Method for applying a pressure sensitive shrink label to an article

A label and product technology, applied in the field of pressure-sensitive shrink labels, can solve the problems of high cost, excessive waste, label defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

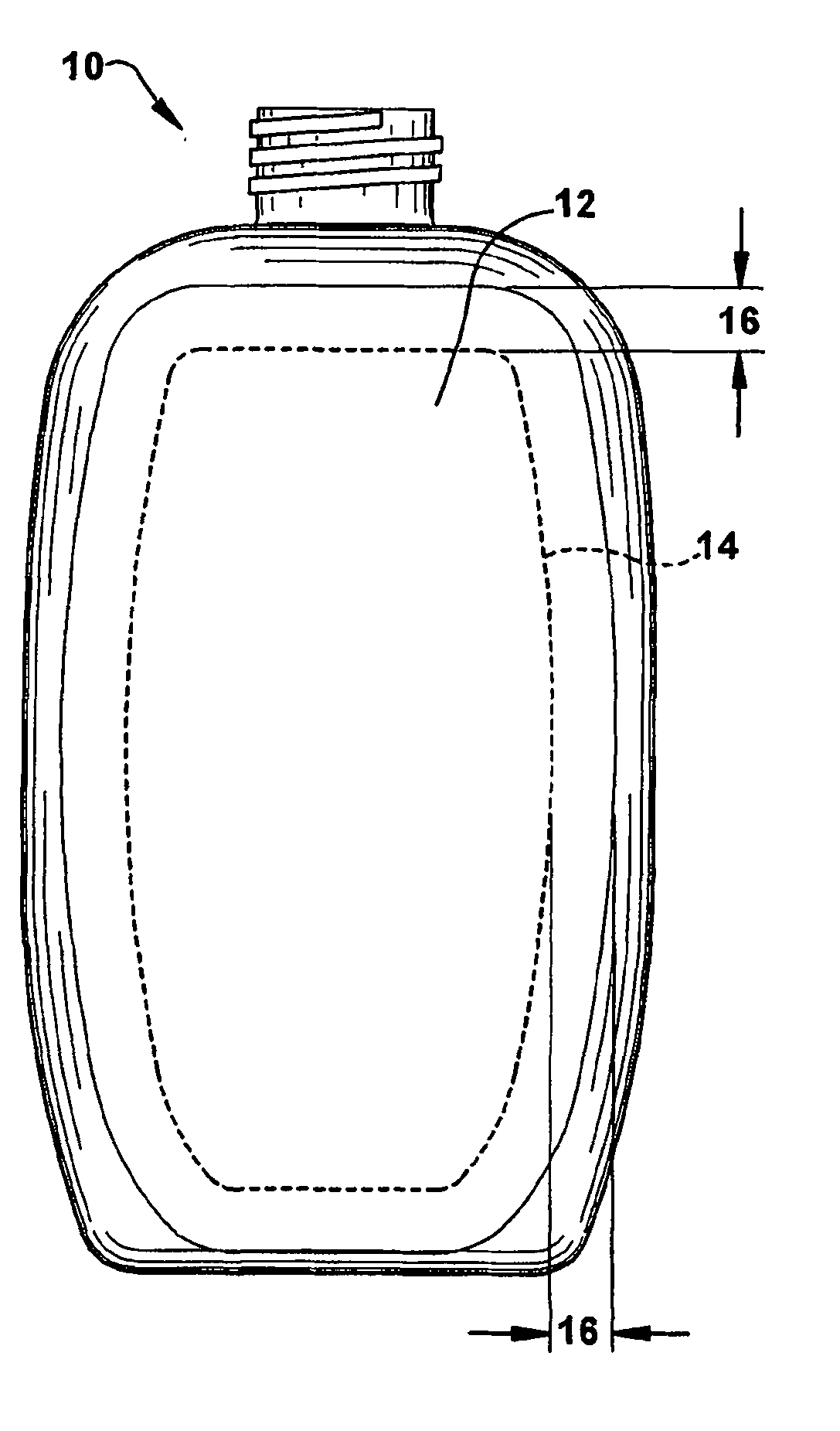

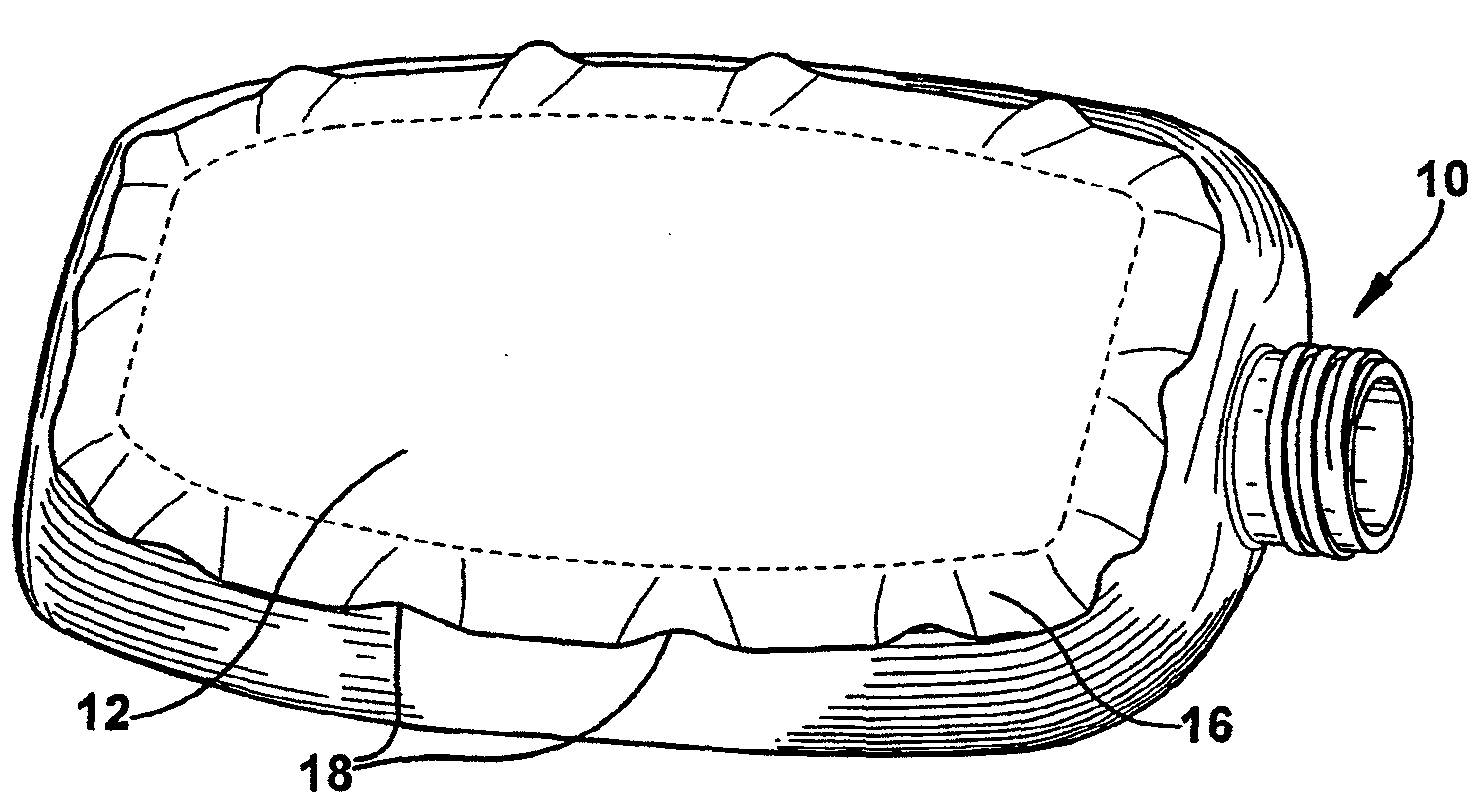

[0119] The pressure sensitive shrink labels were manufactured from 3 mil thick low density polyethylene multilayer shrink film named CorrTuff from Sealed Air. The film was coated with acrylic emulsion adhesive S692N from Avery Dennison. The adhesive was supported on cellophane BG-40, a silicone coated release liner. The labels are oversized, measuring approximately 5 by 3.5 inches, which is 20% larger than the industry standard recommended label size for the bottle to which the label is applied.

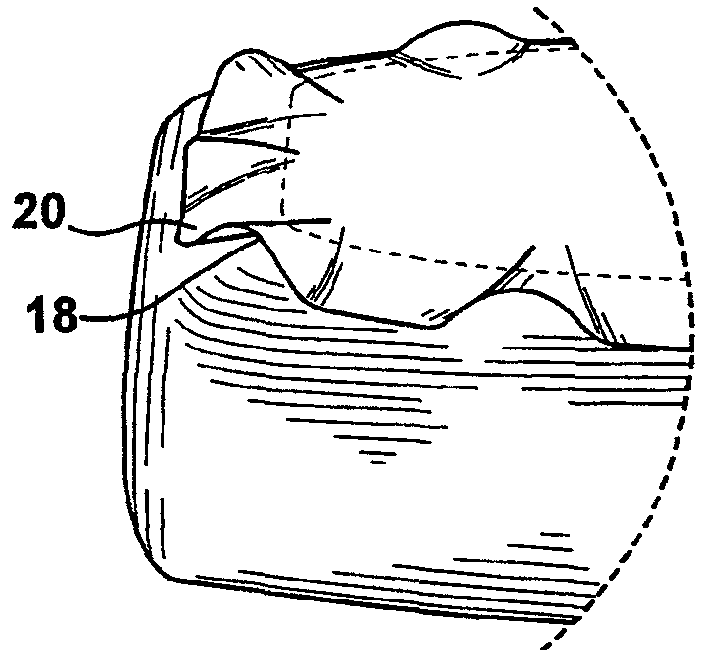

[0120] Toric 15 oz Johnson & Johnson Baby Lotion bottles were filled with water, capped, and processed with a Label-Aire 9000 Series labeling machine at 100 bottles per minute (BPM). The labeling machine is equipped with dual feed screws, matching speed upper and lower belts, Label-Aire2115-CD labeling head, high torque stepper motor drive. Presses down on the label with a walking beam type wiper, providing direct, center-out force to draw trapped air under the label and resulting ...

Embodiment 2

[0123] According to the method described in Example 1, a pressure sensitive shrink label made of a 2 mil thick polypropylene multilayer shrink film designated CZPA 200 from Innovia was applied to a bottle with a toric surface. After the initial rubbing, medium-sized protrusions were formed. The bottles and labels were heated to 100°C with high velocity hot air. The protrusions shrink after heating and are easy to wipe flat. The protrusions do not reappear after aging.

Embodiment 3

[0125] According to the method described in Example 1, a pressure sensitive shrink label made from a 2 mil thick polylactic acid monolayer shrink film designated EARTHFIRST PLA from Plastic Suppliers was applied to a bottle with a toric surface. After the initial rubbing, medium-sized protrusions were formed. The bottles and labels were heated to 70°C with high velocity hot air. The protrusions shrink after heating and are easy to wipe flat. The protrusions do not reappear after aging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com