Universal crane for construction process of high-speed railway sound barrier

A technology for high-speed railways and sound barriers, applied in cranes, load suspension components, transportation and packaging, etc., can solve problems such as tight construction schedules and heavy construction tasks, and achieve the effects of reducing project cost, improving construction efficiency, and reducing work area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail with reference to the drawings.

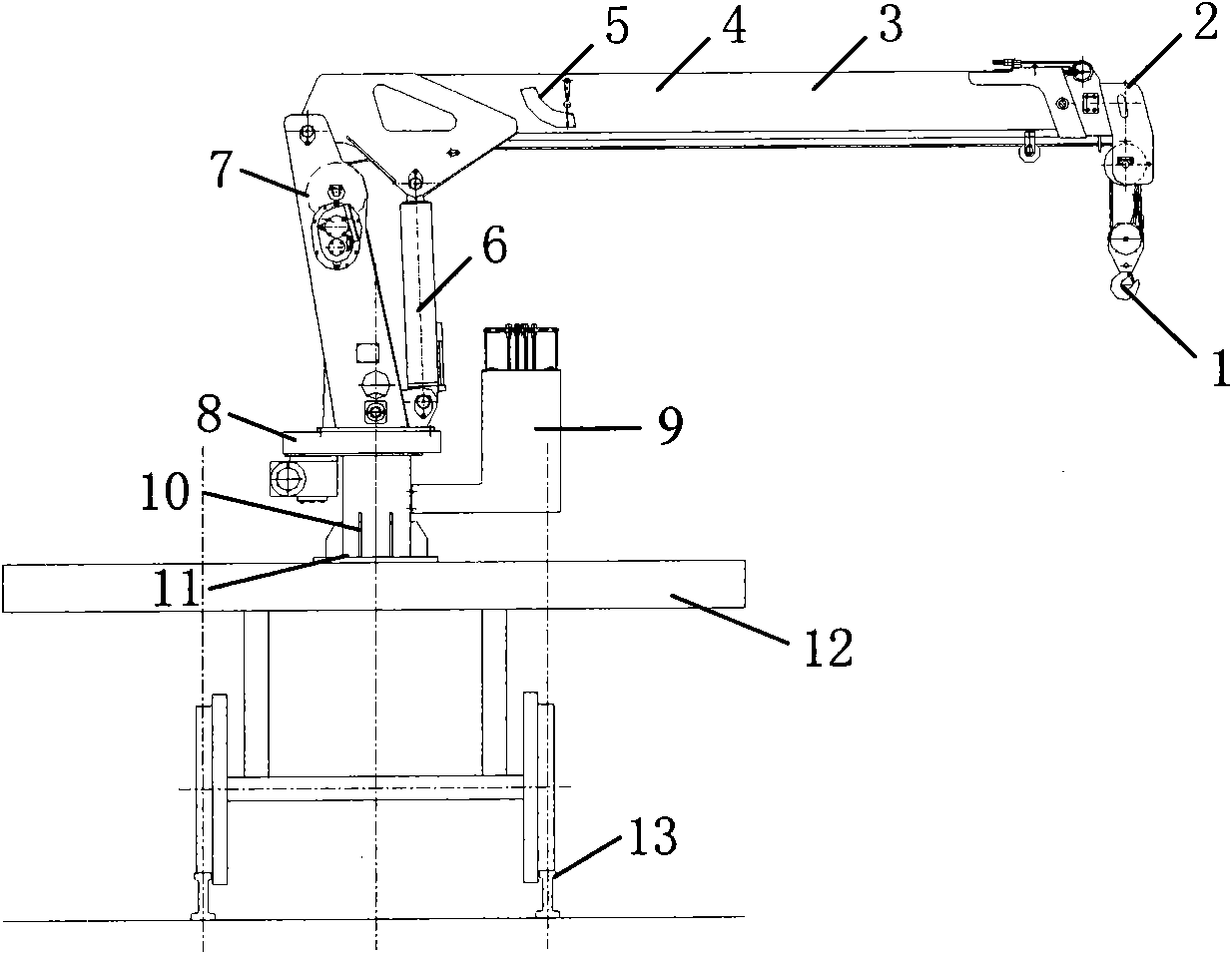

[0022] Such as figure 1 As shown, the universal sound barrier crane is composed of a base and an upper crane, which includes: 1. hook assembly, 2. telescopic boom (two sections), 3. basic boom, 4. telescopic cylinder (built-in), 5. amplitude indication Device, 6. Luffing cylinder, 7. Lifting mechanism, 8. Turntable, 9. Control mechanism, 10. Slewing base, 11. Flange, 12. General railway flat car, 13. Railway rail.

[0023] The upper crane is connected with a general railway flatbed car or a comprehensive maintenance vehicle through a flange, so that the universal sound barrier crane can complete the all-round hoisting operation of the sound barrier along the rail direction.

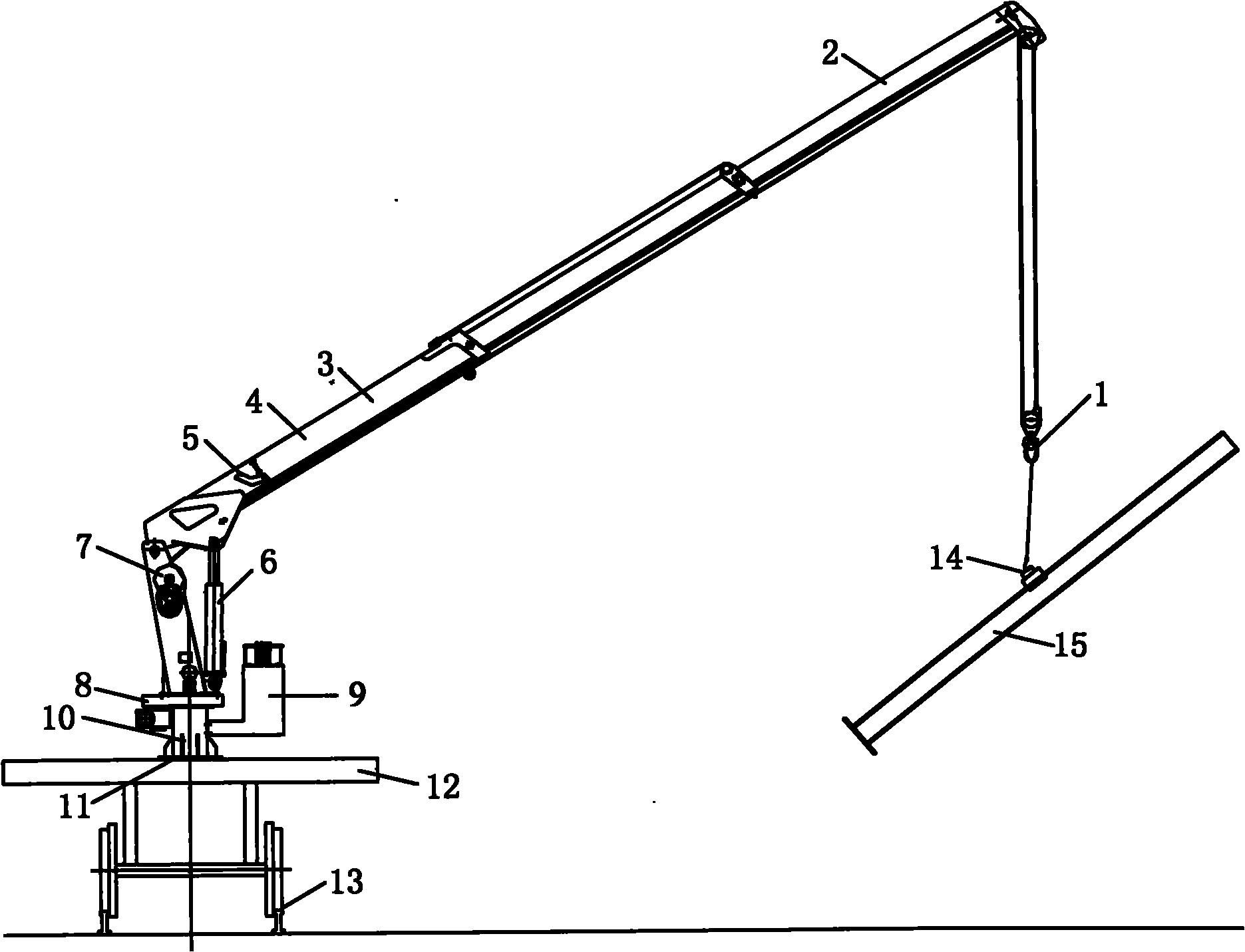

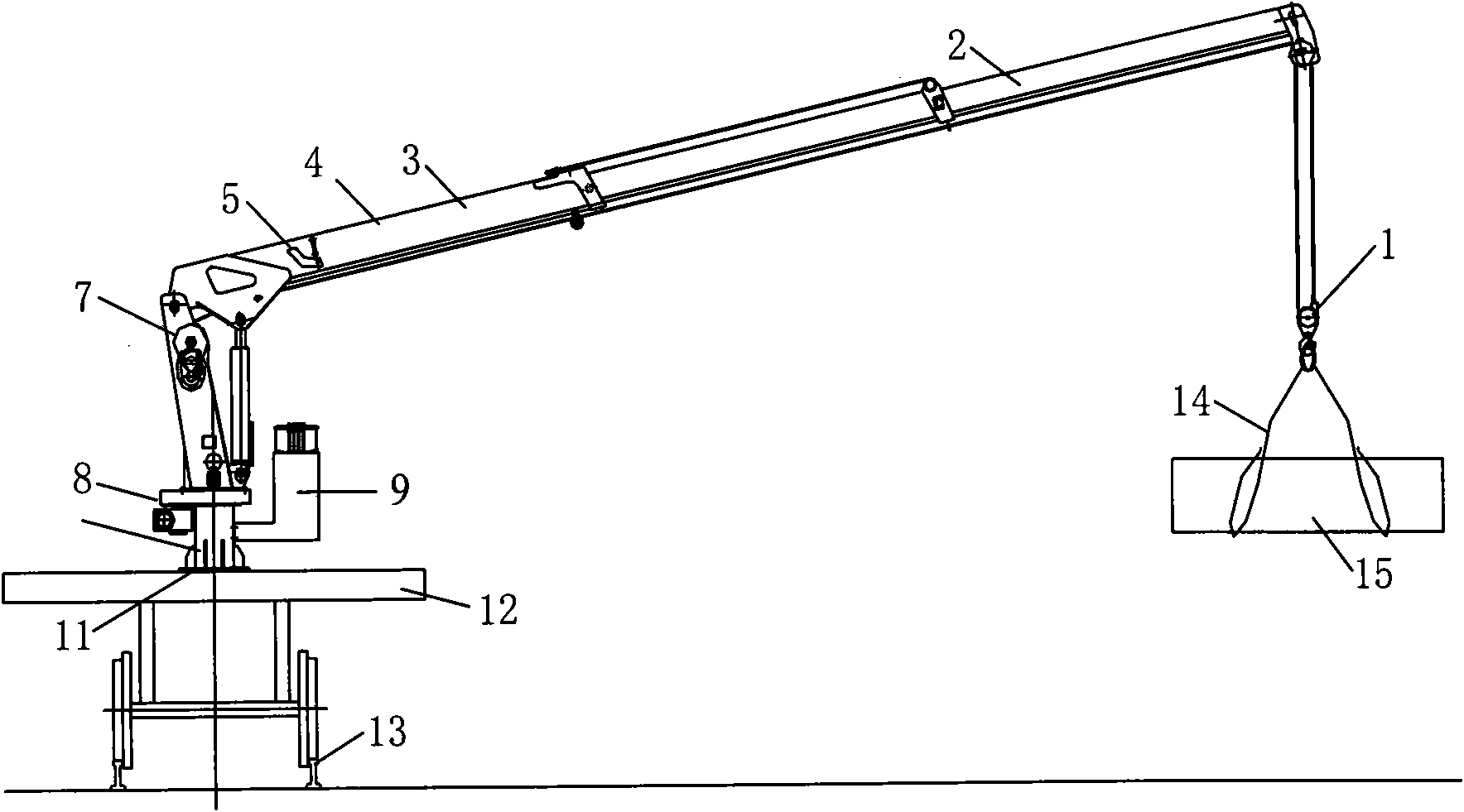

[0024] By replacing two different lifting fixtures at the end of the universal sound barrier crane, the lifting work of different component units of the sound barrier can be completed, such as figure 2 , As shown in 3.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com