Construction method of tunnel prefabricated structure

A prefabricated structure and construction method technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of large lifting equipment, shield tunnel construction, and occupation of tunnel transportation space, etc., to achieve firm connection and construction Fast, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

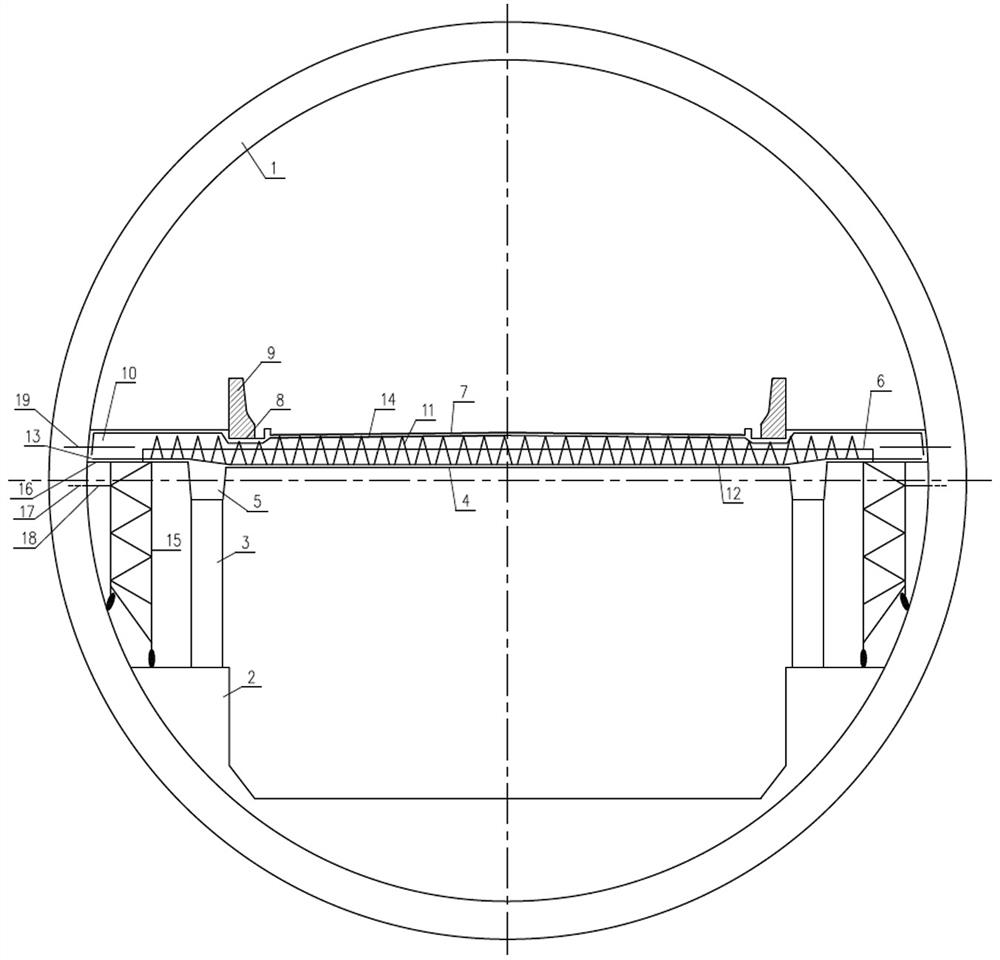

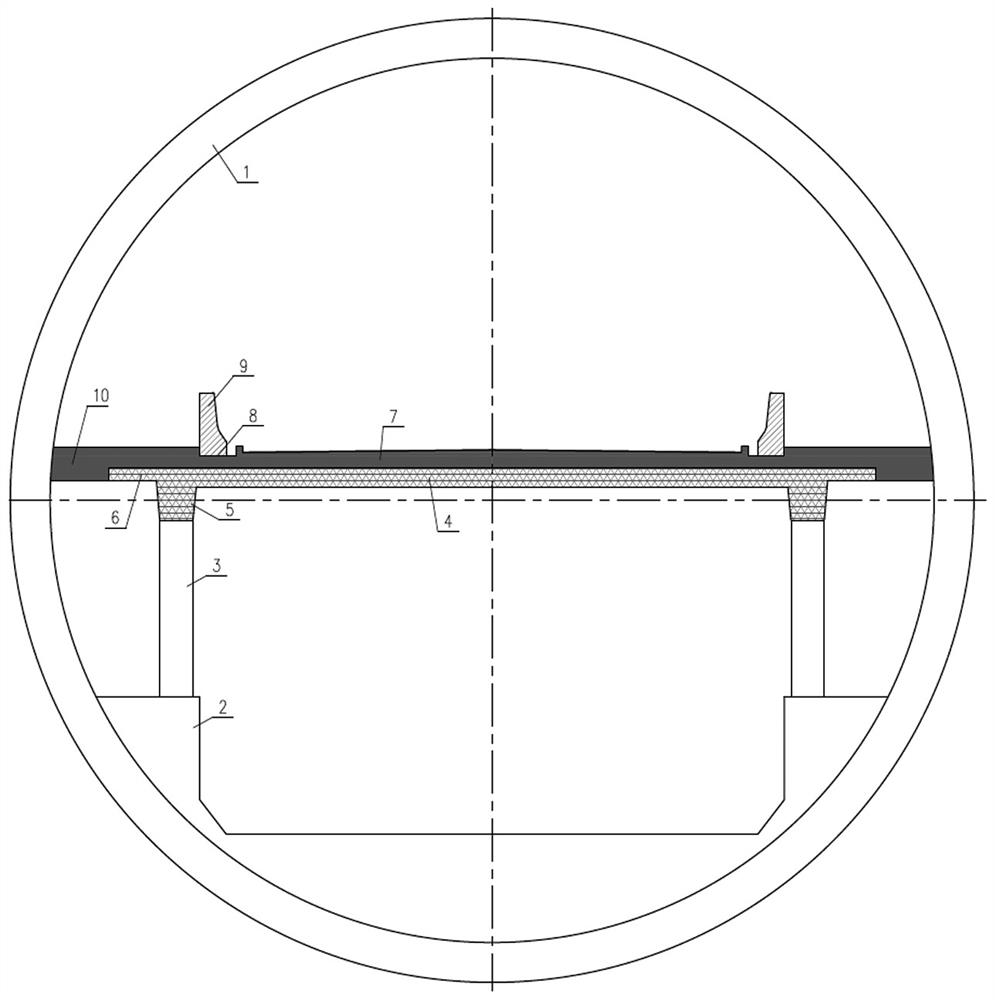

[0021] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

[0022] Described a kind of tunnel prefabricated structure construction method is:

[0023] 1) The embedded nut 17 in the shield tunnel segment 1;

[0024] 2) Assemble segment 1;

[0025] 3) Construction of cast-in-place base 2;

[0026] 4) Assembling prefabricated walls or prefabricated columns 3;

[0027] 5) Lifting and assembling the prefabricated pallet 4, because the width of the prefabricated pallet 4 is greater than the net distance of the base 2, wall or column 3 in the tunnel, the transportation of the pallet 4 needs to be transported longitudinally along the long side of the tunnel, and it is hoisted to the prefabricated pallet 4 by a lifting device. After the 90° rotation is completed on the top of the wall 3, the feet 5 are installed on the prefabricated wall 3, and the cantilevered thin plates 6 at both ends protrude from the prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com