Pump concrete added with steel slag magnetic separation mud powder and preparation method thereof

A technology for pumping concrete and steel slag magnetic separation, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of reducing the pollution of "three wastes", improving workability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

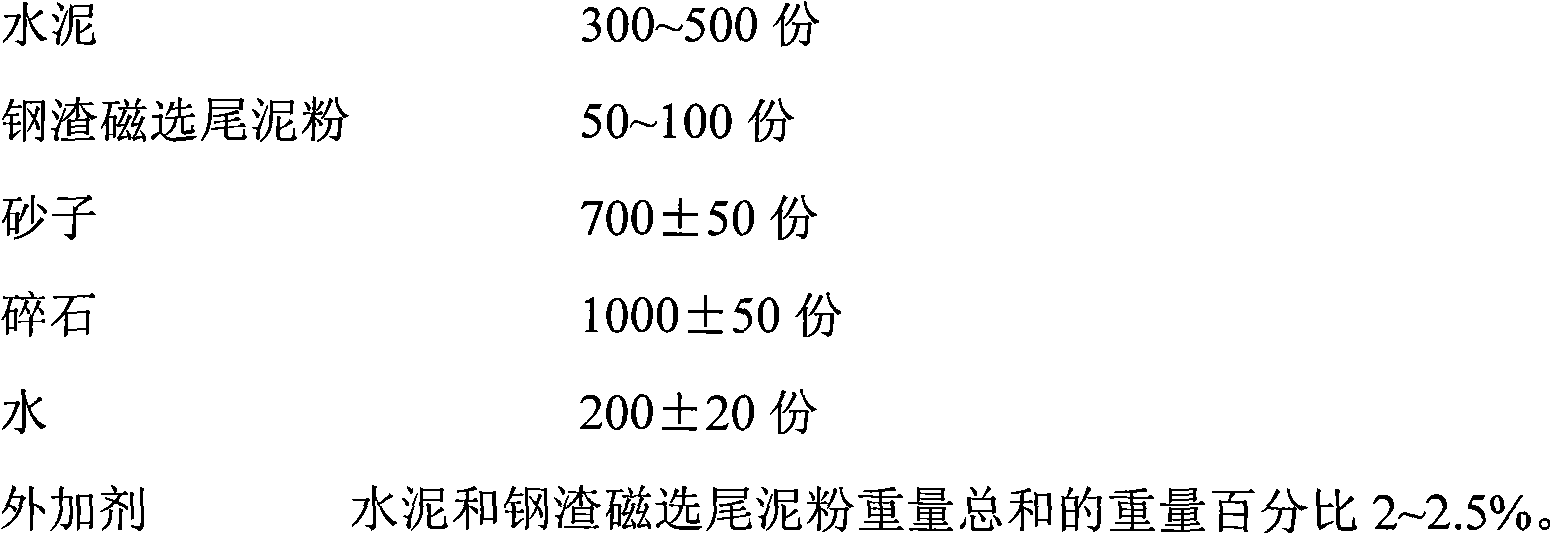

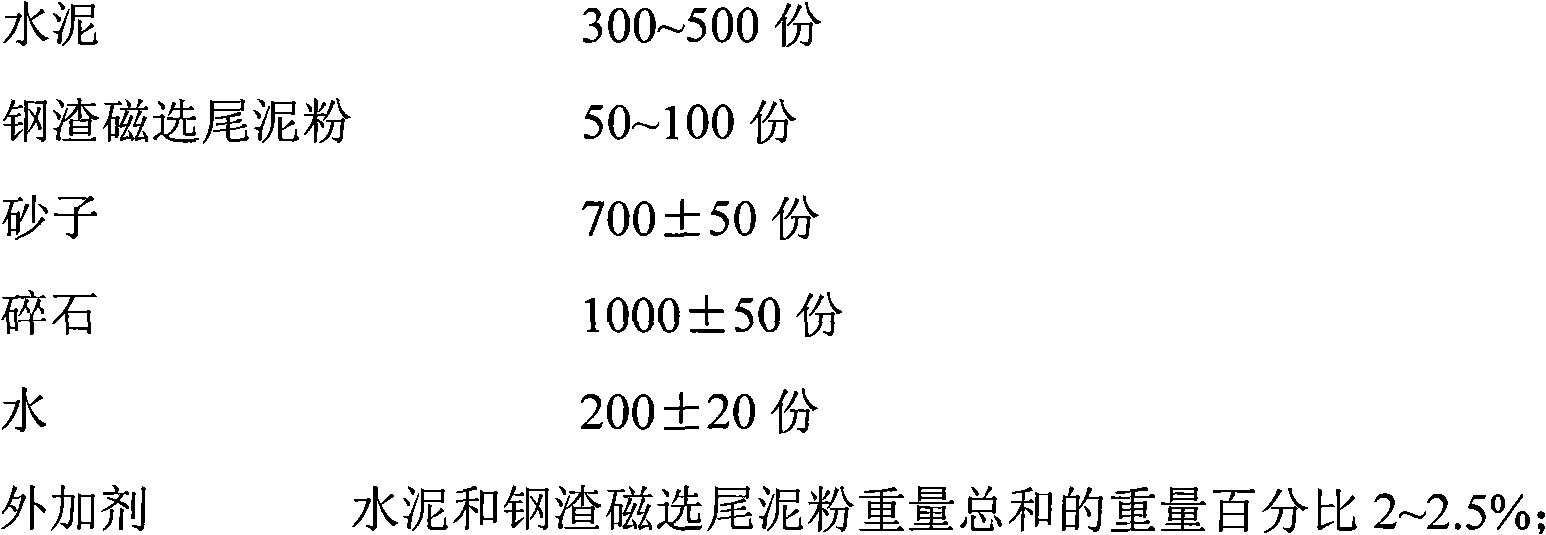

[0021] A pumping concrete added with steel slag magnetic separation tailings powder, made of the following admixtures in proportions by weight:

[0022] Cement: 300 parts; steel slag magnetic separation tailings powder: 50 parts; sand: 740 parts; gravel: 1050 parts; water: 200 parts; admixture: 7 parts.

[0023] According to the aforementioned preparation method, add the cement, steel slag magnetic separation tailings powder, sand, and crushed stone into the mixer according to the weight ratio, and stir and mix; then add water and additives into the forced mixer at the same time, and continue to stir evenly, that is Can be used for construction pouring.

Embodiment 2

[0025] A pumping concrete added with steel slag magnetic separation tailings powder, made of the following admixtures in proportions by weight:

[0026] Cement: 500 parts; steel slag magnetic separation tailings powder: 100 parts; sand: 650 parts; gravel: 950 parts; water: 220 parts; admixture: 15 parts.

[0027] According to the aforementioned preparation method, add the cement, steel slag magnetic separation tailings powder, sand, and crushed stone into the mixer according to the weight ratio, and stir and mix; then add water and additives into the forced mixer at the same time, and continue to stir evenly, that is Can be used for construction pouring.

Embodiment 3

[0029] A pumping concrete added with steel slag magnetic separation tailings powder, made of the following admixtures in proportions by weight:

[0030] Cement: 400 parts; steel slag magnetic separation tailings powder: 75 parts; sand: 700 parts; gravel: 1000 parts; water: 180 parts; admixture: 11 parts.

[0031] According to the aforementioned preparation method, add the cement, steel slag magnetic separation tailings powder, sand, and crushed stone into the mixer according to the weight ratio, and stir and mix; then add water and additives into the forced mixer at the same time, and continue to stir evenly, that is Can be used for construction pouring.

[0032] In the above examples, the cement is slag portland cement grade 32.5; the active ingredient content in the steel slag magnetic separation tailings powder is CaO≥25%, SiO 2 ≥10%, Al 2 o 3 ≥4%, the fineness is 0.045 micron square hole sieve, the sieve residue is less than 20%, or the sieve residue of 0.08 micron squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com