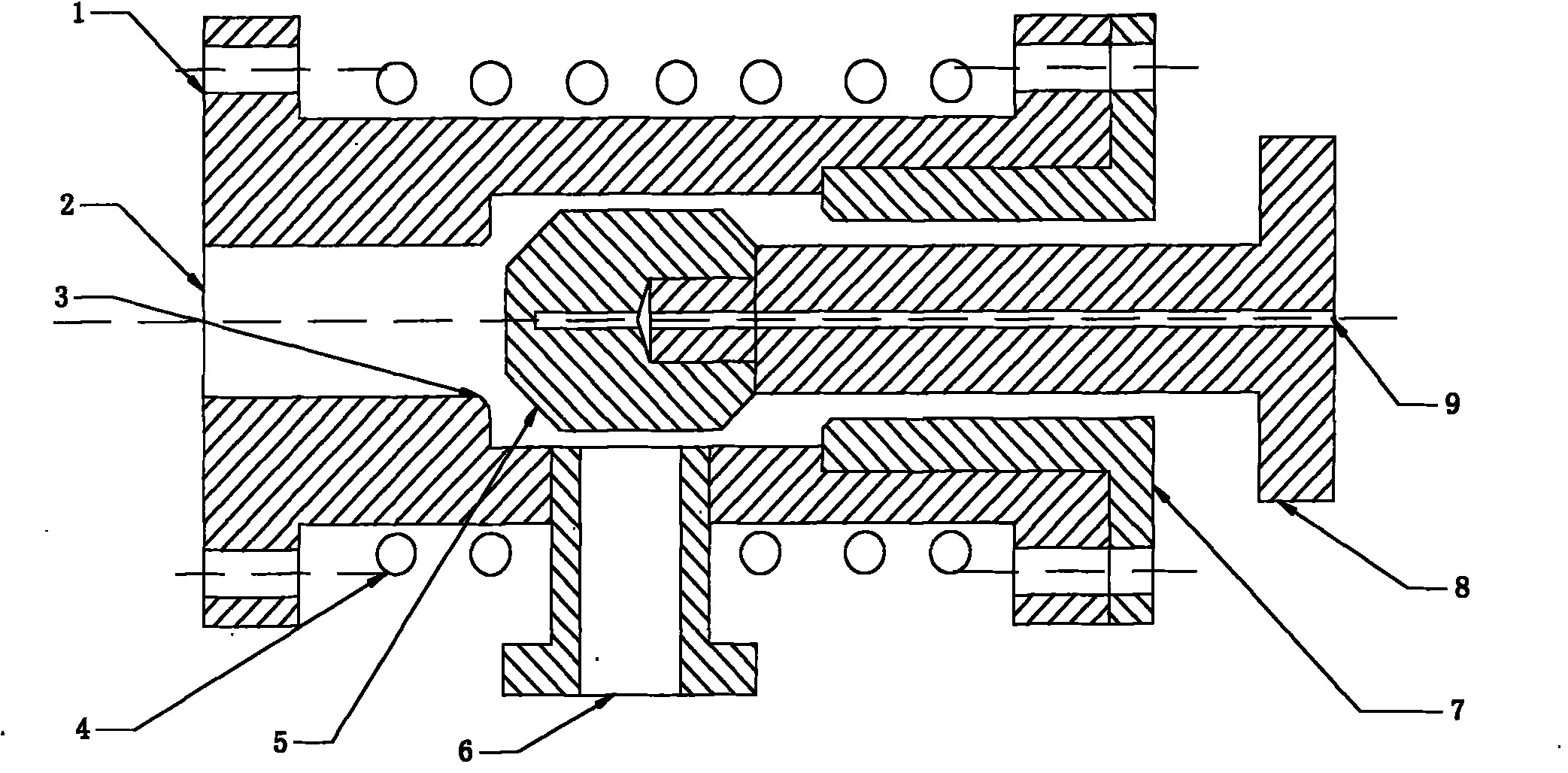

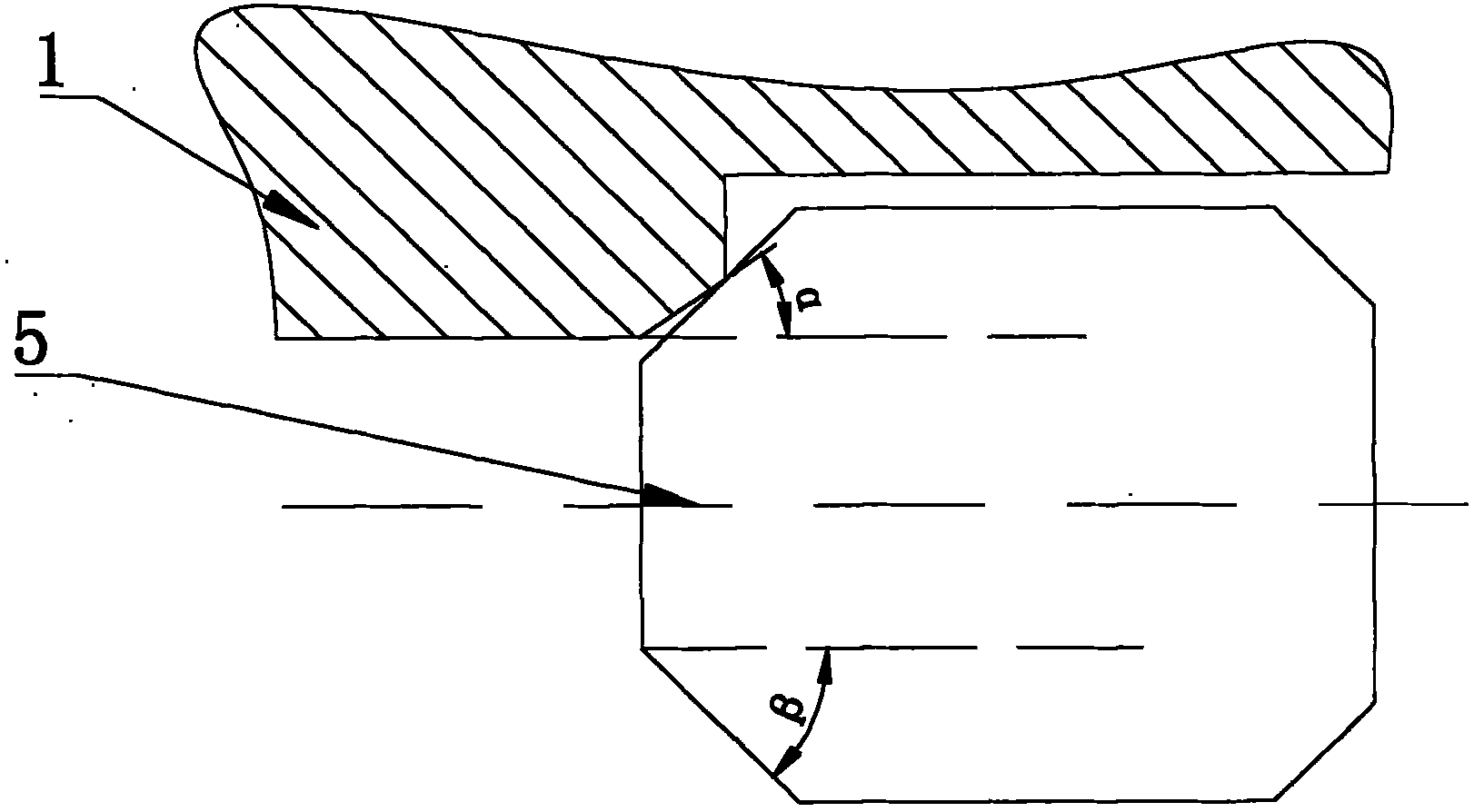

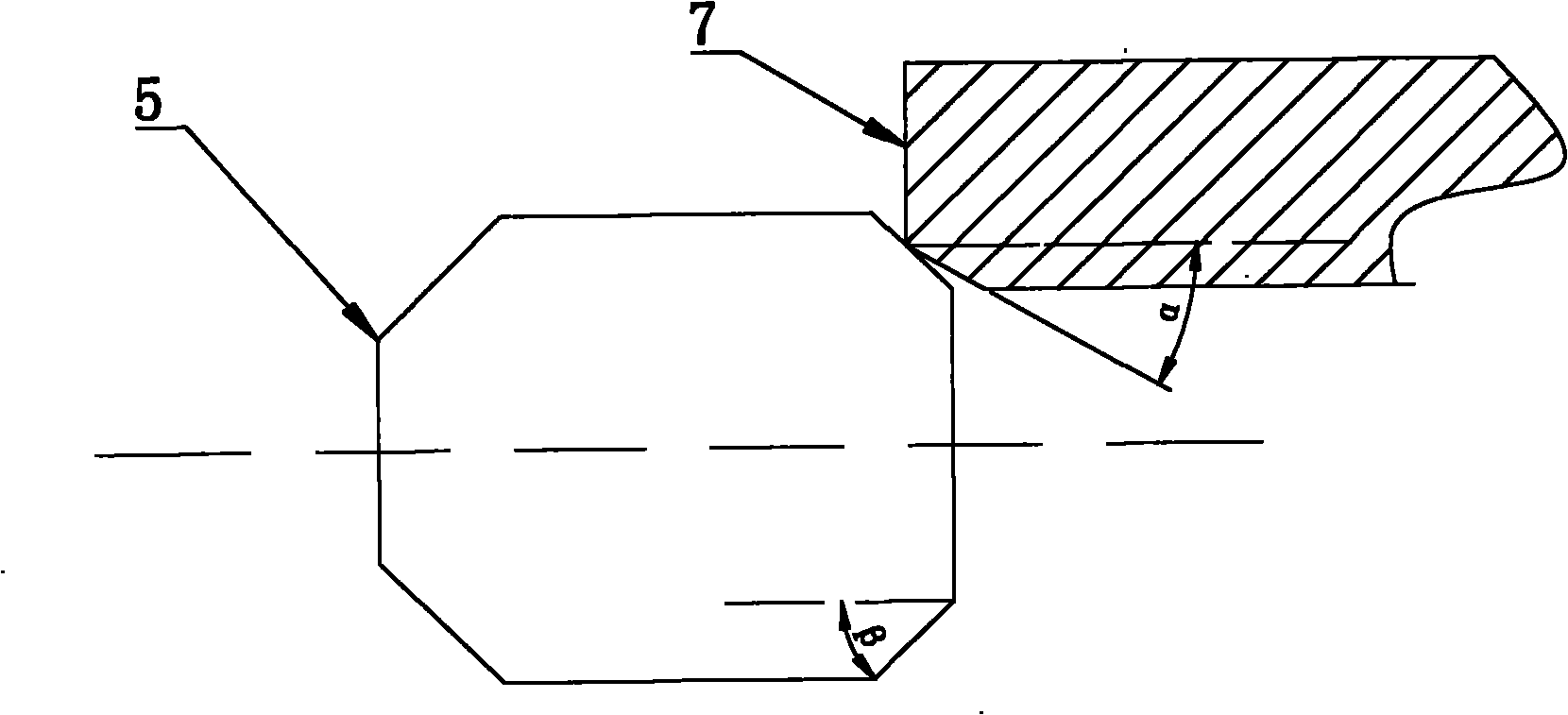

Valve for controlling delivery of metal melt and use method thereof

A metal melt and valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of high surface tension, valve failure, melt blockage, etc., to achieve simple and convenient control, avoid valve stem stuck, disassemble Easy to install and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment: Using a valve body to control magnesium alloy melt processing equipment

[0028] The magnesium alloy melt processing device performs shearing and stirring treatment on the magnesium alloy melt at 600°C, connects the melt inlet port of the valve body with the melt outlet of the magnesium alloy melt processing equipment, and connects the valve stem with the external pneumatic drive device , The valve body heater heats the valve core to a temperature of 600°C. The pneumatic drive device drives the spool to close the melt inflow port. After the magnesium alloy melt is stirred, the pneumatic drive device drives the valve core to close the valve socket, and the magnesium alloy melt flows out from the melt outflow port into the subsequent forming mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com