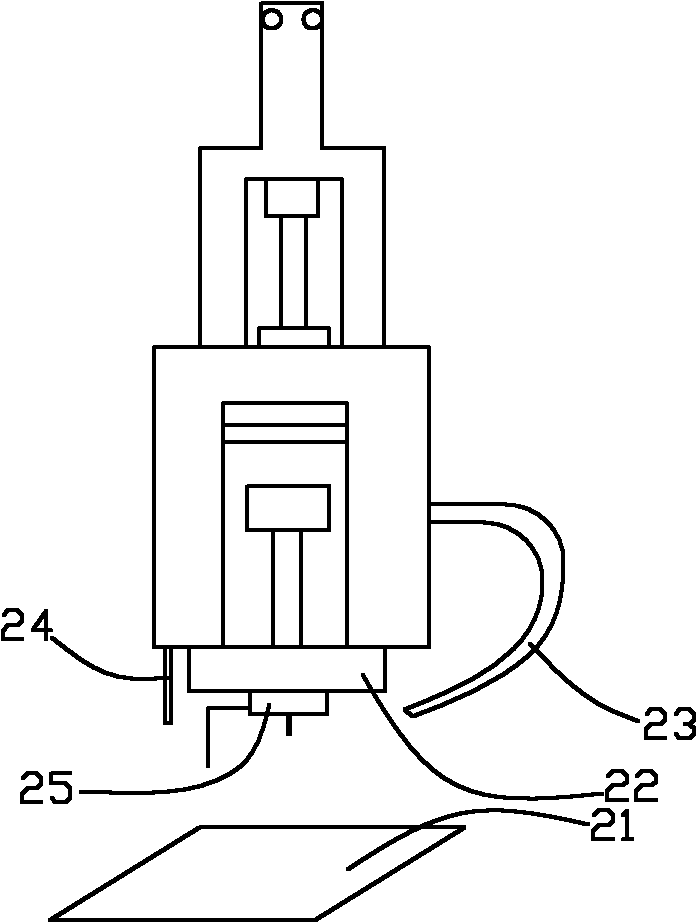

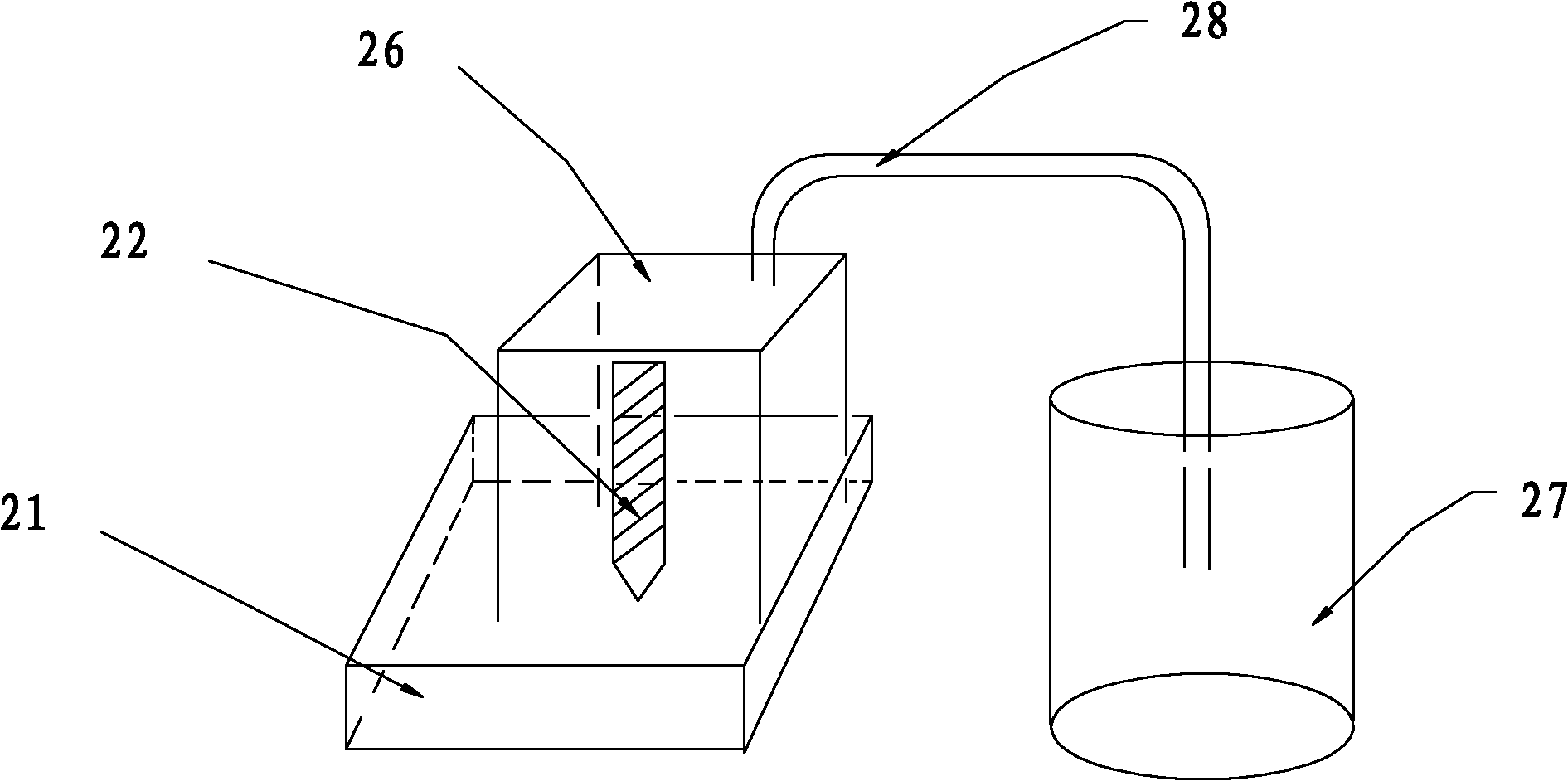

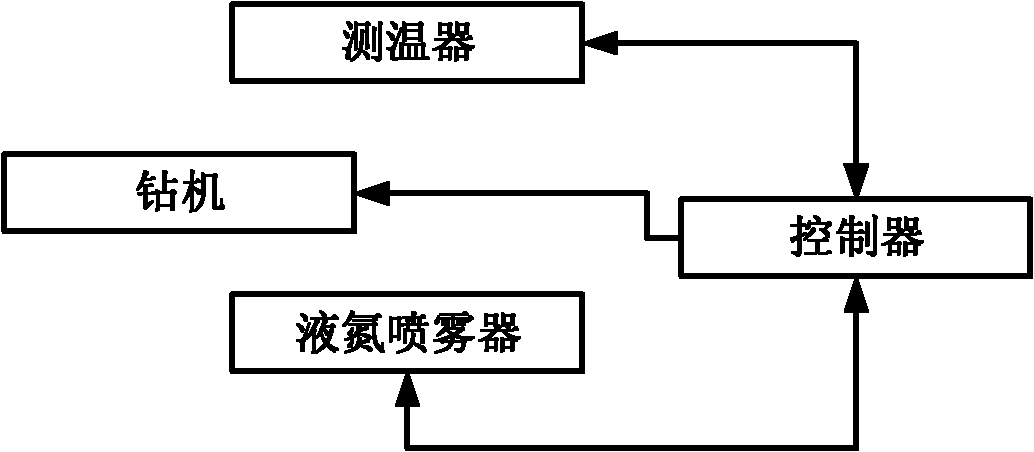

[0028] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

[0029] As an embodiment of the PCB board processing method of the present invention, during the mechanical processing of the PCB board, the temperature of the PCB board to be processed is always controlled below the glass transition temperature by using a cooling liquid or a cooling solid. Taking the PCB material as PTFE material as an example, the temperature of the PCB board to be processed is always controlled below 25°C.

[0030] The PCB board processing method of the present invention uses coolant or cooling solid to directly cool the PCB board to be processed at the processing site, and the temperature of the PCB board to be processed is always controlled below the glass transition temperature. Hard and brittle, convenient for mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com