Engine room for wind generating set

A technology for wind turbines and nacelles, which is applied to wind turbine components, wind engines, and wind power generation. It can solve problems such as damage, difficulty in installation, and weak mechanical connection strength, and achieve normal operation, easy installation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

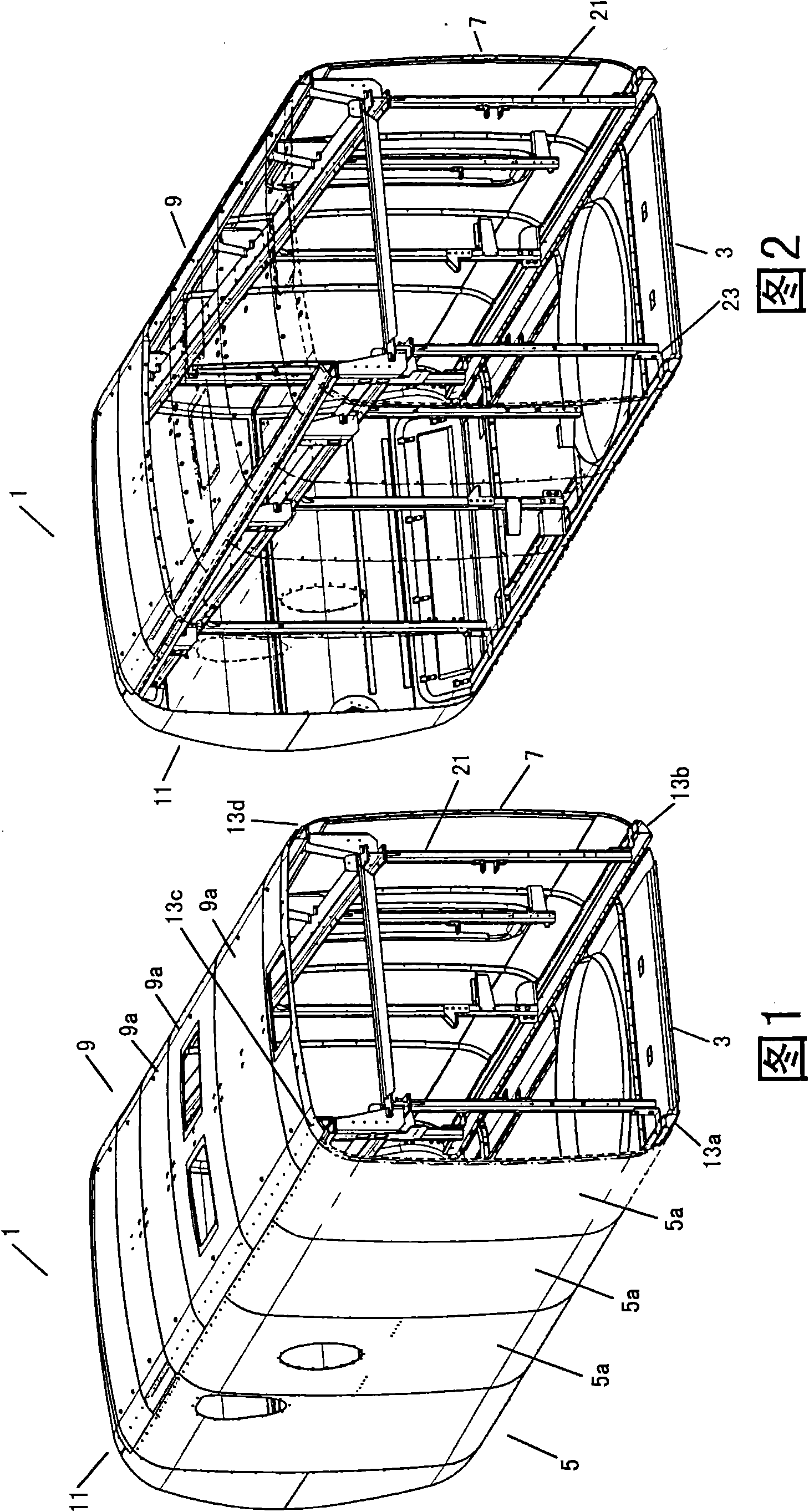

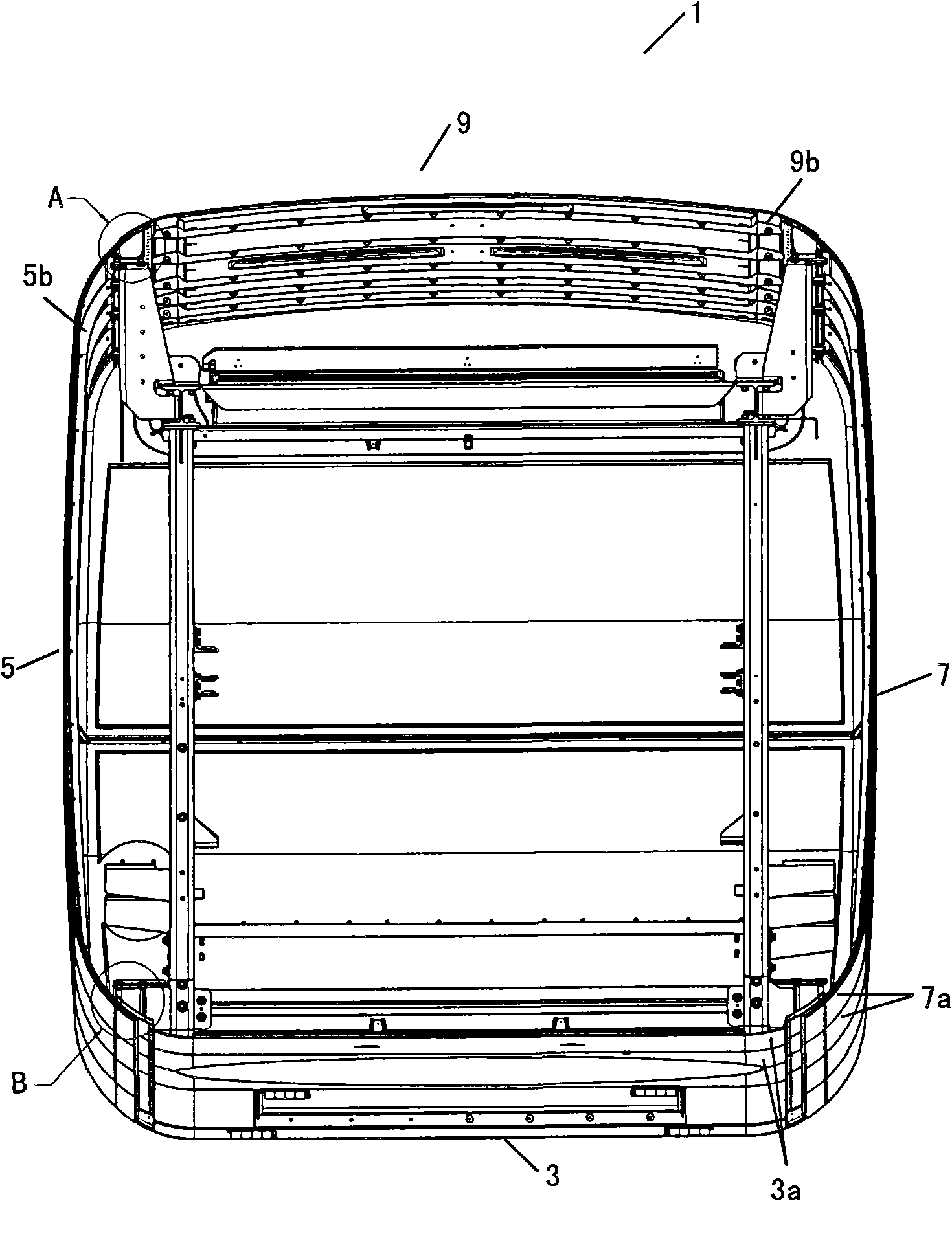

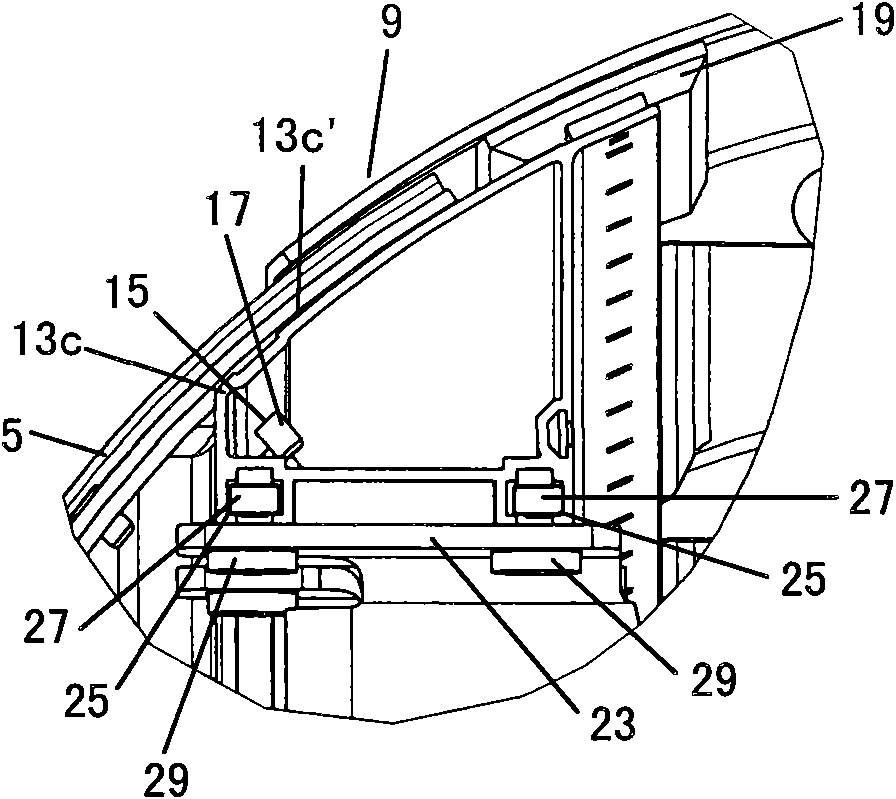

[0038] The nacelle 1 for a wind power generating set according to the present invention will be described in detail below with reference to the accompanying drawings. The nacelle 1 according to the invention comprises a bottom wall 3 , a first side wall 5 , a second side wall 7 opposite to the first side wall 5 , and a top wall 9 . The nacelle 1 according to the invention also comprises a rear end cover or rear end wall 11 and a not shown front end cover or front wall. These walls are interconnected to form a generally hexahedron-shaped space. Of course, openings may be formed at corresponding positions on the wall of the nacelle 1 according to the installation requirements of other components of the wind power generating set. It should be understood that the nacelle 1 according to the invention may be formed in any other suitable shape than the illustrated hexahedral shape, such as a pentahedral shape or an elliptical cylindrical shape.

[0039] According to the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com