Yellow wine rice milk reusing method

A technology of rice milk water and yellow rice wine, applied in chemical instruments and methods, biochemical equipment and methods, applications, etc., can solve problems such as unused discharge of substances, environmental impact of pH, serious environmental pollution, etc., and achieve zero discharge, Effects of protecting the environment and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

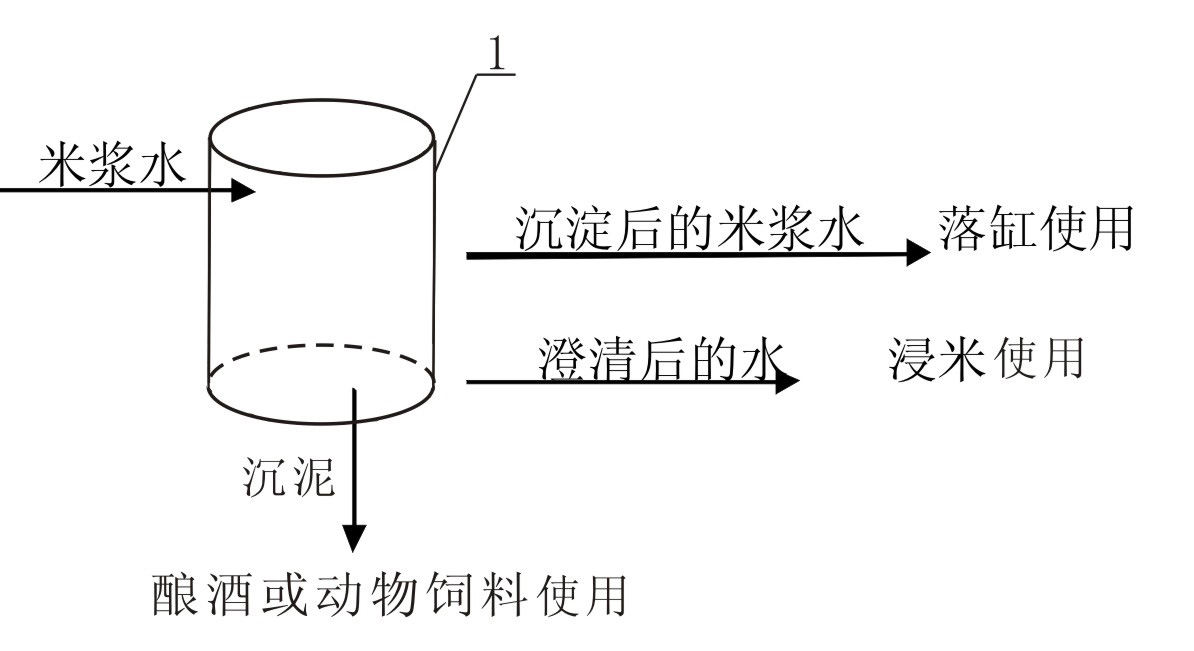

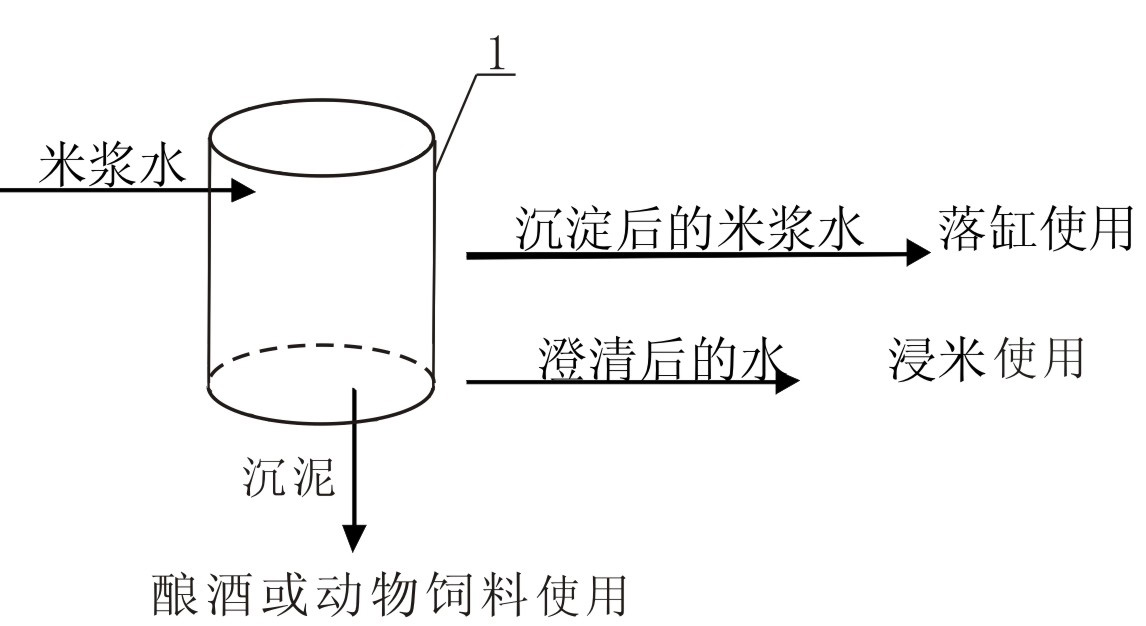

[0015] Such as figure 1 Shown, a kind of rice wine rice milk water reuse method, it may further comprise the steps:

[0016] a, the rice milk water obtained by soaking rice in the rice wine brewing process is imported into the storage tank 1 for storage, and placed for a period of time to allow some sediments to precipitate naturally;

[0017] B, introducing the water after natural precipitation in the storage tank 1 into a container for falling into the tank;

[0018] c. Add flocculant to the unconsumed water of step b in the storage tank 1, and introduce the clarified water after settling into the rice soaking container;

[0019] d. The sediment obtained in step c is drawn out for wine making or animal feed.

[0020] The time for the rice slurry water to be placed in the storage tank 1 in the step a is 36-48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com