Optical sheet, light-emitting device, and method for manufacturing optical sheet

A light-emitting device and manufacturing method technology, applied in the direction of electroluminescence light source, optics, optical components, etc., can solve the problems of raising the cost of the product, failing to guarantee the light extraction efficiency, exceeding the critical angle, etc., achieving a simple structure and suppressing the light intensity The distribution and color imbalance, the effect of improving the light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

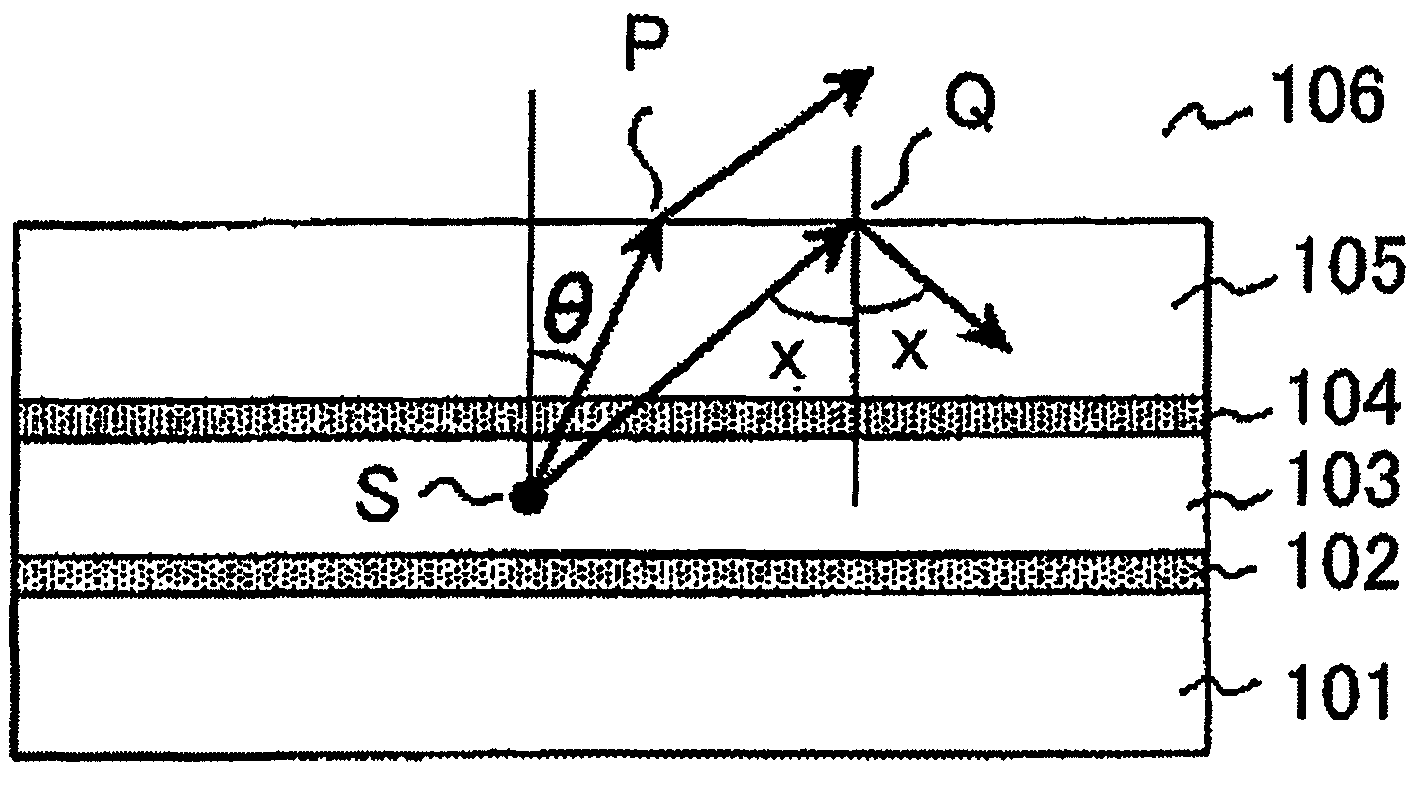

[0102] based on Figures 12-19 , Figure 27 , to describe the first embodiment.

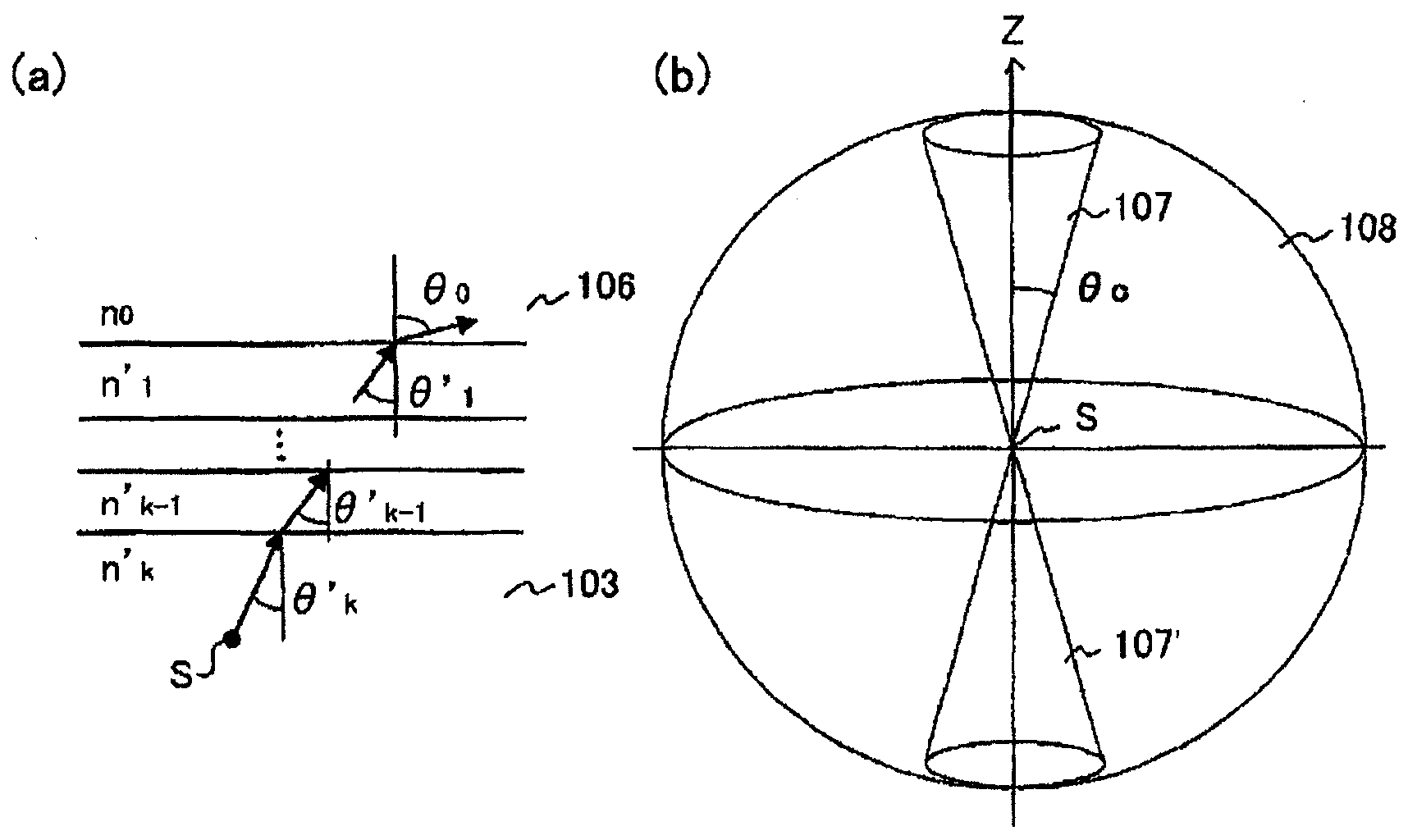

[0103] Figure 12 The cross-sectional structure and light propagation of the light emitting device using the organic EL element in the first embodiment are shown. An electrode 2 , a light emitting layer 3 , and a transparent electrode 4 are stacked in this order on a substrate 1 , and a transparent substrate (transparent protective layer) 5 is formed on the transparent electrode 4 . The substrate 1, the electrode 2, the light-emitting layer 3, and the transparent electrode 4 constitute a luminous body. On the surface of the transparent substrate 5 is formed a surface structure 13 divided into minute domains and having fine unevenness.

[0104] A voltage is applied between the electrode 2 and the transparent electrode 4, and the point S inside the light-emitting layer 3 emits light. The light passes through the transparent electrode 4 directly or after being reflected by the electrode 2, and i...

no. 2 approach

[0135] based on Figure 22 , Figure 23 A second embodiment will be described. In the second embodiment, only the pattern of the surface structure 13 is different from the first embodiment, and the other structures are completely the same as those of the first embodiment, and descriptions of the common structures are omitted.

[0136] In the second embodiment, the convex ratio P and the concave ratio 1-P of the surface structure are not fixed at 0.5, but are set at P=0.4 to 0.98. That is, the micro-region δ 1 (Area protruding upward) exists 40-98%, micro-region δ 2 (Concavity) exists in 60-2%.

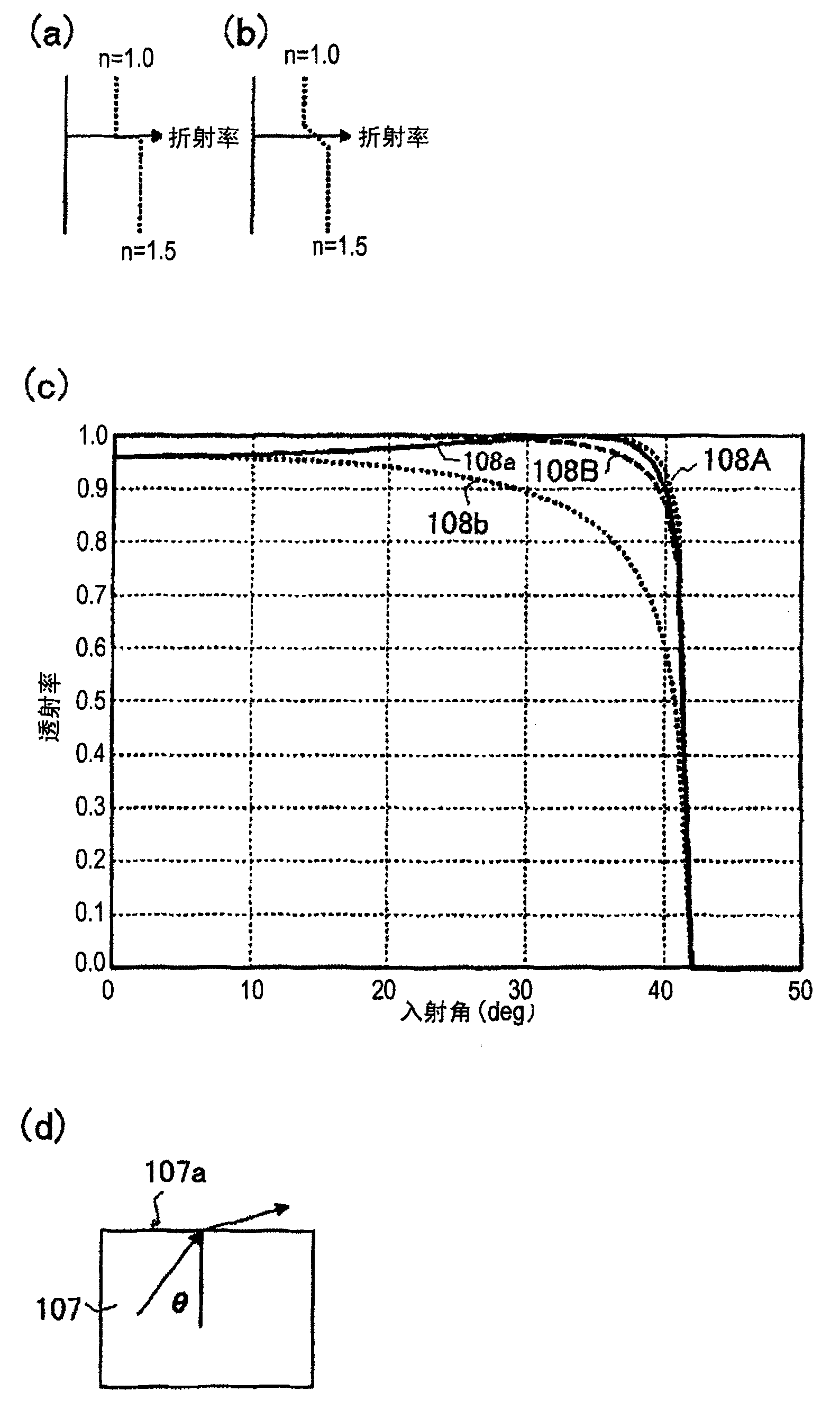

[0137] Figure 22 (a) is a graph explaining the light extraction efficiency of the surface structure of this embodiment, showing the refractive index n of the transparent substrate 5 1 =1.457, the refractive index n of air 6 0 = 1.0, the wavelength λ of light = 0.635 μm, the protrusion height of the surface structure d = 0.70 μm, the horizontal axis is the boundary width w of th...

no. 3 approach

[0142] based on Figure 22 (b) The third embodiment will be described. In the third embodiment, only the height difference condition of the surface structure 13 is different, and other structures are completely the same as those of the first and second embodiments, and descriptions of common structures are omitted.

[0143] In the third embodiment, two adjacent minute regions δ of the surface structure in the first and second embodiments are 1 ,δ 2 The amount of height difference between randomizes the case. As a way to achieve randomness, in Figure 13 In (a), the surface of the transparent substrate 5 is divided into checkerboard grids (small square regions δ) of width w (referred to as the boundary width) without gaps, and random function is used in each grid with respect to a single reference plane. set-d m / 2~d m / 2 between any height (or depth). As a single reference plane, in the direction parallel to the surface normal of the surface of the transparent substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com