Method for soldering TiAlC ceramic and copper by using Ag-Cu eutectic solder

A technology of ag-cu and brazing material, which is applied in the field of brazing Ti2AlC ceramics and copper, can solve the problems of short life, high cost of current-carrying friction devices, etc., and achieve good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

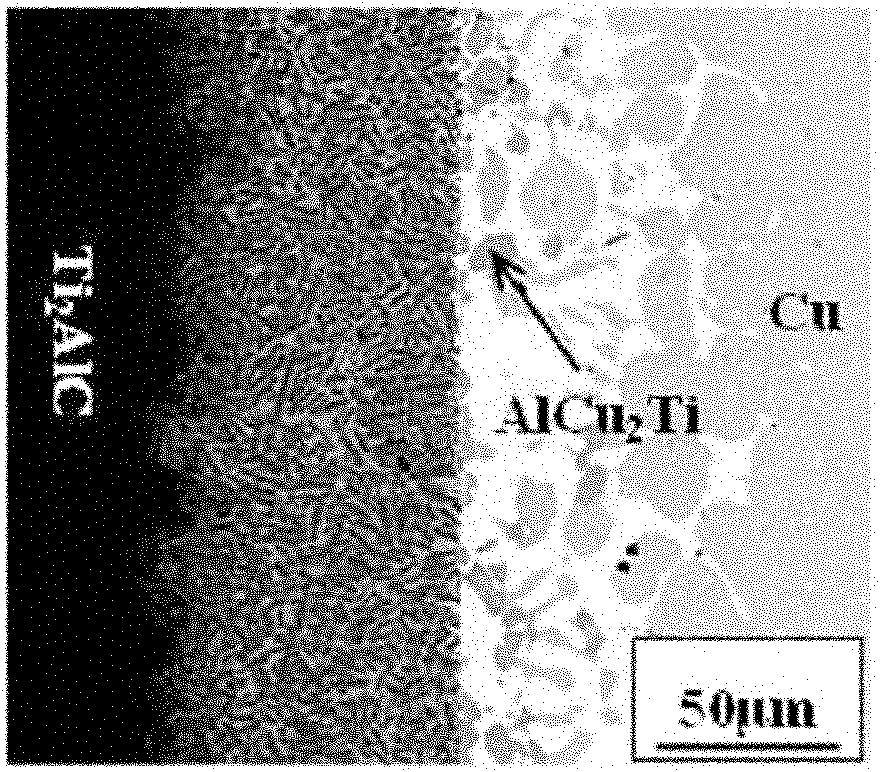

[0013] Specific implementation mode 1: This implementation mode uses Ag-Cu eutectic solder to braze Ti 2 The method of AlC ceramics and copper is realized through the following steps: one, the Ti 2 AlC ceramics were polished to a bright surface with 320#, 600#, 800#, 1000#, 1200# and 1600# metallographic sandpaper in sequence, and then Ti 2 The surface to be connected of AlC ceramics is polished; then the copper is polished to a bright surface with 1000# and 1600# metallographic sandpaper successively, and then the diamond polishing agent of 0.5 μm is used to polish the surface to be connected of the copper; 2. After step 1 Treated Ti 2 Immerse AlC ceramics and copper in absolute ethanol, ultrasonically clean them for 10-20 minutes, take them out, and dry them in the air; 3. Put Ag-Cu eutectic solder, Ti 2 Assembly of AlC ceramic and copper into Ti 2 The structure of AlC ceramics / Ag-Cu eutectic solder / copper is then assembled with a pressure head to obtain a brazing assembl...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that the Ag-Cu eutectic solder described in step 3 is Ag-Cu eutectic powder solder or Ag-Cu eutectic foil. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the Ag-Cu eutectic solder described in step three is Ag-Cu eutectic powder solder, and the preparation method of the brazing assembly is: Cu eutectic powder solder and hydroxyethyl cellulose binder are mixed to obtain paste-like Ag-Cu eutectic solder, and then the paste-like Ag-Cu eutectic solder is coated on Ti 2 The Ag-Cu eutectic solder layer is formed on the surface to be connected of AlC ceramics and the surface to be connected of copper, and then the Ti 2 The Ag-Cu eutectic solder layer on the surface to be connected of AlC ceramics is bonded with the Ag-Cu eutectic solder layer on the surface to be connected of copper, and assembled into Ti 2 The structure of AlC ceramic / Ag-Cu eutectic solder / copper is then assembled with an indenter to obtain a brazed assembly. Other steps and parameters are the same as those in Embodiment 1.

[0019] In this embodiment, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com