Method for manufacturing a cement clinker, and cement clinker manufacturing facility

A technology of cement clinker and equipment, applied in the field of manufacturing cement clinker, can solve problems such as multi-NOx gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

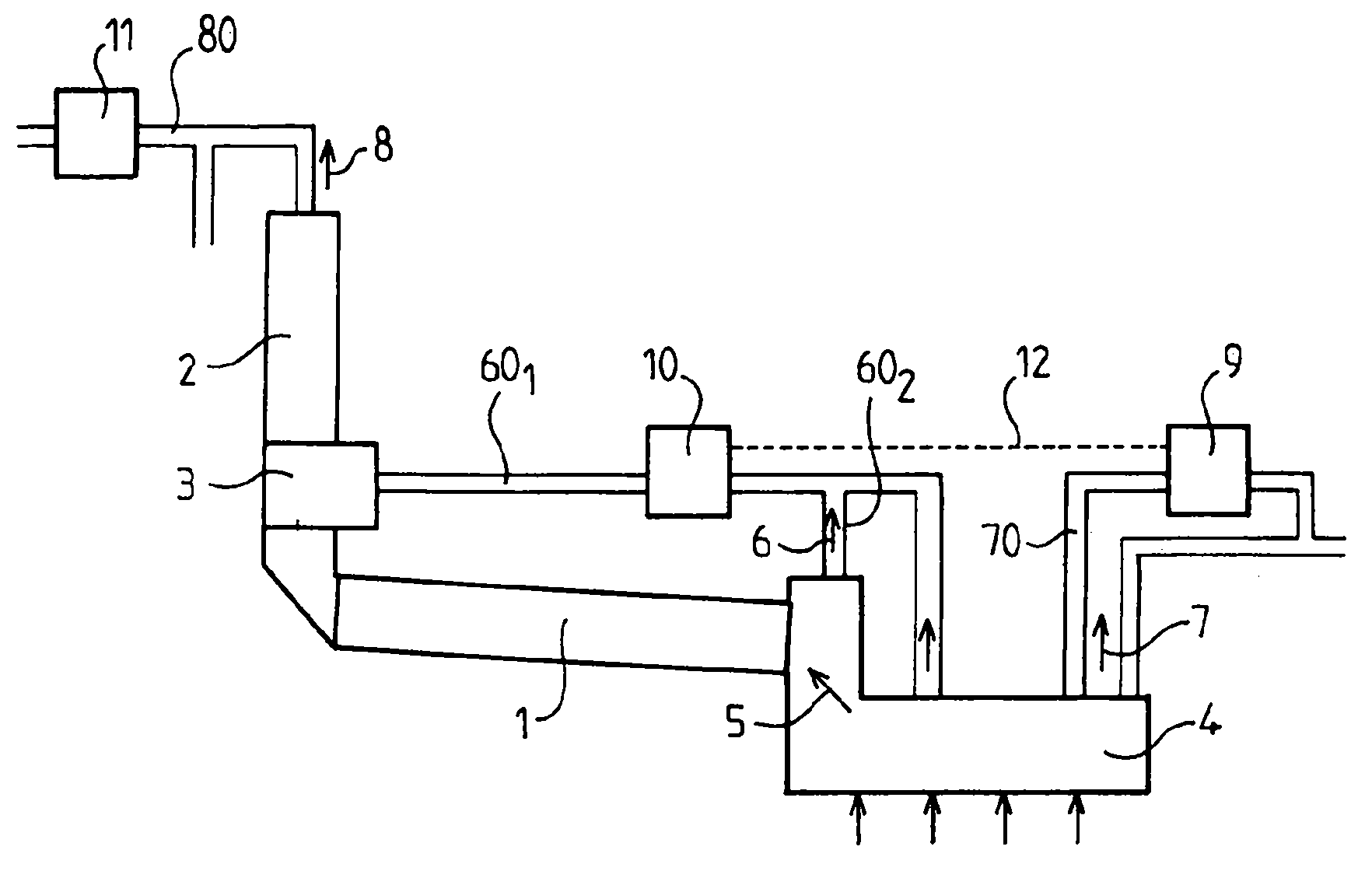

[0072] Example 1 (Prior Art):

[0073] The considered plant, as known in the prior art, is a clinker production unit of medium scale, or representing the capacity of a large number of existing units, producing 5000 tons of clinker per day. This plant consumes 3000 kJ supplied in the form of fuel per kg of clinker produced, of which 62.8% is introduced at the precalciner. Thus, the power generated from the fuel in the precalciner was 108.8 MW.

[0074] Clinker cooler especially produces: 117000Nm 3 / h, tertiary air at 890°C, which is supplied to the combustion of the pre-calcination reactor; 210000Nm 3 / h, exhaust air at 245°C. The flow rate of the smoke in the cyclone preheater is 286200Nm 3 / h at a temperature of 320°C.

[0075] An exchanger located on the exhaust air route of the cooler reduces the temperature of the gas from 245°C to 135°C and exchanges 8.6 megawatts of power. Considering the possible low temperature of the fluid of the exchanger, as long as a fluid...

example 2

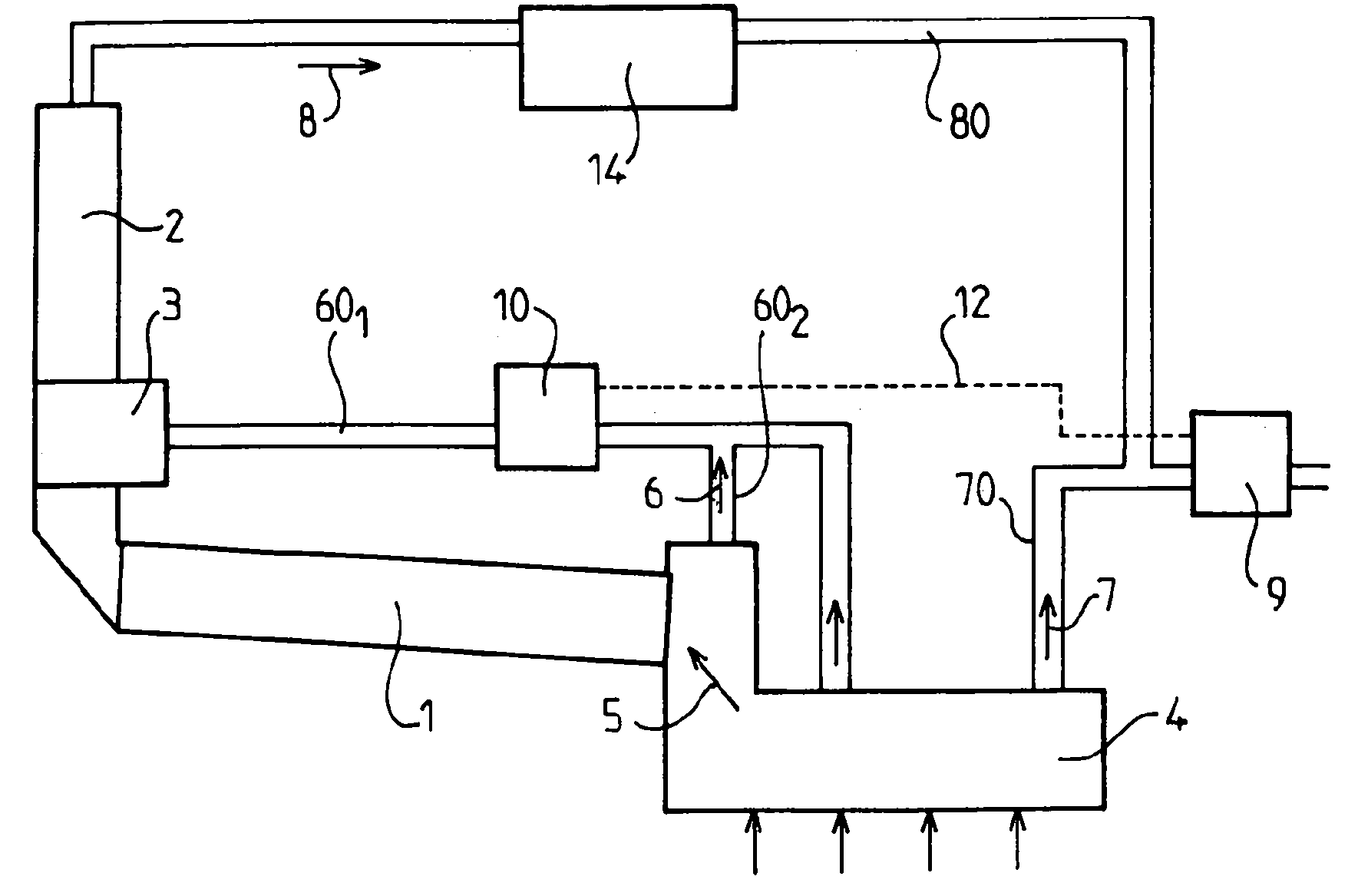

[0079] Consider the plant according to example 1 of the invention, in which an exchanger is placed in the route of the tertiary air and reduces the temperature of the tertiary air to 700°C. The amount of fuel introduced into the pre-calcination reactor must be increased, and the new operating conditions of the plant are described below.

[0080] The power generated from the fuel in the precalciner was 117.8 MW. Clinker Cooler now produces 127900Nm 3 / h, 860°C tertiary air, and 199200Nm 3 / h, exhaust air (excess air) at 235°C. The flow rate of the smoke in the cyclone preheater is 300000Nm 3 / h at a temperature of 335°C.

[0081] The exchanger (second exchanger) located on the route of the tertiary air, which reduces the temperature of the tertiary air from 860°C to 700°C, exchanges 8.3 MW of power. An exchanger (first exchanger) located on the route of the exhaust air (excess air) of the cooler reduces the temperature of the gas from 235°C to 135°C and exchanges 7.4 MW of...

example 3

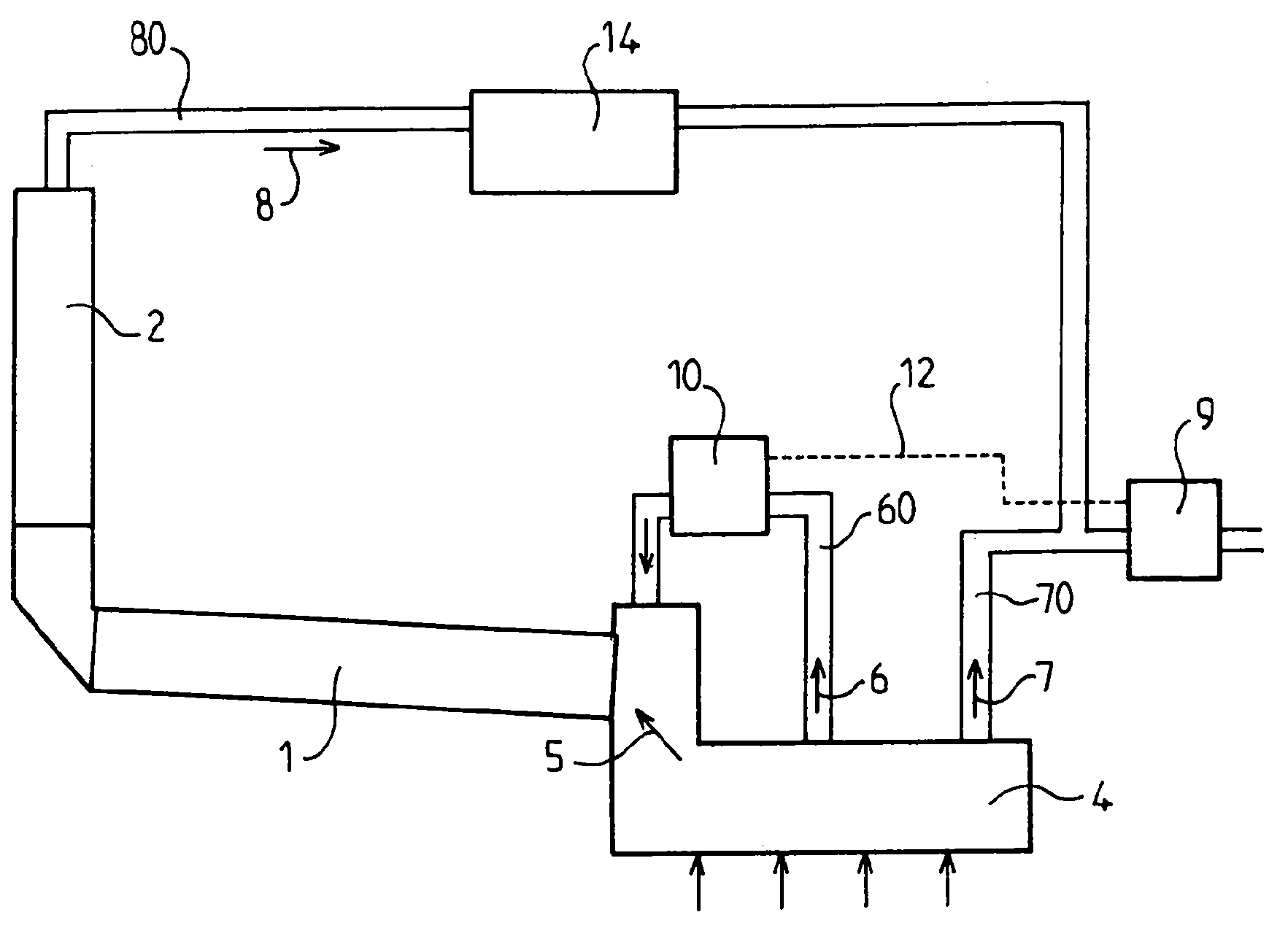

[0084] Consider the plant according to example 2 of the invention, in which 50% of the flue from the cyclone preheater is used to dry the feedstock.

[0085] The preheater plume is split in two. Not used for dry materials, 150000Nm 3 The first partial flow per hour is directed through an exchanger (third exchanger) and lowers the gas from 335°C to 135°C, exchanging 13.1 MW of power. Said switch is connected to two other switches (first switch and second switch), thus having a total power of 28.8 megawatts. The conversion efficiency reached 28%, producing 8.06 megawatts of electricity.

[0086] The marginal efficiency of the additional energy provided by the fuel (ie 9 MW) is 56% compared to Example 1 which has a recoverable energy of 3.02 MW. This value is comparable to the efficiency of modern thermal power plants using solid fuels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com