Plasma processing apparatus

A plasma and processing device technology, which is applied in the field of plasma processing devices, can solve problems such as ununiform processing of the treated surface and uneven plasma, and achieve the effects of eliminating metal pollution, reducing usage, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

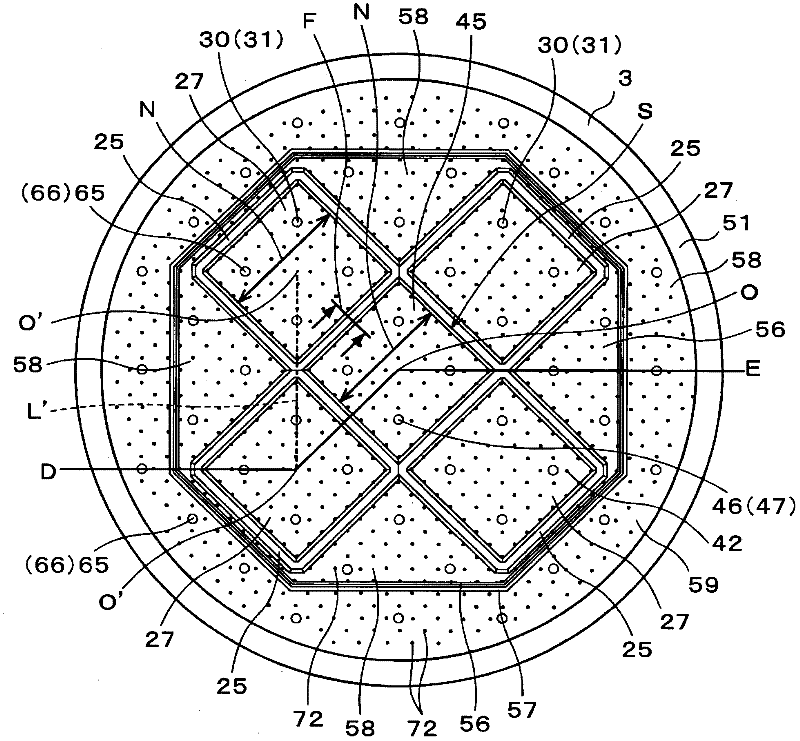

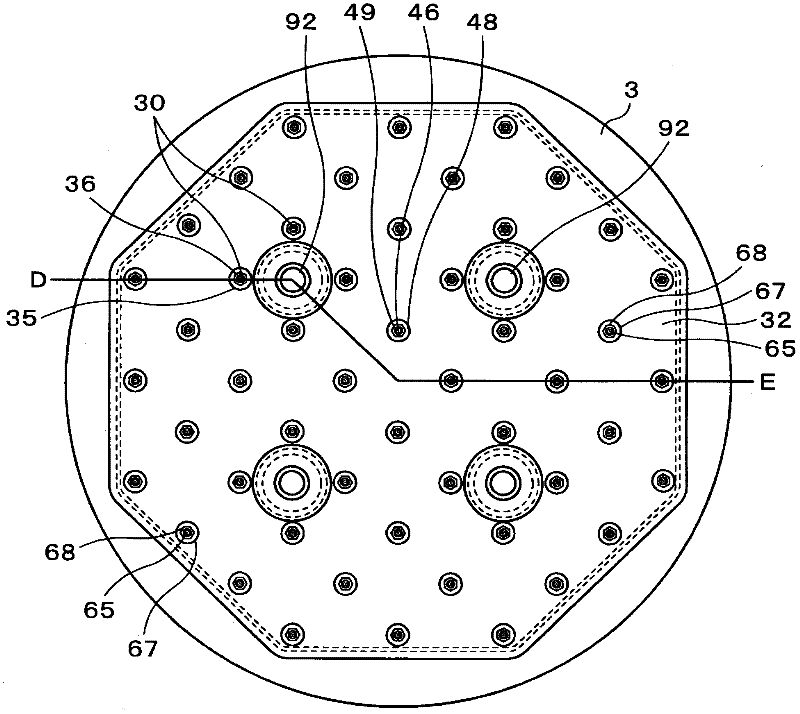

[0207] Figure 15 It is a bottom view of the cover 3 of the plasma processing apparatus 1 according to Modification 1. FIG. In the plasma processing apparatus 1 according to Modification 1, a cover made of, for example, Al 2 o 3 Eight dielectric bodies 25 are formed. Same as before, such as Figure 7 As shown, each dielectric body 25 has a substantially square plate shape. The respective dielectric bodies 25 are arranged such that their apex angles are adjacent to each other. In addition, among the adjacent dielectric bodies 25, the apex corners of the respective dielectric bodies 25 are arranged adjacent to each other on the line L' connecting the center point O'. In this way, eight dielectric bodies are arranged so that their apex angles are adjacent to each other and the apex angles of each dielectric body 25 are adjacent to each other on the line connecting the center points O' of the adjacent dielectric bodies 25. The dielectric body 25 can thereby form a square reg...

Deformed example 2

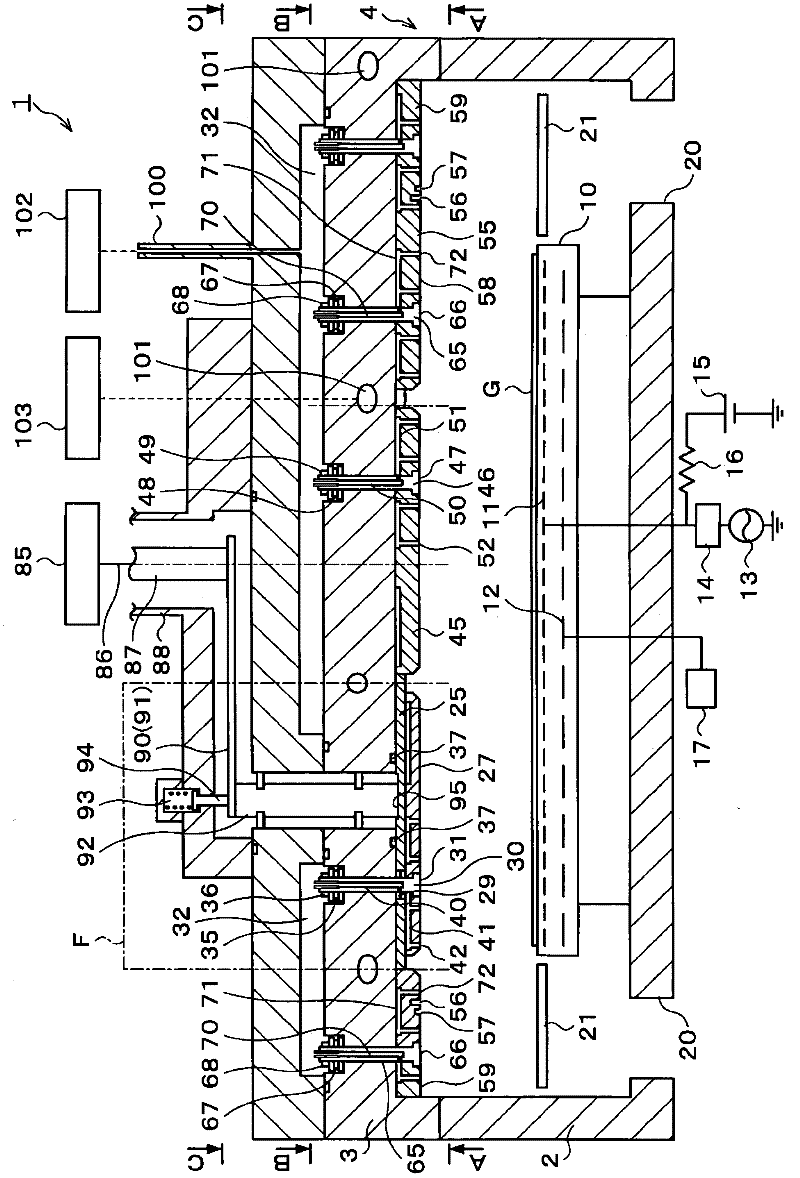

[0220] Figure 16 It is a longitudinal cross-sectional view showing a schematic configuration of a plasma processing apparatus 1 according to Modification 2 ( Figure 17 D-O'-O-E section in). Figure 17 yes Figure 16 A-A sectional view in . In the plasma processing apparatus 1 according to Modification 2, a cover made of, for example, Al 2 o 3 Eight dielectric bodies 25 are formed. Same as before, such as Figure 7 As shown, each dielectric body 25 has a substantially square plate shape. The respective dielectric bodies 25 are arranged such that their apex angles are adjacent to each other. In addition, among the adjacent dielectric bodies 25, the apex corners of the respective dielectric bodies 25 are arranged adjacent to each other on the line L' connecting the center point O'. In this way, eight dielectric bodies are arranged so that their apex angles are adjacent to each other and the apex angles of each dielectric body 25 are adjacent to each other on the line co...

Deformed example 3

[0227] Figure 18 It is a vertical cross-sectional view showing a schematic configuration of a plasma processing apparatus 1 according to Modification 3 ( Figure 19 D-O’-O-E profile in ). Figure 19 yes Figure 18 A-A sectional view in . In the plasma processing apparatus 1 according to Modification 3, a cover made of, for example, Al 2 o 3 Four dielectric bodies 25 are formed. Same as before, such as Figure 7 As shown, each dielectric body 25 has a substantially square plate shape. The respective dielectric bodies 25 are arranged such that their apex angles are adjacent to each other. In addition, among the adjacent dielectric bodies 25, the apex corners of the respective dielectric bodies 25 are arranged adjacent to each other on the line L' connecting the center point O'. In this way, the apex angles of the dielectric bodies 25 are adjacent to each other, and the apex angles of the dielectric bodies 25 are adjacent to each other on the line L' connecting the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com