Transmission device comprising a transmission housing

A transmission and casing technology, applied in the field of transmission devices, can solve problems such as large construction space requirements, and achieve cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

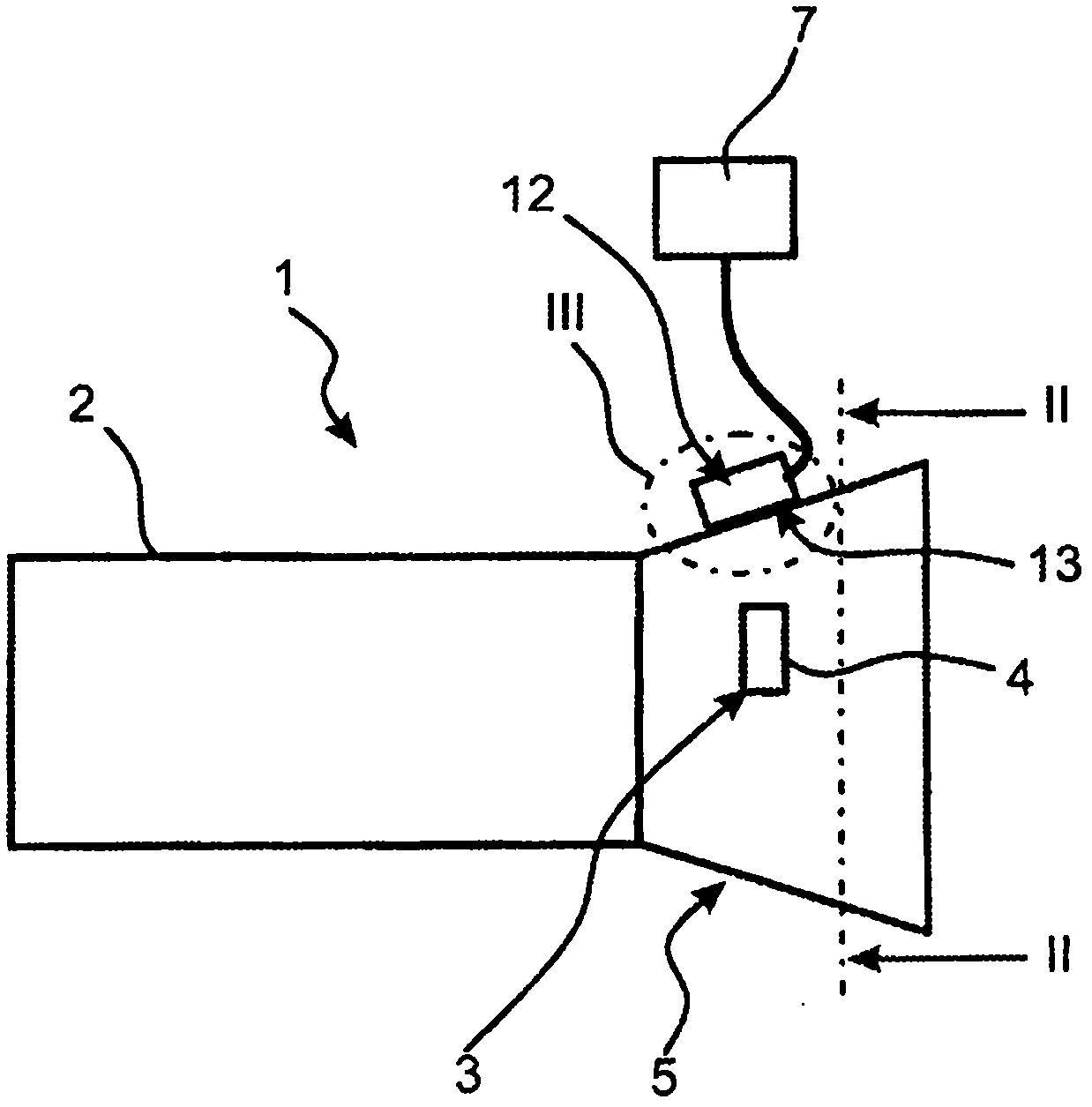

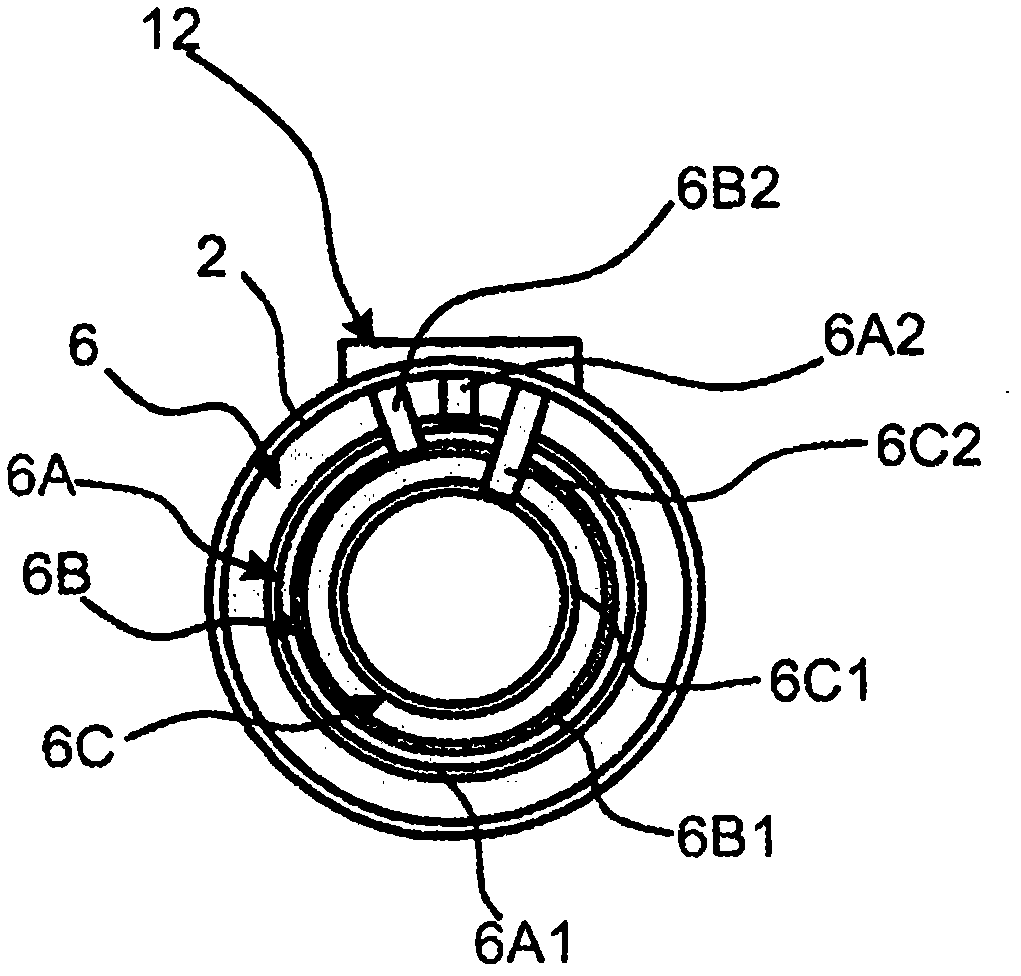

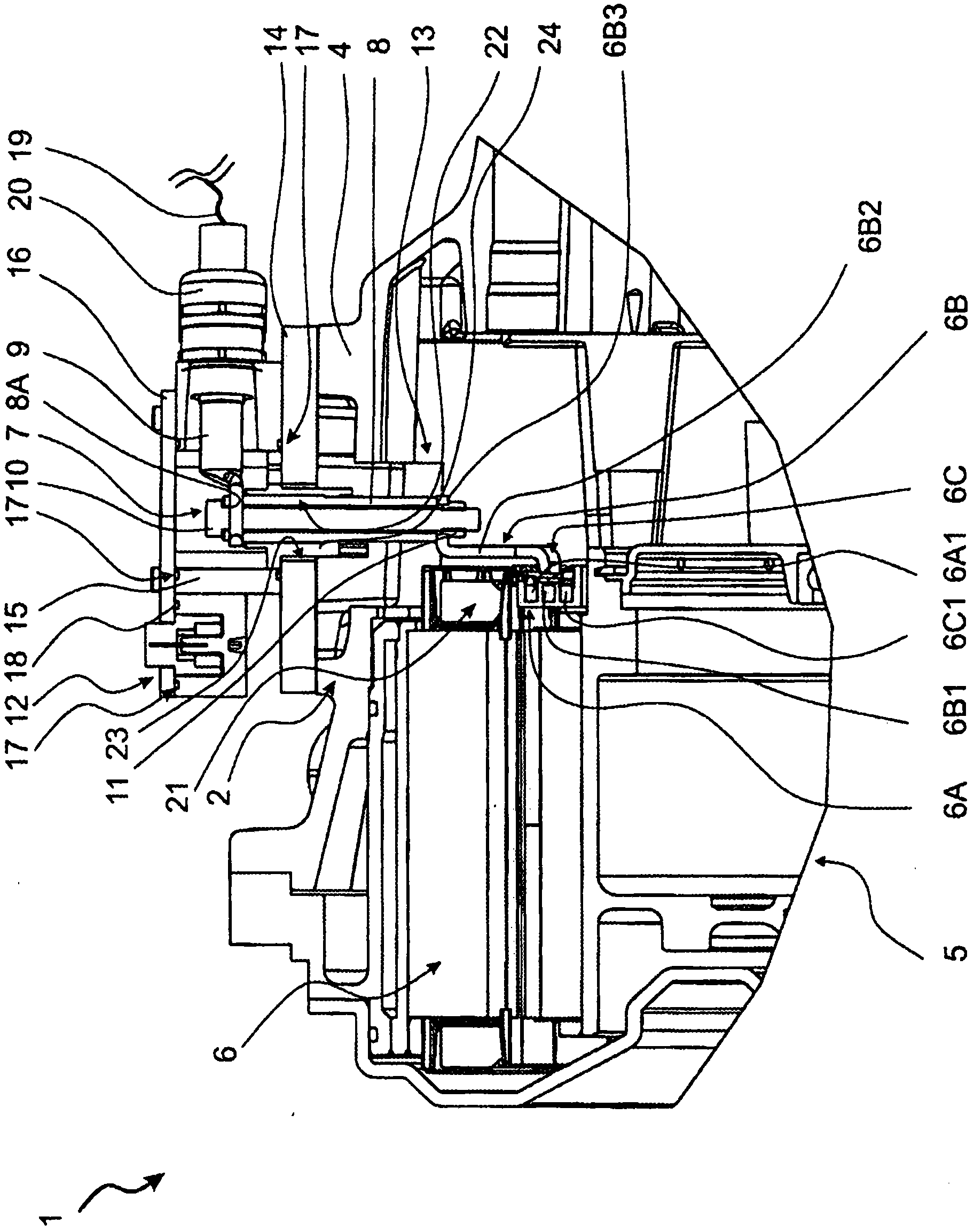

[0015] figure 1 Shows a very schematic illustration of a transmission device 1 according to the invention, which contains a transmission housing 2 in which a number of different gears not shown in detail in the drawings can be arranged for obtaining a number of different gears. The component group of the transmission ratio and a starting device in the form of a torque converter. A plurality of through-holes 3 , 13 can be provided in a wall region of the transmission housing 2 , the edge region 4 of which is formed as a reinforcement zone and through which torque can be conducted from the transmission housing 2 to a formed The transmission device 1 is a power output device of a vehicle provided outside a transmission case.

[0016] The through-holes 3 are correspondingly provided in a known manner during a suitable casting production process, preferably during a die-casting production process, so that the wall region of the transmission housing 2 surrounded by the edge region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com