Large numerical control machine tool with quenching speed-regulating self-centering linkage function

A CNC machine tool, self-centering technology, applied in the direction of driving devices, metal processing machinery parts, turning equipment, etc., can solve the problems of long preparation auxiliary time, low production efficiency, narrow processing range, etc., to reduce the labor intensity of workers, work High efficiency and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

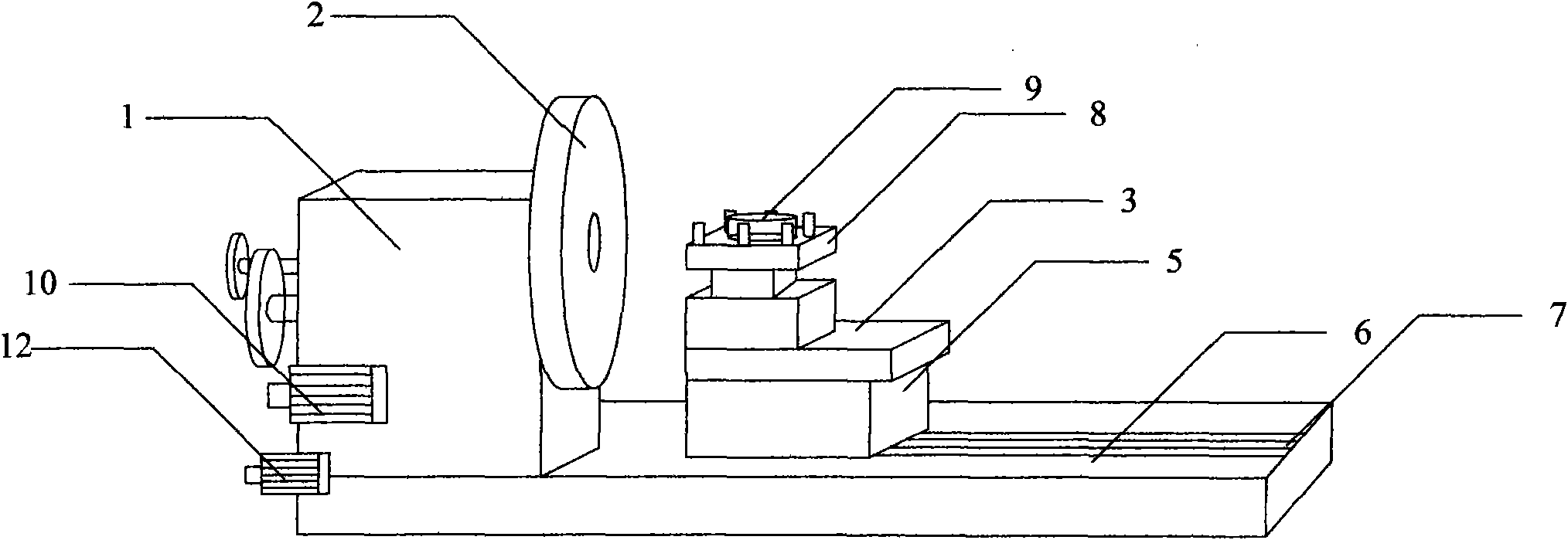

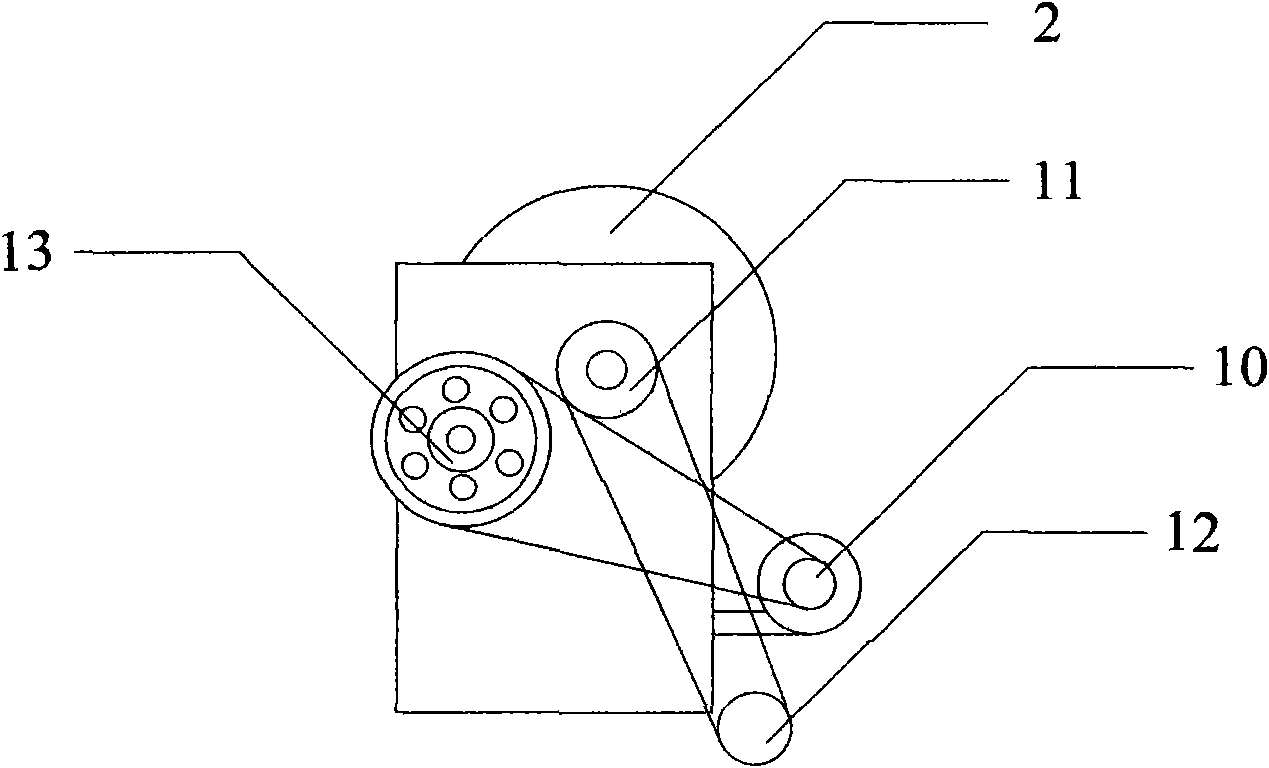

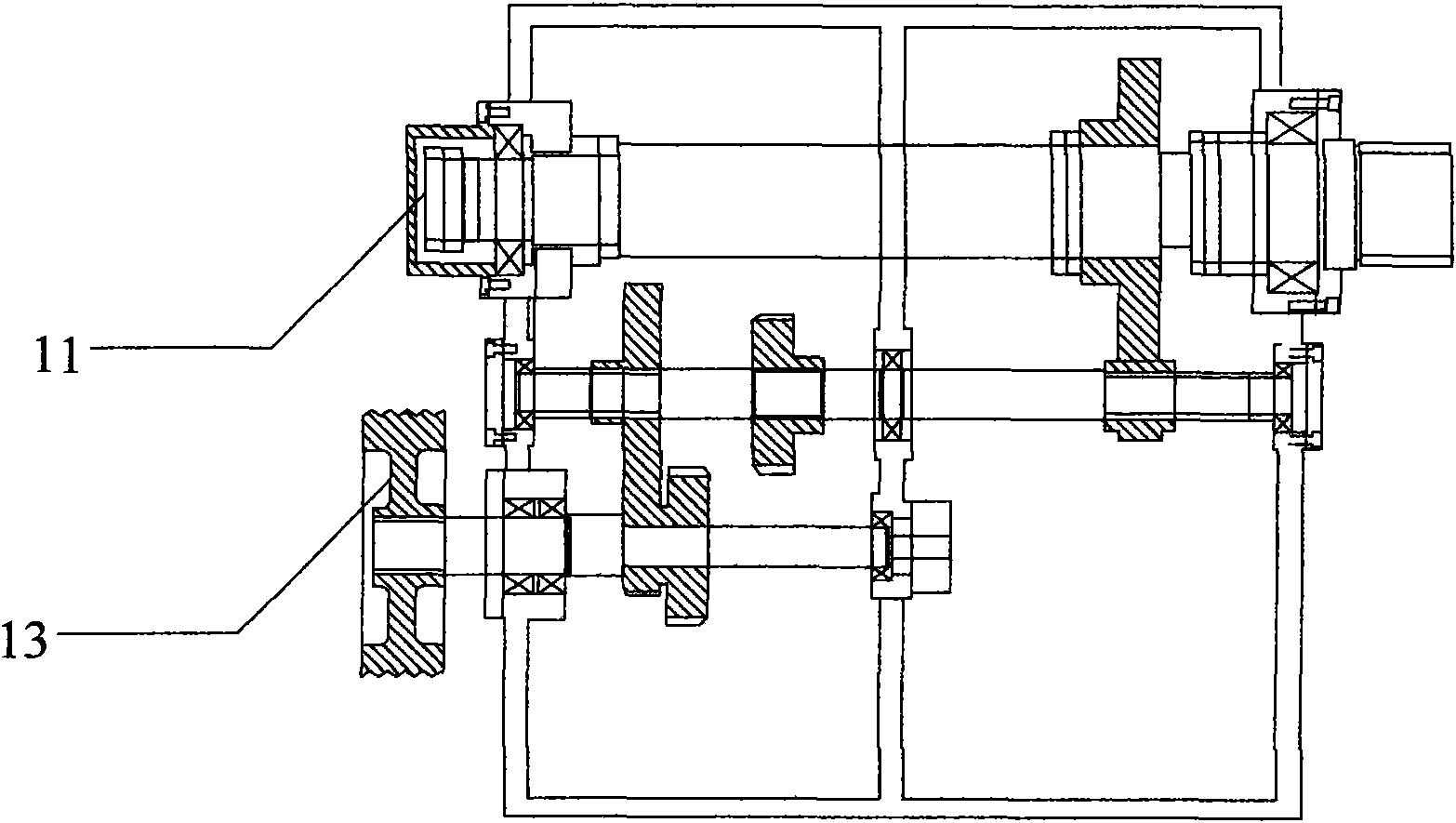

[0015] The specific embodiment of the present invention is as follows: a large-scale numerically controlled machine tool with quenching speed regulating self-centering linkage function, including a chuck mechanism, a turning mechanism and an electric control system, the chuck mechanism includes a spindle box 1 and an automatic The centering chuck 2, the turning mechanism includes a machine bed 3 and a tool rest device installed on the bed, the machine bed 3 includes a base plate 6 and a base 5 installed on the base plate, and movable convex rails are set on the base plate 6 7. Corresponding grooves are set on the bottom surface of the machine base 5, so that the machine base 5 can be slidably installed on the bottom plate 6, and the machine bed 3 can slide freely along the groove on the bottom surface of the machine base 5; the tool rest device includes a turret knife Frame 8 and the gear-changing tool motor 9 installed on the turret turret 8, the motor is connected with the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com