Shrinkproof and anti-wrinkle softening agent

A softener and anti-wrinkle technology, applied in the field of textiles, can solve the problems of difficult to control fineness, uniformity, fabric oil spots, oil bleeds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

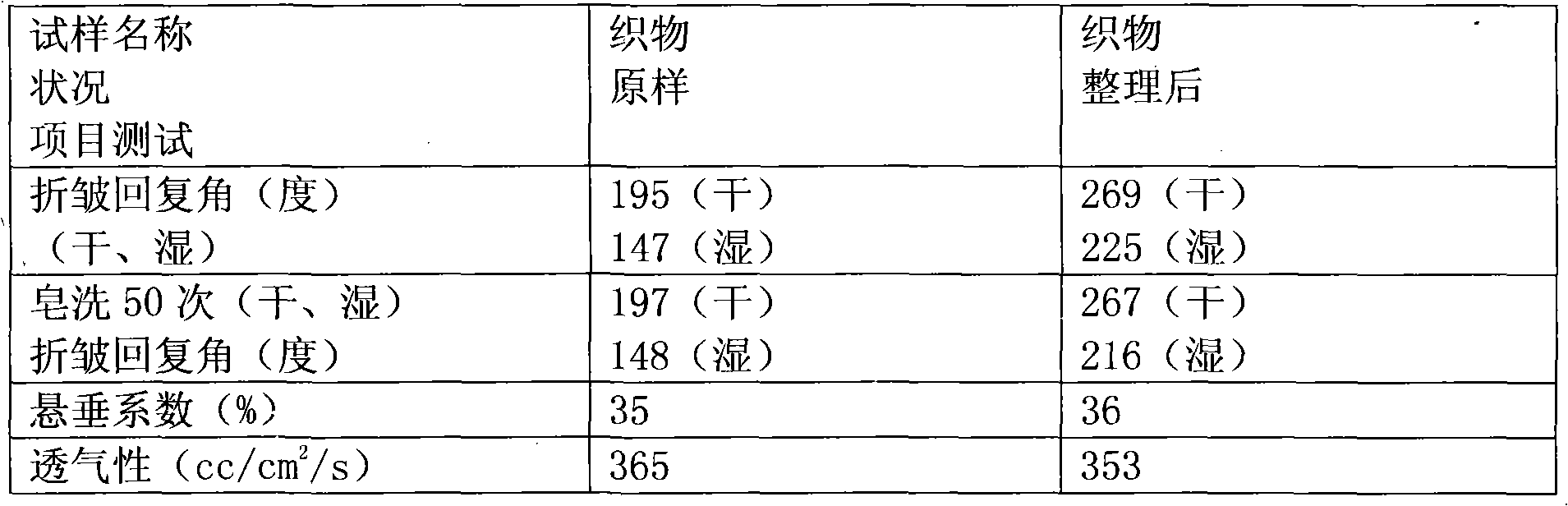

Method used

Image

Examples

Embodiment 1

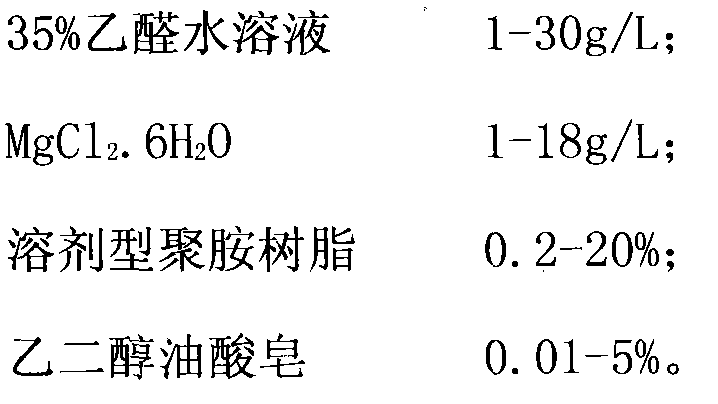

[0026] 35% acetaldehyde aqueous solution 30g / L;

[0027] MgCl 2 .6H 2 O 18g / L;

[0028] Solvent-based polyamine resin 20%;

[0029] Glycol Oleic Soap 5%.

[0030] Preparation:

[0031] First add the above ingredients into the jar and stir to mix, then slowly add the softener dropwise, add 1mol / L MgCl 2 .6H 2 O aqueous solution, stirred to make it into a homogeneous solution, and then configured into a colorless to light yellow aqueous solution according to conventional methods. Using acetic acid to adjust pH=4.5, the solution can be dissolved in water in any proportion.

Embodiment 2

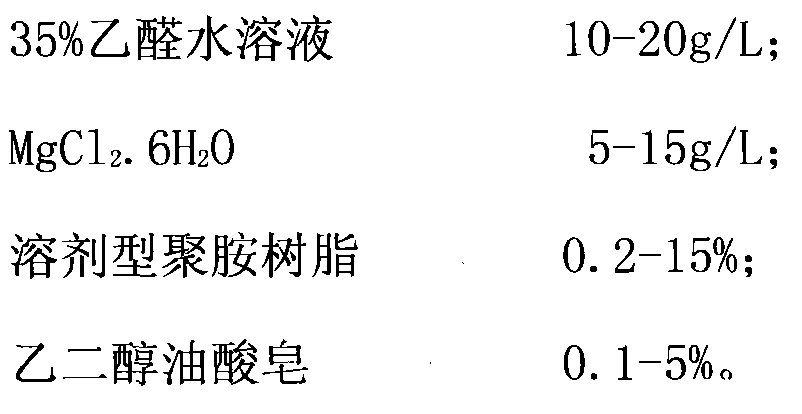

[0033] 35% acetaldehyde aqueous solution 20g / L;

[0034] MgCl 2 .6H 2 O 15g / L;

[0035] Solvent-based polyamine resin 15%;

[0036] Glycol Oleic Soap 5%.

[0037] Preparation:

[0038] First add the above ingredients into the jar and stir to mix, then slowly add the softener dropwise, add 1mol / L MgCl 2 .6H 2 O aqueous solution, stirred to make it into a homogeneous solution, and then configured into a colorless to light yellow aqueous solution according to conventional methods. Using acetic acid to adjust pH=4.5, the solution can be dissolved in water in any proportion.

Embodiment 3

[0040] 35% acetaldehyde aqueous solution 15g / L;

[0041] MgCl 2 .6H 2 O 15g / L;

[0042]Solvent-based polyamine resin 15%;

[0043] Glycol Oleic Soap 5%.

[0044] Preparation:

[0045] First add the above ingredients into the jar and stir to mix, then slowly add the softener dropwise, add 1mol / L MgCl 2 .6H 2 O aqueous solution, stirred to make it into a homogeneous solution, and then configured into a colorless to light yellow aqueous solution according to conventional methods. Using acetic acid to adjust pH=4.5, the solution can be dissolved in water in any proportion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com