Deburring device for blank of annular magnetic product

A deburring and magnetic technology, which is applied to machine tools, grinding machines, and metal processing equipment suitable for grinding workpiece edges, can solve problems such as unstable production quality, collision of grinding media, and missing corners on the product surface, so as to improve production efficiency And the effect of production quality stability, high cleanliness, and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

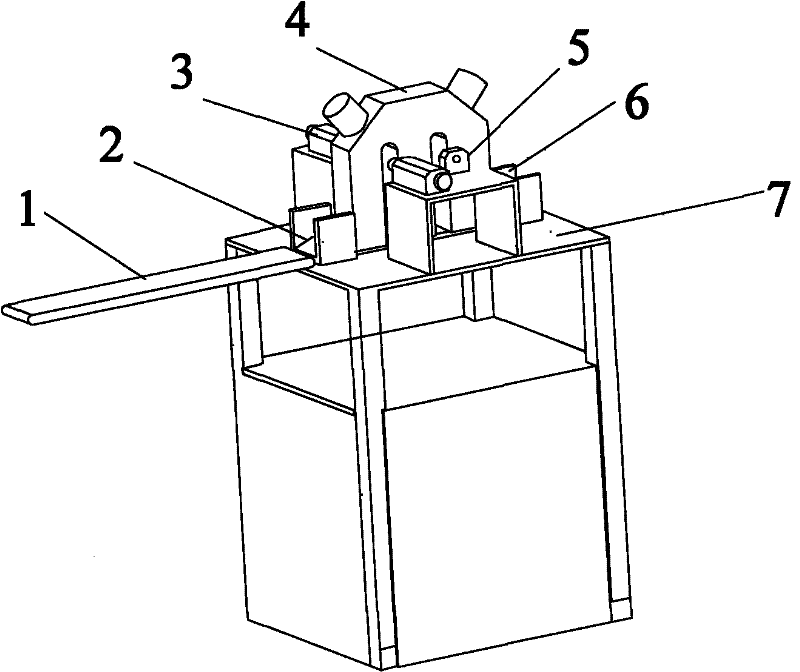

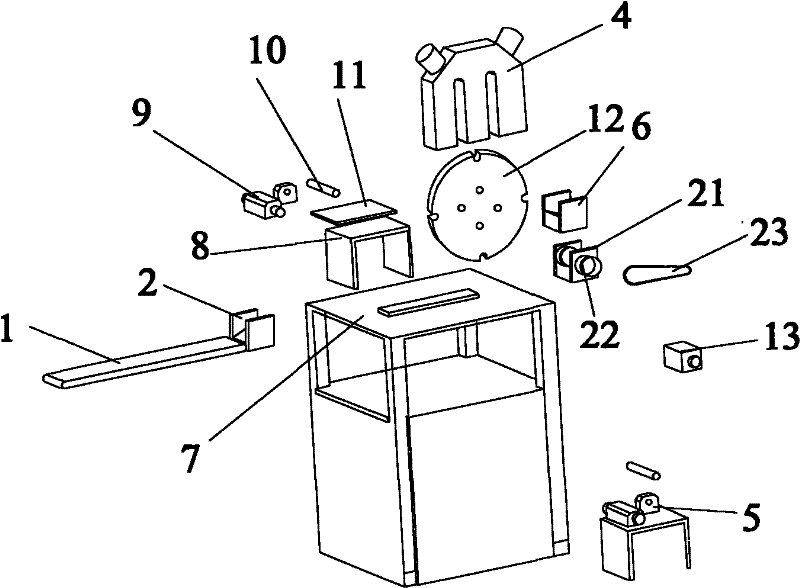

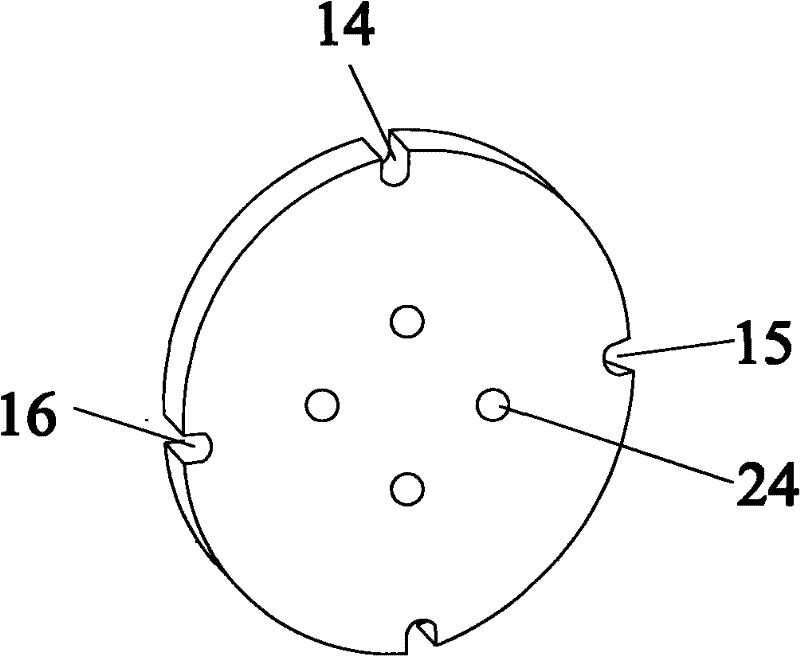

[0029] Figure 1~5 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the ring-type magnetic product raw body deburring device includes a stand 7, a grinding mechanism 3, a turntable mechanism and a control device. The grinding mechanism 3 and the turntable mechanism are all arranged above the stand 7, and the turntable mechanism is provided with several A slot 14 for positioning the raw body of the ring-shaped magnetic product. The grinding mechanism 3 is respectively arranged on the front and rear sides of the turntable mechanism, and is set corresponding to the slot hole 14 of the turntable mechanism. The two ends of the turntable mechanism are respectively connected with upper material mechanism and unloading mechanism; the control device is located inside the platform 7 and is connected to the grinding mechanism 3, the turntable mechanism, the feeding mechanism and the unloading mechanism respectively.

[0030] The turntable me...

Embodiment 2

[0042] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the number of slots in the turntable mechanism is 6, and they are evenly distributed on the turntable mechanism.

[0043] The blanking mechanism includes a blanking frame and a material receiving tray, and the blanking shelf is provided with a slope, the bottom of which is connected to the material receiving tray, and its top is set correspondingly to the slot on the right side of the turntable mechanism.

Embodiment 3

[0045] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the number of slots in the turntable mechanism is 10, and they are evenly distributed on the turntable mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com