Preparation method of exfoliated montmorillonite-epoxy resin composite

A technology of epoxy resin and composite materials, which is applied in the direction of fibrous filler, dyed low-molecular organic compound treatment, dyed high-molecular organic compound treatment, etc. It can solve the problems of adding epoxy resin molecules, difficult to achieve, and increase, and achieve easy Get, promote the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

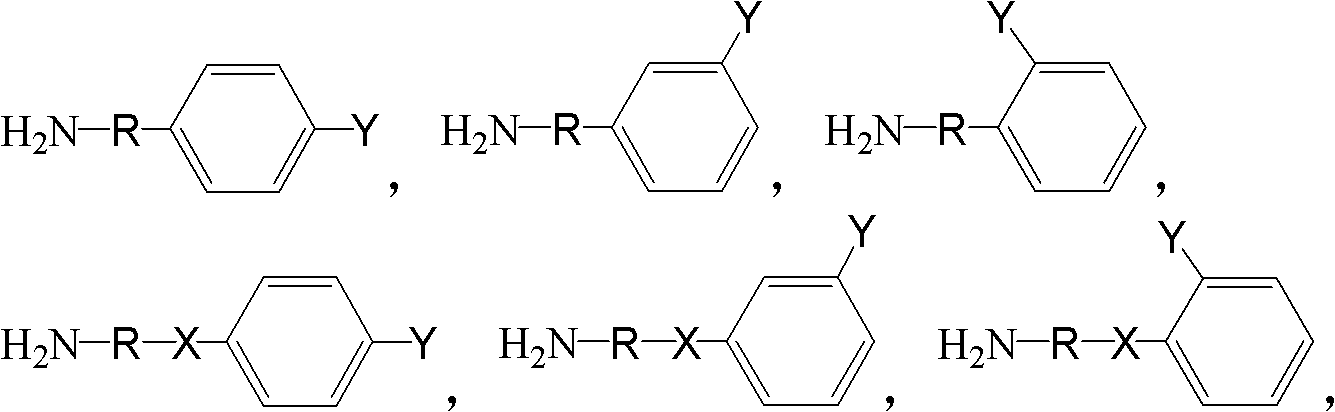

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of preparation method of exfoliation type montmorillonite and epoxy resin composite material comprises the following processing steps:

[0036] (1) Organic modification of montmorillonite:

[0037] a, react according to the ratio of hexamethylenediamine: phenol: formaldehyde molar ratio = 1: 0.9: 0.9 to obtain intercalation agent molecules The obtained intercalation agent and deionized water are mixed according to the weight ratio of 1:10, and a hydrochloric acid solution with a concentration of 5 mol / L is added dropwise until the pH value is between 6 and 7 to obtain an intercalation agent salt solution;

[0038] B, disperse 20g montmorillonite in 500g of ionized water, stir 60min under the condition of stirring speed 500 revs / min, obtain the suspension of montmorillonite, the pH value of described montmorillonite suspension is between 7~ between 8;

[0039]c. The temperature of the montmorillonite suspension is raised to 80° C., adding the inter...

Embodiment 2

[0049] Embodiment 2 A kind of preparation method of exfoliation type montmorillonite and epoxy resin composite material comprises the following processing steps:

[0050] (1) the organic modification of montmorillonite is the same as embodiment 1;

[0051] (2) Mix organically modified montmorillonite with epoxy resin and curing agent to obtain a mixed system:

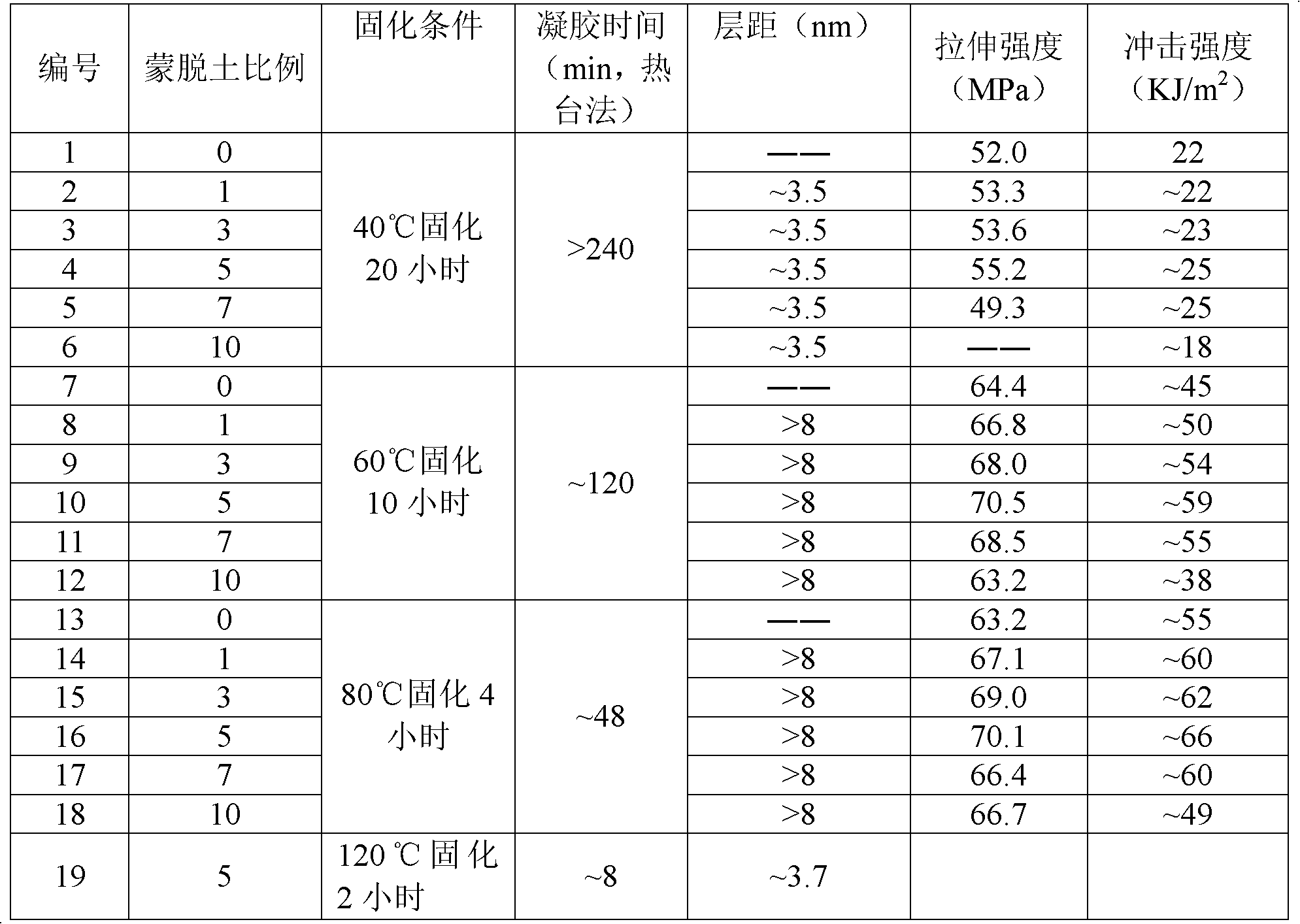

[0052] Under stirring conditions, take m-xylylenediamine 15g, add organically modified montmorillonite 0, 1, 3, 5, 7, 10g, stir for 1 hour and mix evenly, add 100g of epoxy resin E-51, stir for 5 Minute mixing; The stirring speed is 500 rev / min;

[0053] (3) defoaming and curing:

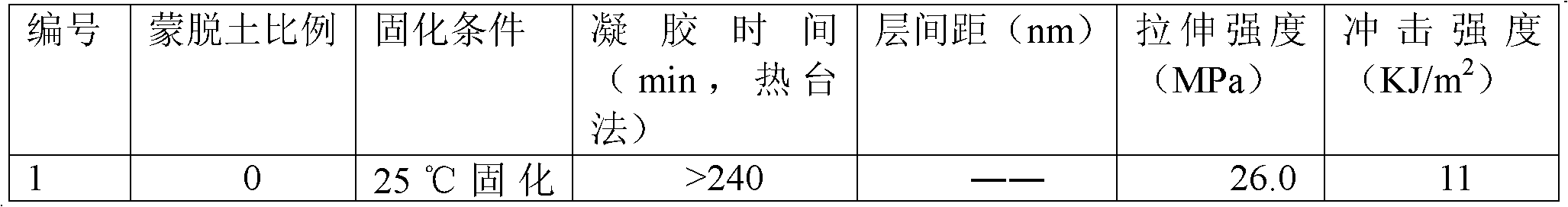

[0054] The mixed system obtained in step (2) is subjected to vacuum defoaming under the condition of vacuum degree of -0.1~-0.09MPa; after the defoaming is completed, the mixed system is poured into the mold and cured according to the following conditions: 25°C for 7 day, cured at 40°C for 16 hours, at 60°C for 8 hours and at 100°C for 2 h...

Embodiment 3

[0060] Embodiment 3 A preparation method of exfoliated montmorillonite and epoxy resin composite material, comprising the following processing steps:

[0061] (1) Organic modification of montmorillonite:

[0062] a, react according to the molar ratio of polyetheramine D-230: phenol: formaldehyde = 1: 0.9: 0.9 to obtain intercalation agent molecules The obtained intercalation agent and deionized water are mixed according to the weight ratio of 1:10, and a hydrochloric acid solution with a concentration of 5 mol / L is added dropwise until the pH value is between 6 and 7 to obtain an intercalation agent salt solution;

[0063] B, disperse 20g montmorillonite in 400g of ionized water, stir 30min under the condition of stirring speed 500 revs / min, obtain the suspension of montmorillonite, the pH value of described montmorillonite suspension is between 7~ between 8;

[0064] c. The temperature of the montmorillonite suspension was raised to 80° C., and an intercalation agent salt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com