Composite micro wind turbine generator

A kind of wind power generator, composite technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electromechanical device, etc., can solve the problem of low generator output power, low conversion efficiency, It cannot meet the piezoelectric requirements of wireless sensor network nodes and other problems, and achieve the effect of increasing output power, simple structure, and convenient batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

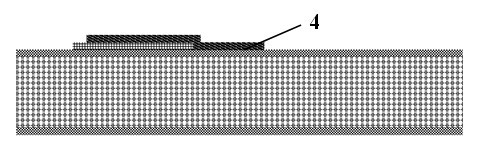

[0025] At the same time, based on the principle of piezoelectric effect and electromagnetic induction, the composite micro-wind generator that realizes electromechanical conversion is composed of micro-stents, micro-beams, piezoelectric structures, metal coils, permanent magnets and bases. The micro-beams are fixed on the micro-stents, and the piezoelectric The structure and metal coils are processed on the micro-beams, and the permanent magnets are fixed on the base. The following is a typical process for making a composite micro-wind turbine:

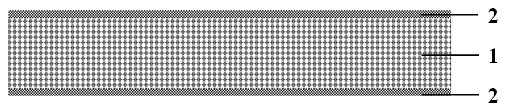

[0026] 1. Select a double-sided polished silicon wafer as the substrate 1, and grow S on the front and back of the substrate 1 simultaneously by oxidation or low-pressure chemical vapor deposition i o 2 Layer 2, such as figure 1 shown;

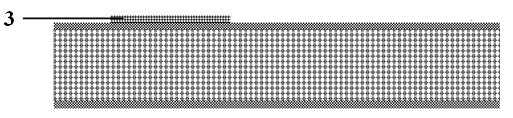

[0027] 2. Deposit Ti and Pt layers sequentially on the front side of the silicon wafer by magnetron sputtering, then apply photoresist, and perform photolithography once to form a photoresist patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com