Full-automatic glass diamond grinding and polishing machine

A glass water, fully automatic technology, used in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, grinders, etc. Low production efficiency and other problems, to achieve the effect of saving manpower, facilitating centralized processing and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

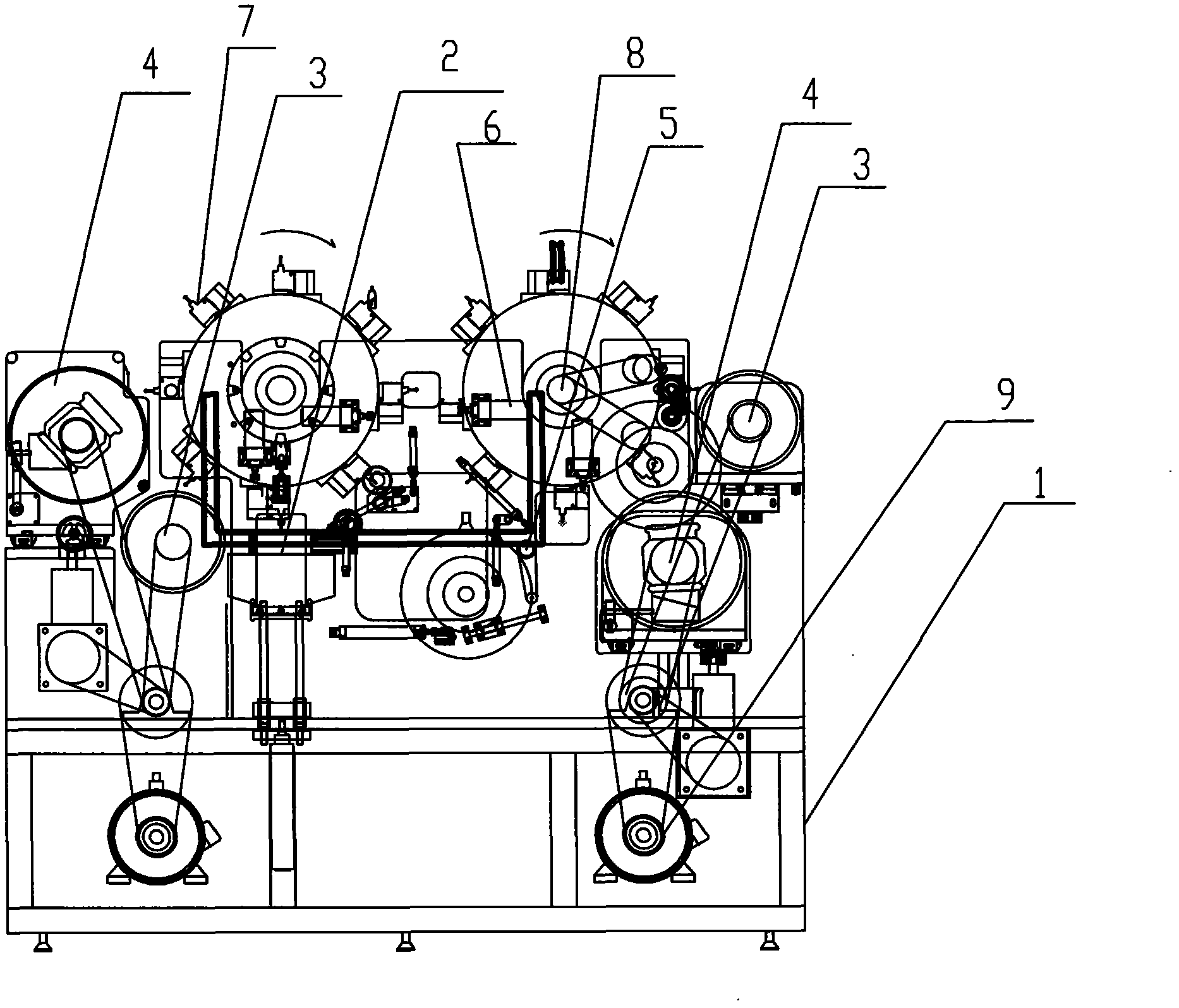

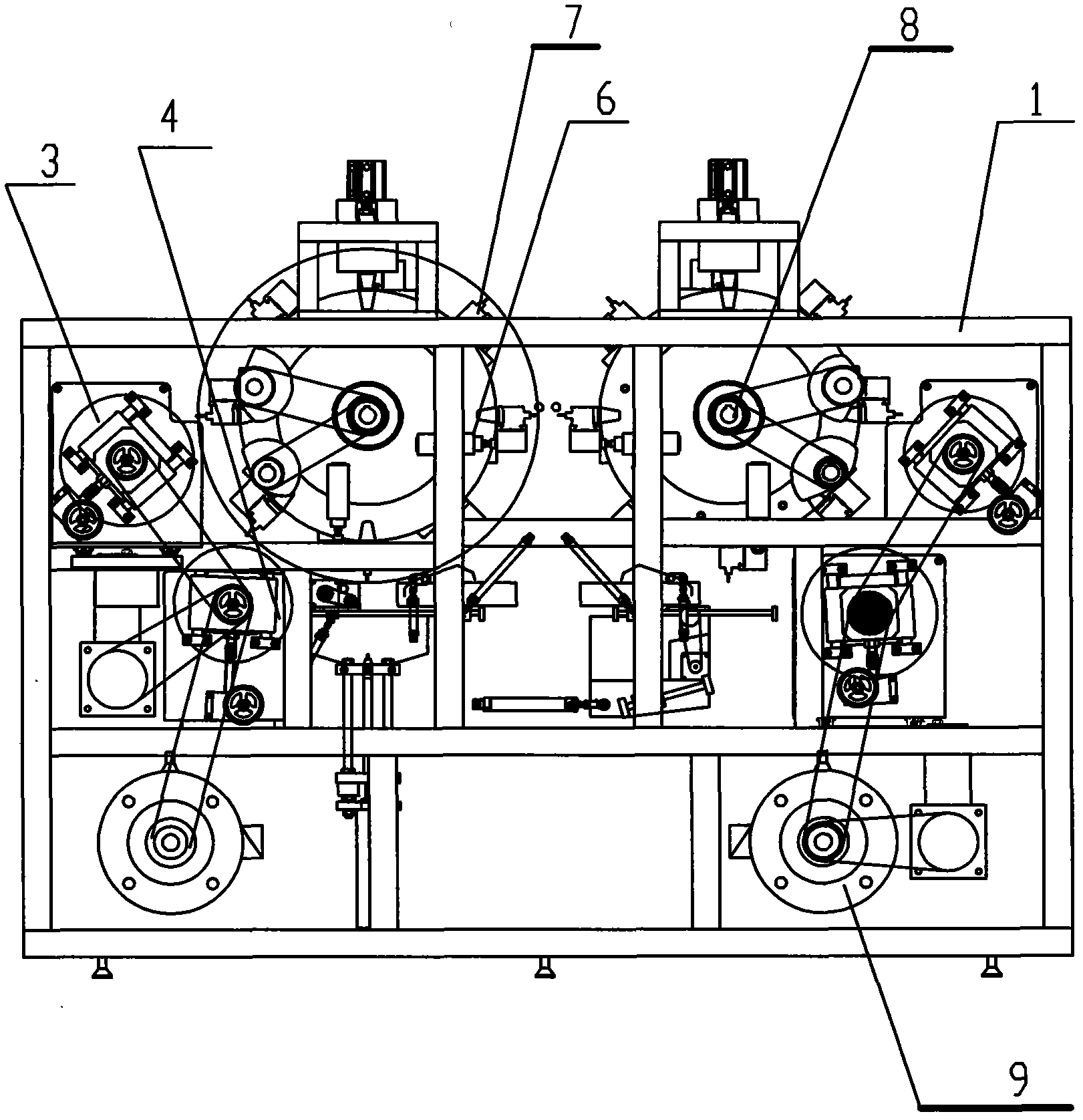

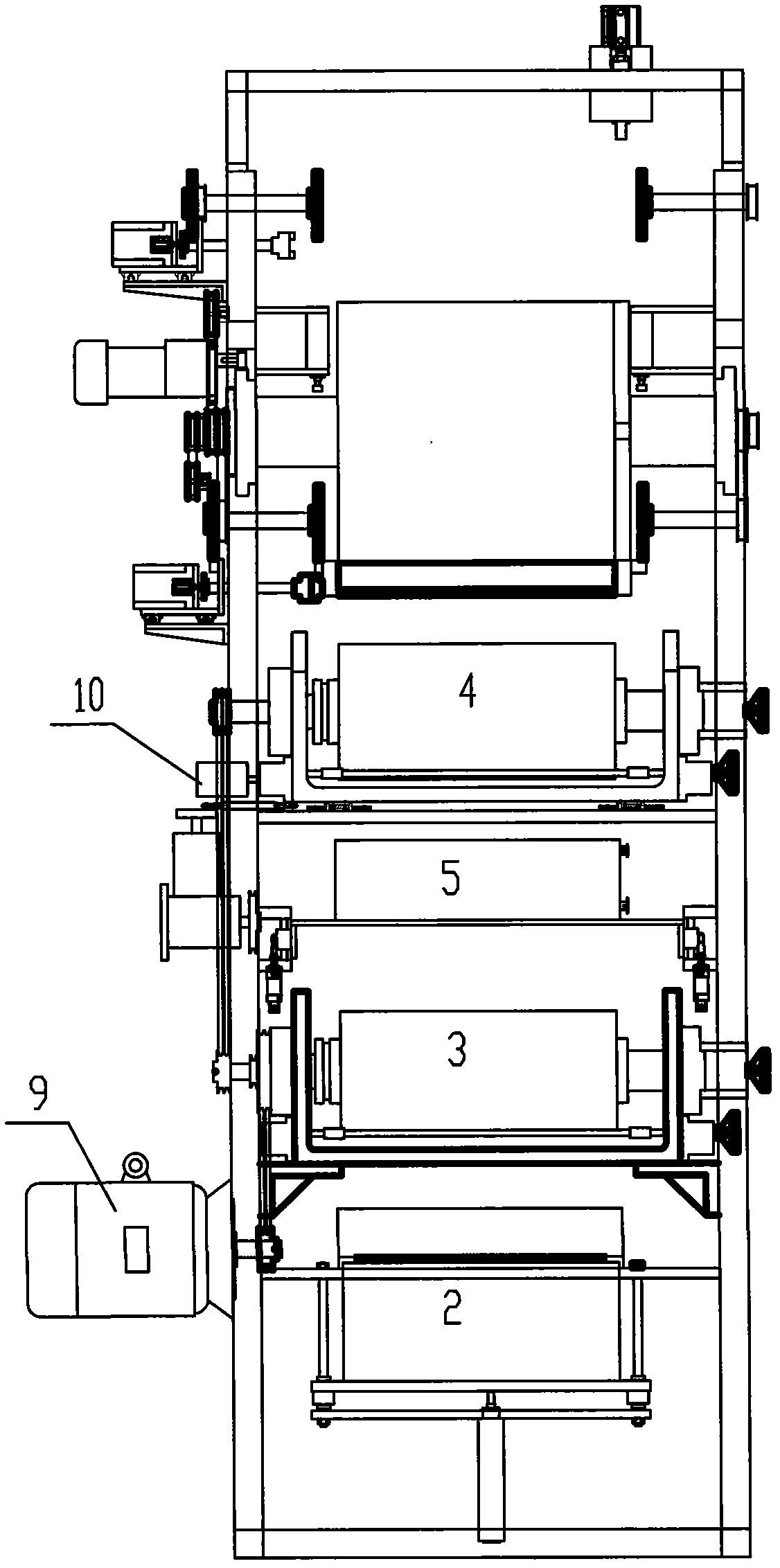

[0025] like figure 1 , figure 2 , image 3 As shown, the fully automatic glass rhinestone grinding and polishing machine of the present invention includes two rotating mechanisms 8 arranged on the frame 1, eight clamp devices 7 arranged on the rotating mechanism 8, and grinding wheel devices 3 distributed on the periphery of the rotating mechanism 8 With the throwing wheel device 4, the feeding device 2, and the unloading device 5, the clamp device 7 is equidistantly arranged on the circumference of the rotating mechanism 8, and the clamp device 7 includes a clamp that pushes out the cylinder 6 and its end, and is arranged above the clamp. There are jig pins and a stepping motor that drives the jig pins to rotate. The rotating mechanism 8 includes a drum, and two vertically distributed horizontally symmetrical drums are fixed side by side on the frame 1, and the circumferential outer edge of the fixture device on each rotating mechanism is longitudinally provided with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com