Technique for processing geocell

A geocell and processing technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of long processing cycle, many procedures, deformation of geocell, etc., to improve processing efficiency, stable chemical properties, The effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

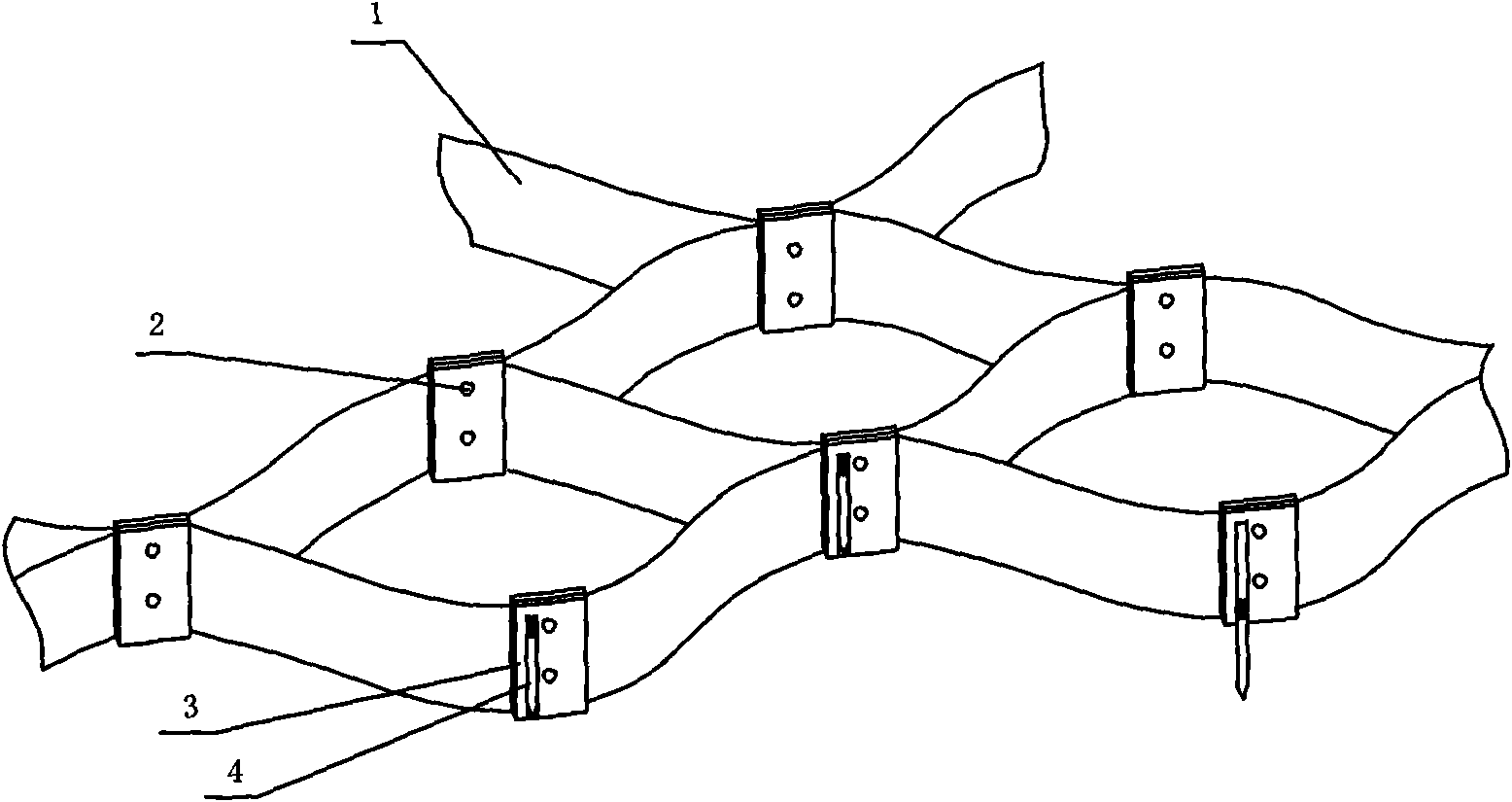

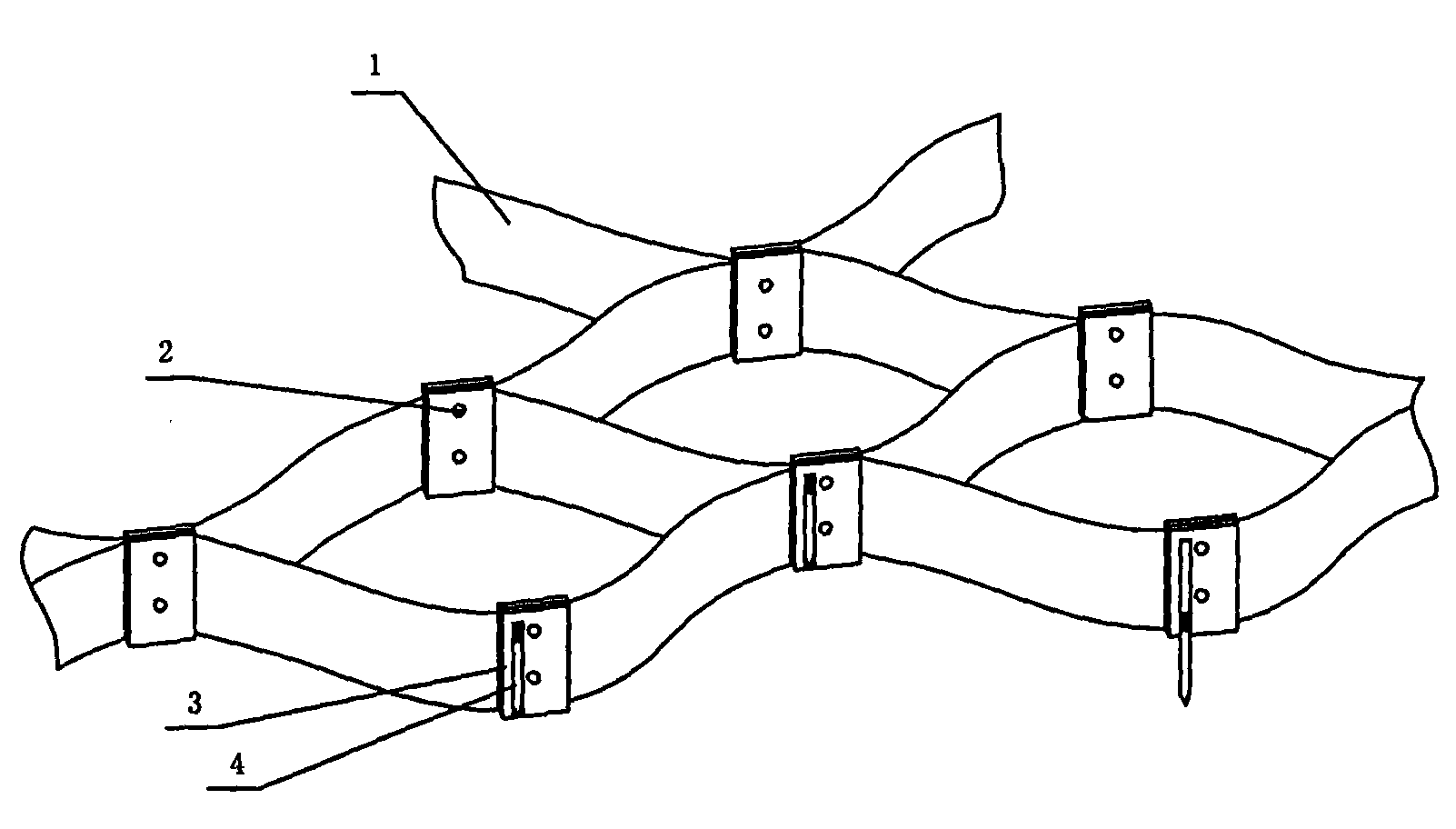

[0010] Such as figure 1 As shown, the present invention first folds the ground strips 1, and then connects the adjacent ground strips 1 at intervals and alternately through several connecting buckles 3; after the connected geocells are stretched transversely, they are honeycomb-shaped, The process of connecting adjacent strips 1 at intervals and interlacedly includes punching holes 2 at the connection parts of adjacent strips 1; An integrated connecting buckle 3 .

[0011] The ground strip 1 is made of nylon material, and the process of mechanical injection molding includes: first clamping the adjacent ground strip 1 with the hole 2 on the mechanical injection molding machine through an injection mold, and heating it to a temperature slightly higher than that of nylon. The melting point of strip 1; then inject molten plastic into the injection mold.

[0012] For ease of use, the connecting buckles 3 of some outer parts in some connecting buckles 3 adopt the connecting buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com