A kind of arsenic-removing adsorbent in the pyrolysis process of urban waste

A technology for treating process and urban waste, applied in solid waste removal, chemical instruments and methods, transportation and packaging, etc., can solve the problem of inability to meet the harmless requirements of removing arsenic poisons, low ability to remove reduced arsenic, removal of arsenic Limited effect and other problems, to achieve the effect of increasing active adsorption sites, low cost, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

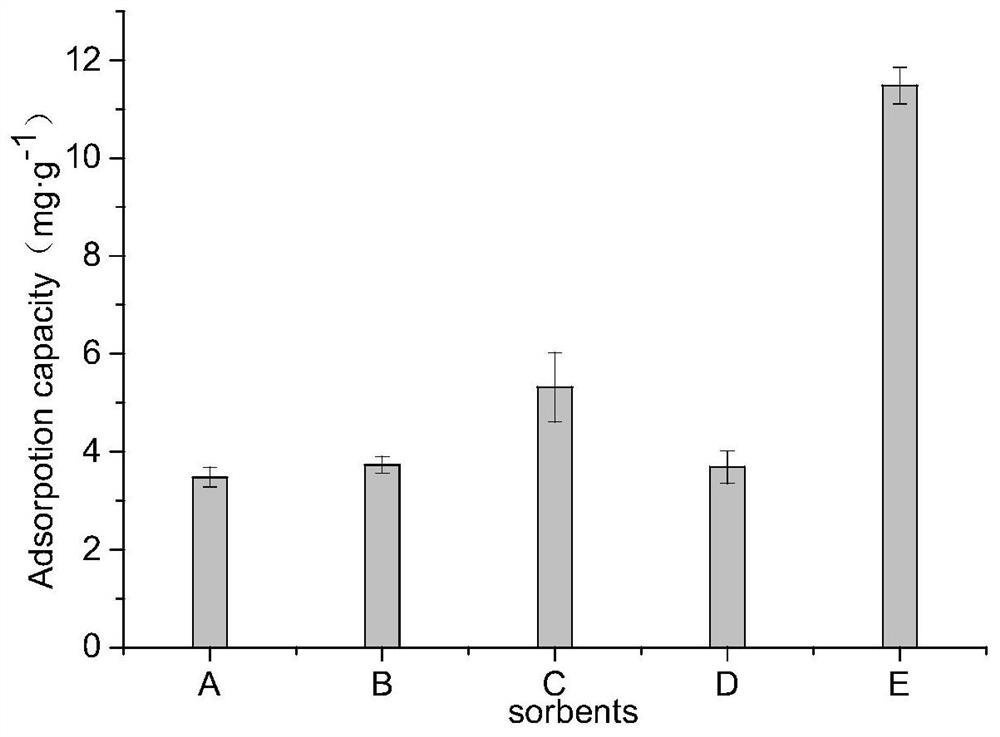

Embodiment 1

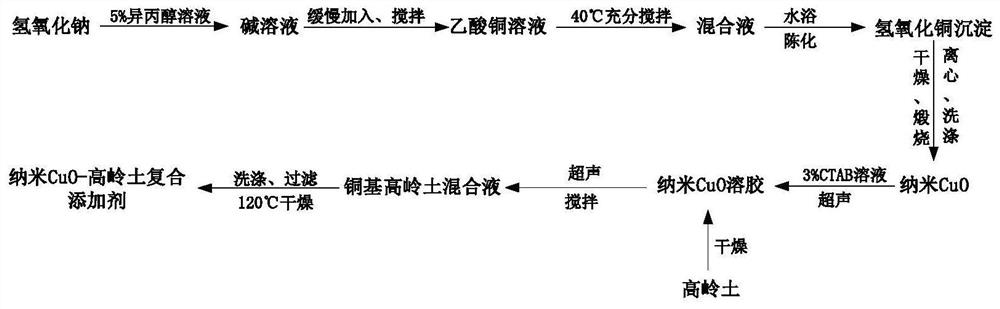

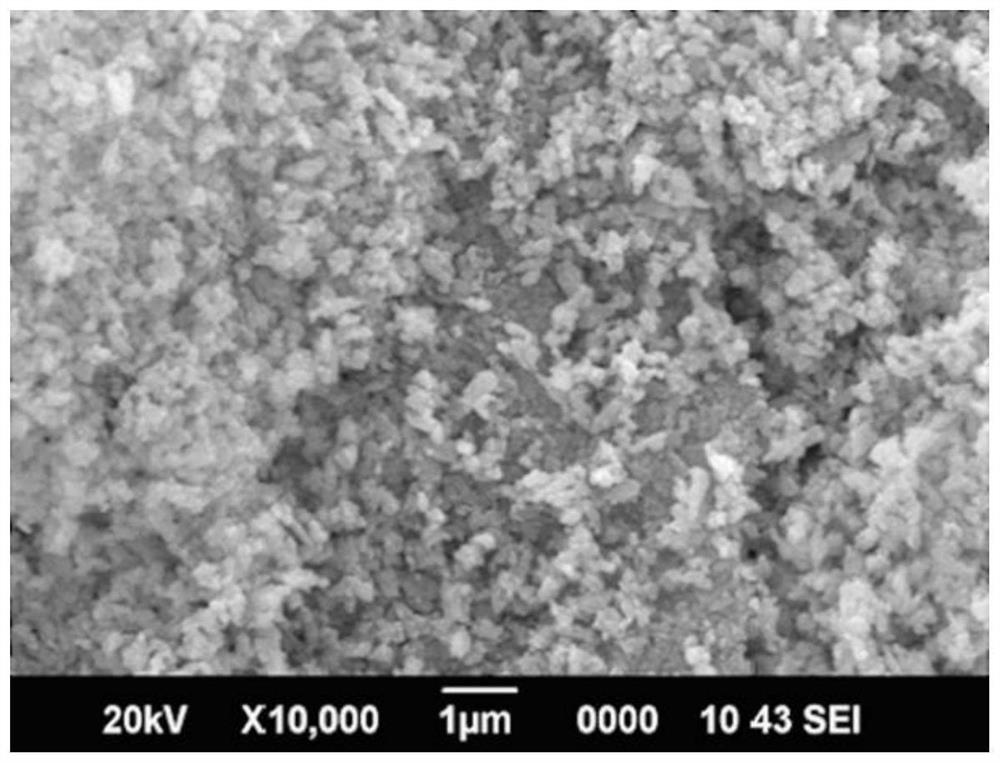

[0032] (1) Configure 0.2M copper acetate solution, 1M sodium hydroxide solution and add 5% isopropanol to it. After fully reacting, take a water bath at 65°C, age for 2 hours, centrifugally filter, wash with deionized water and precipitate in a muffle furnace Calcined at 400°C for 2 hours, then ground to obtain nano-copper oxide powder. Take 0.1g nano-CuO (ultrasonic 6min, ultrasonic frequency 15kHz) and pour it into 3% cetyltrimethylammonium bromide aqueous solution, sonicate in an ultrasonic cell pulverizer for 6min, ultrasonic frequency 15kHz to disperse to form CuO sol;

[0033] (2) Dry the kaolin in an oven at 105°C, take out 7g of dried kaolin powder from the oven, add it to the nano-CuO sol, ultrasonicate, take out the mixed solution and stir, filter, wash and dry to prepare the arsenic-removing adsorbent. The mass ratio of kaolin to nano copper oxide is 70:1; the ultrasonic time is 12min, the ultrasonic frequency is 25kHz; the stirring time is 15min, the washing times ...

Embodiment 2

[0034] Example 2 An arsenic-removing adsorbent in the process of pyrolysis treatment of urban waste, characterized in that it is prepared and obtained by the following method:

[0035] (1) Weigh copper acetate, sodium hydroxide and kaolin, fully dissolve copper acetate in deionized water, dissolve sodium hydroxide in 5% isopropanol solution; keep stirring the copper solution, and slowly add hydrogen into the solution at the same time The isopropanol solution of sodium oxide is fully stirred and aged in a water bath; the obtained copper hydroxide precipitate is centrifugally filtered, washed with water first, then washed with ethanol, dried in an oven at 80°C, calcined, and ground to obtain nano CuO powder; add nano-CuO powder to 3% cetyltrimethylammonium bromide aqueous solution, and ultrasonically disperse to form CuO sol; the temperature of the water bath is 55°C, the aging time is 2h; the drying time is 1h ; The calcination temperature is 350° C., the ultrasonic time is 5 m...

Embodiment 3

[0037] Example 3 An arsenic-removing adsorbent in the process of pyrolysis treatment of urban waste, characterized in that it is prepared and obtained by the following method:

[0038](1) Weigh copper acetate, sodium hydroxide and kaolin, fully dissolve copper acetate in deionized water, dissolve sodium hydroxide in 5% isopropanol solution; keep stirring the copper solution, and slowly add hydrogen into the solution at the same time The isopropanol solution of sodium oxide is fully stirred and aged in a water bath; the obtained copper hydroxide precipitate is centrifugally filtered, washed with water first, then washed with ethanol, dried in an oven at 80°C, calcined, and ground to obtain nano CuO powder; add nano-CuO powder to 3% cetyltrimethylammonium bromide aqueous solution, and ultrasonically disperse to form CuO sol; the temperature of the water bath is 80°C, the aging time is 4h; the drying time is 2h ; The calcination temperature is 500° C., the ultrasonic time is 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com