Heat dissipating device

A technology of heat dissipation device and heat pipe, which is applied to indirect heat exchangers, heat exchange equipment, heat exchanger fixing and other directions, can solve the problems of loose buckle fastening, increased material cost and manufacturing cost, short circuit of circuit board, etc. Eliminates risk of board shorts and reduces assembly and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

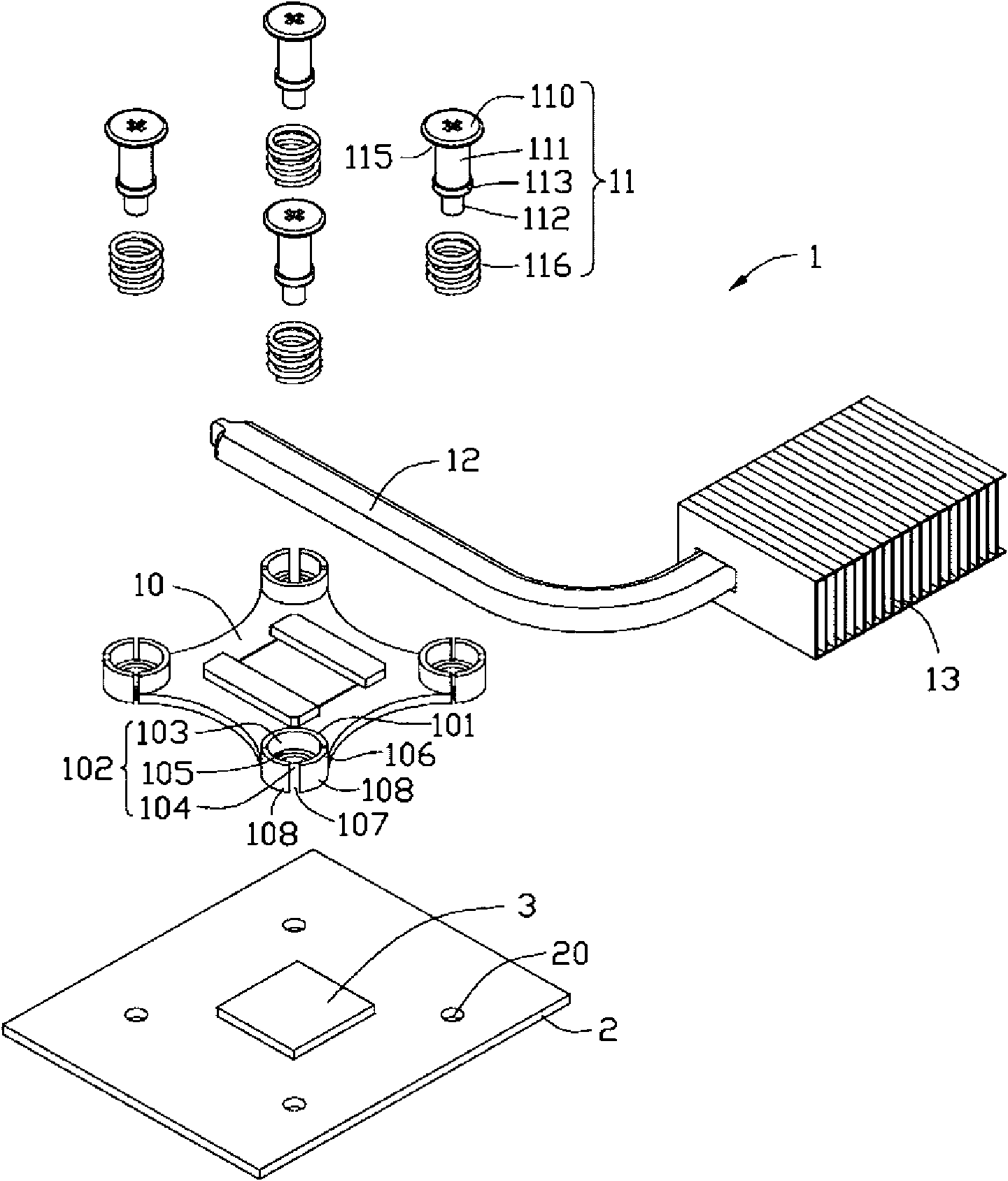

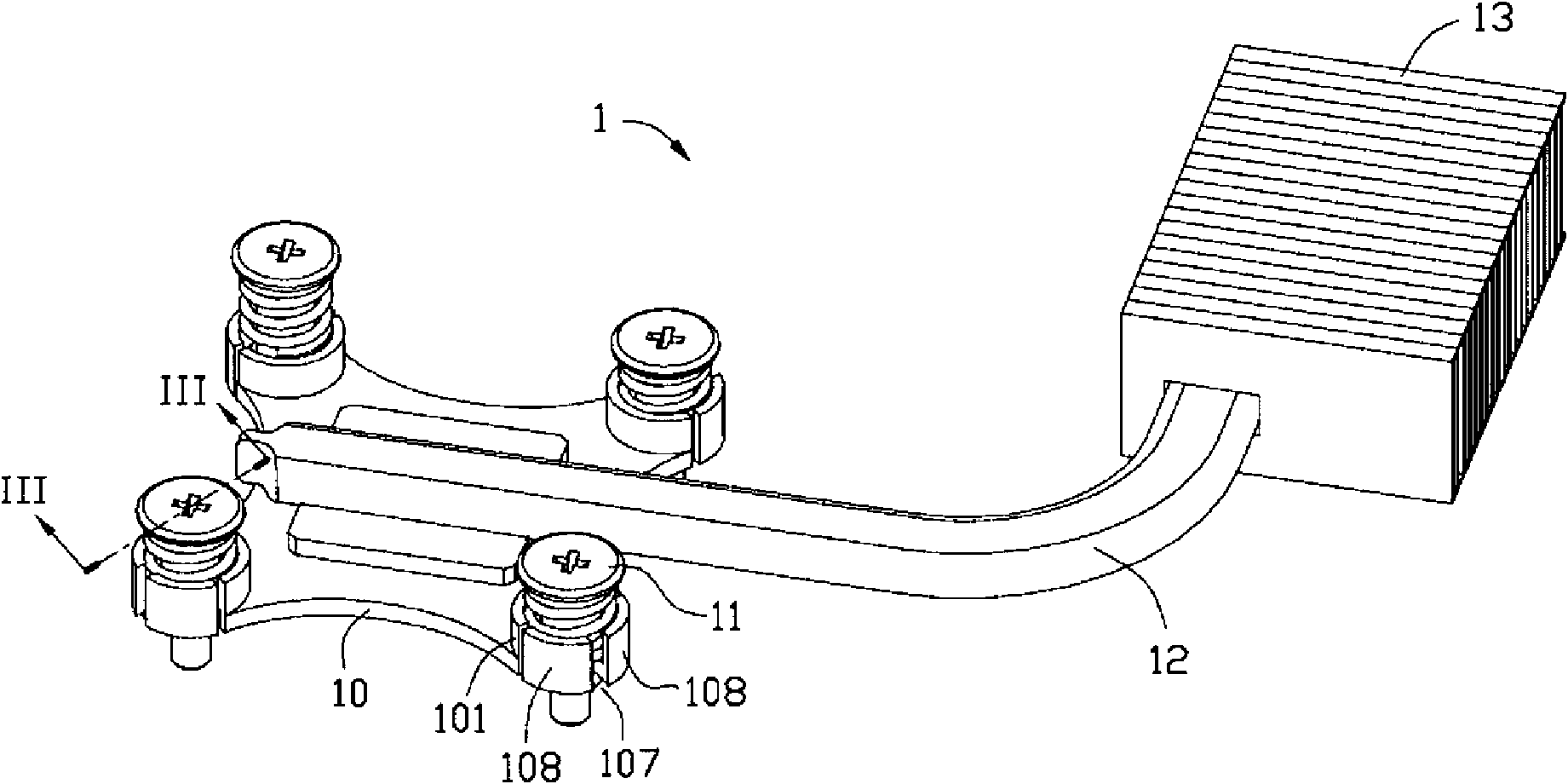

[0010] The heat dissipation device 1 will be further described below with reference to the accompanying drawings. Such as figure 1 As shown, the heat dissipation device 1 includes a base 10 , a plurality of spring fasteners 11 , a heat pipe 12 and a heat sink set 13 . One end of the heat pipe 12 is laid on the upper surface of the base 10 , and the other end passes through the heat sink assembly 13 . The heating electronic components 3 on the circuit board 2 are attached to the lower surface of the base 10 . The base 10 absorbs the heat emitted by the heating electronic components 3 , and the heat pipe 12 transfers the heat from the base 10 to the heat sink group 13 to be dissipated into the air.

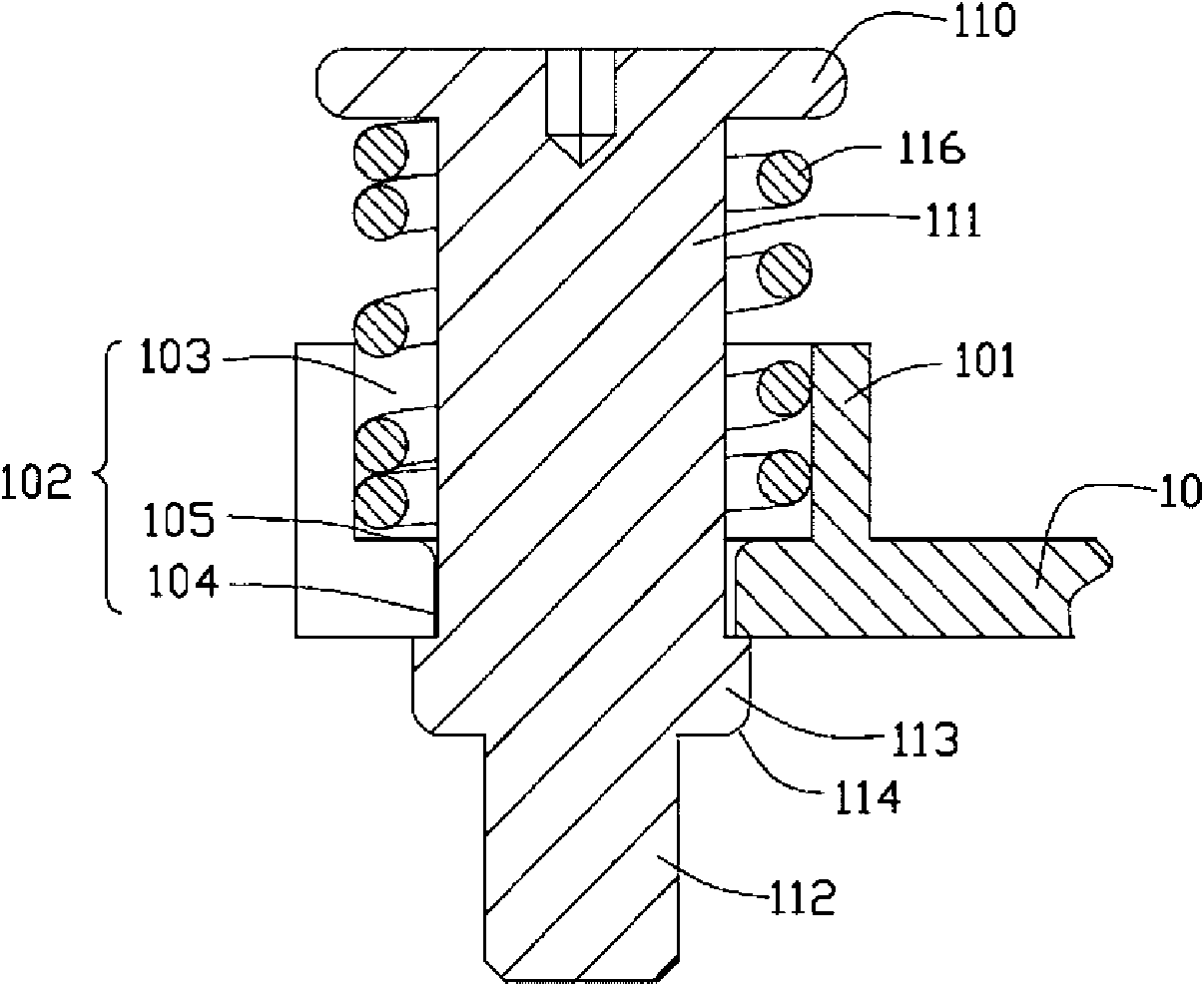

[0011] Please also refer to figure 2 image 3 In this embodiment, the spring fastener 11 is a spring screw. The spring fastener 11 includes a head 110 , a rod body 111 and a spring 116 . The bottom end of the rod body 111 is provided with a thread 112 . The thread 112 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com