Gas barrier coatings

A coating and gas barrier technology, used in coating, thin material processing, synthetic resin layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

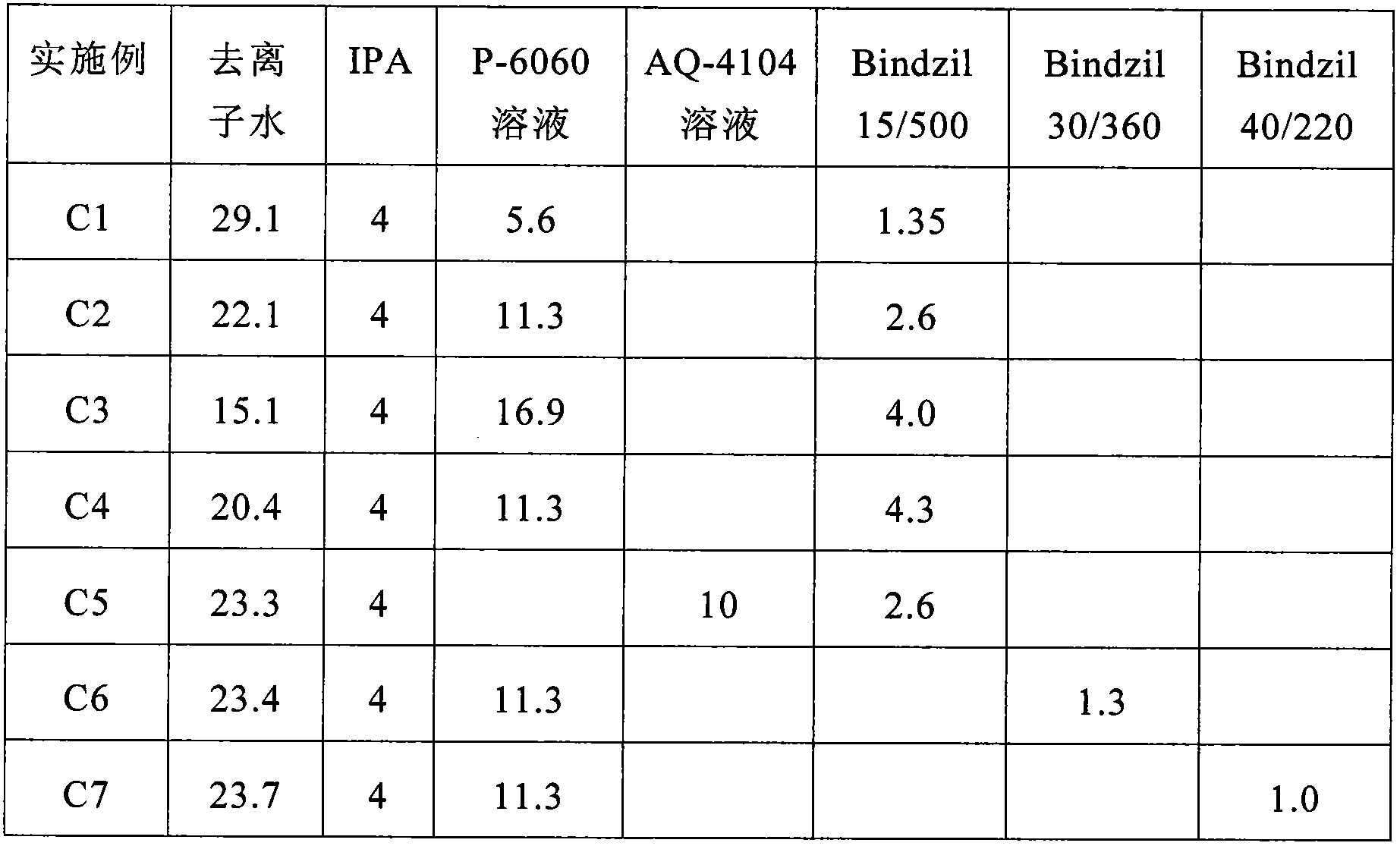

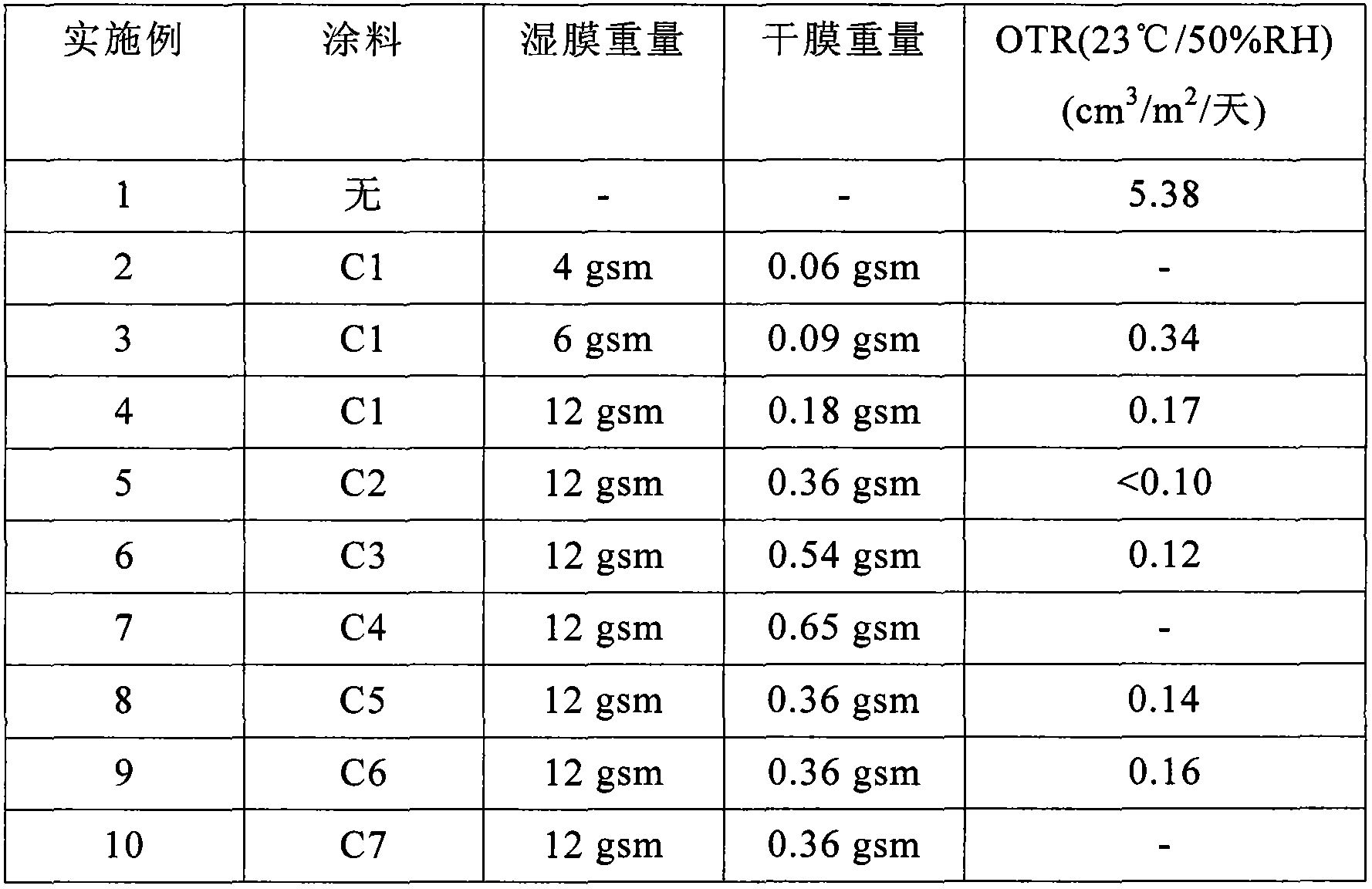

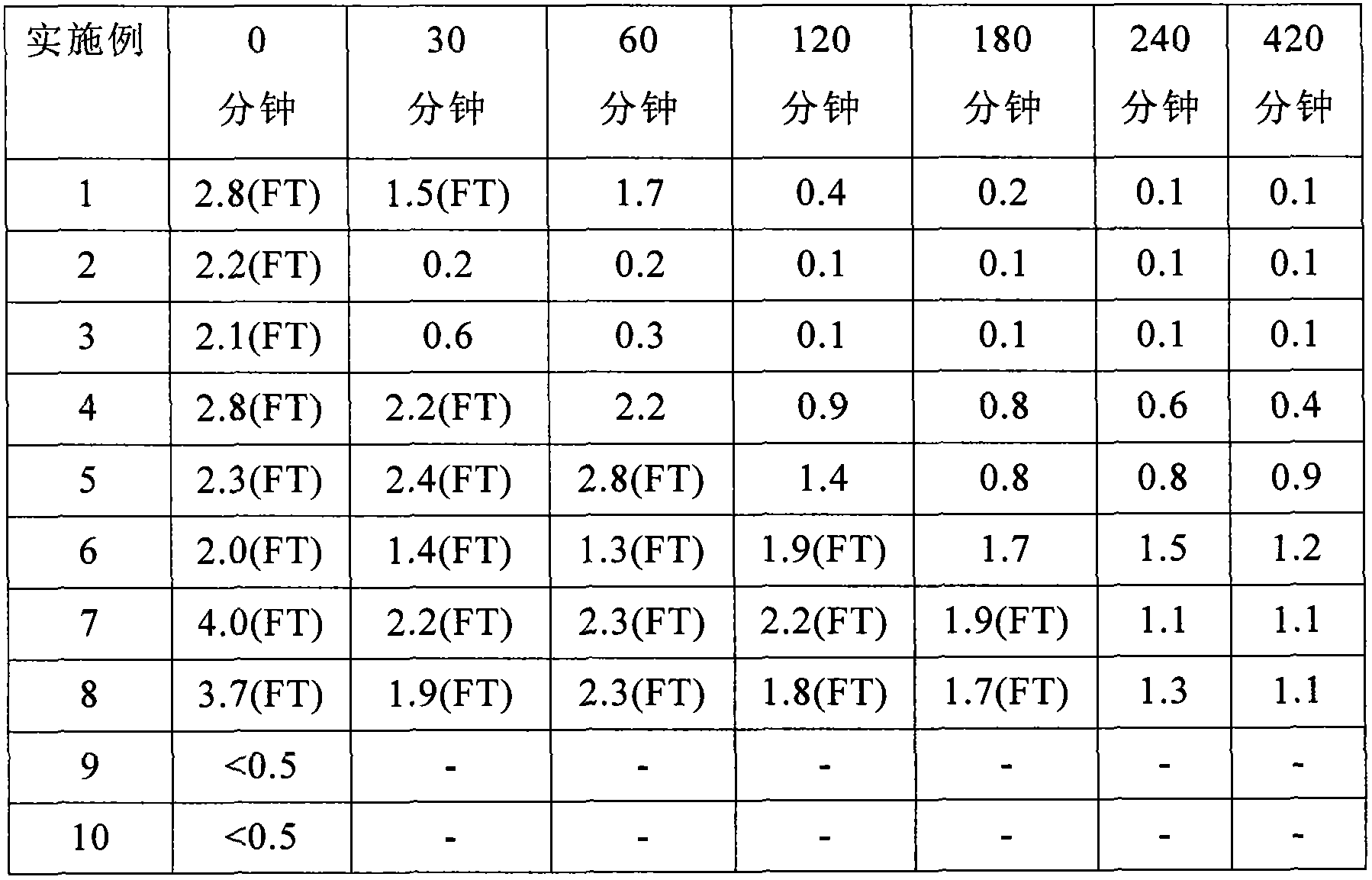

[0038] The starting materials used to prepare these examples were:

[0039] 1. For example polyviol P-6060 from Wacker, a 7.1% (w / w) aqueous solution of silylated polyvinyl alcohol;

[0040] 2. An 8.0% (w / w) solution of Exceval AQ-4104 in a 90 / 10 blend of water / IPA, a water-soluble ethylene / vinyl alcohol copolymer;

[0041] 3. Bindzil 15 / 500, eg EKA. The anionic colloidal silica has a solid content of 15% and a specific surface area of 500m 2 / g, the required particle size range is 3-5nm, and the measured average particle size is about 10nm;

[0042] 4. Bindzil 30 / 360, eg EKA. The anionic colloidal silica has a solid content of 30% and a specific surface area of 360m 2 / g, the required particle size range is 8-20nm, and the average particle size is about 20nm;

[0043] 5. Bindzil 40 / 220, eg EKA. The anionic colloidal silica has a solid content of 40% and a specific surface area of 220m 2 / g, the required particle size range is 7-25nm, and the average particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com