Method for controlling vibration hydraulic cylinder of crystallizer

A crystallizer vibration and control method technology, applied in the field of hydraulic cylinder control, can solve problems such as waveform distortion, large amplitude deviation, and fast dynamic response of the system, and achieve small waveform distortion and mechanical impact, small actual amplitude error, and dynamic response fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

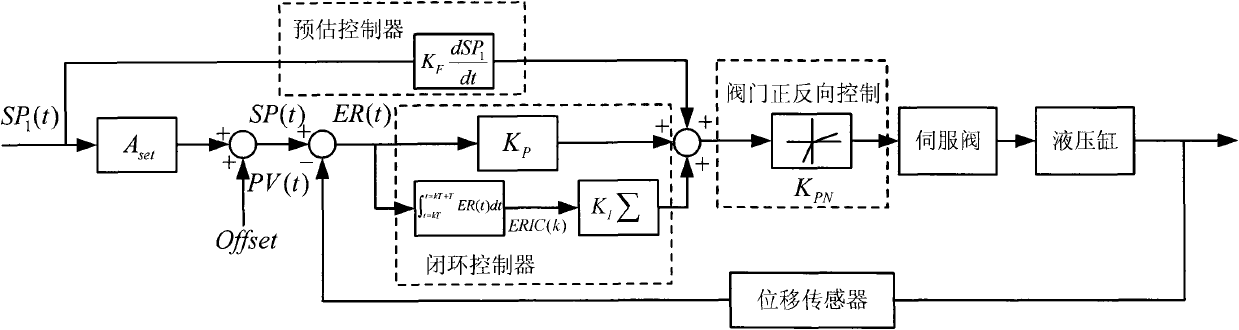

[0034] like figure 1 As shown, the present invention provides a control strategy for the hydraulic cylinder of the non-sinusoidal vibration device of the continuous casting machine crystallizer. The control strategy adopts the predictive controller with correction; adopts the improved PID controller; The opening degree of the servo valve is calculated by the concept of directional control, so as to ensure that the crystallizer can move precisely according to the preset trajectory.

[0035] Below in conjunction with accompanying drawing and formula, the present invention will be further described:

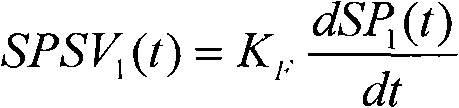

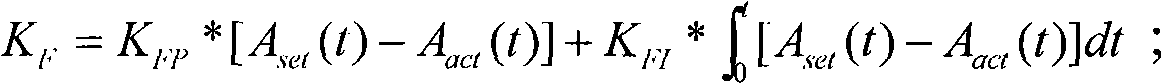

[0036] A control method for a crystallizer vibration hydraulic cylinder, which uses a corrected predictive controller, an integral improved PID closed-loop controller, and a valve forward and reverse control method to calculate the set value of the servo valve opening SPSV, any t The setting value SPSV(t) of the opening of the servo valve at any time is calculated by the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com