Animal bone meal preparation process

A preparation process, a technology of animal bone meal, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve problems such as inability to solve defects, inability to completely remove organic matter, etc., to achieve easy operation and implementation, easy to be absorbed, process Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

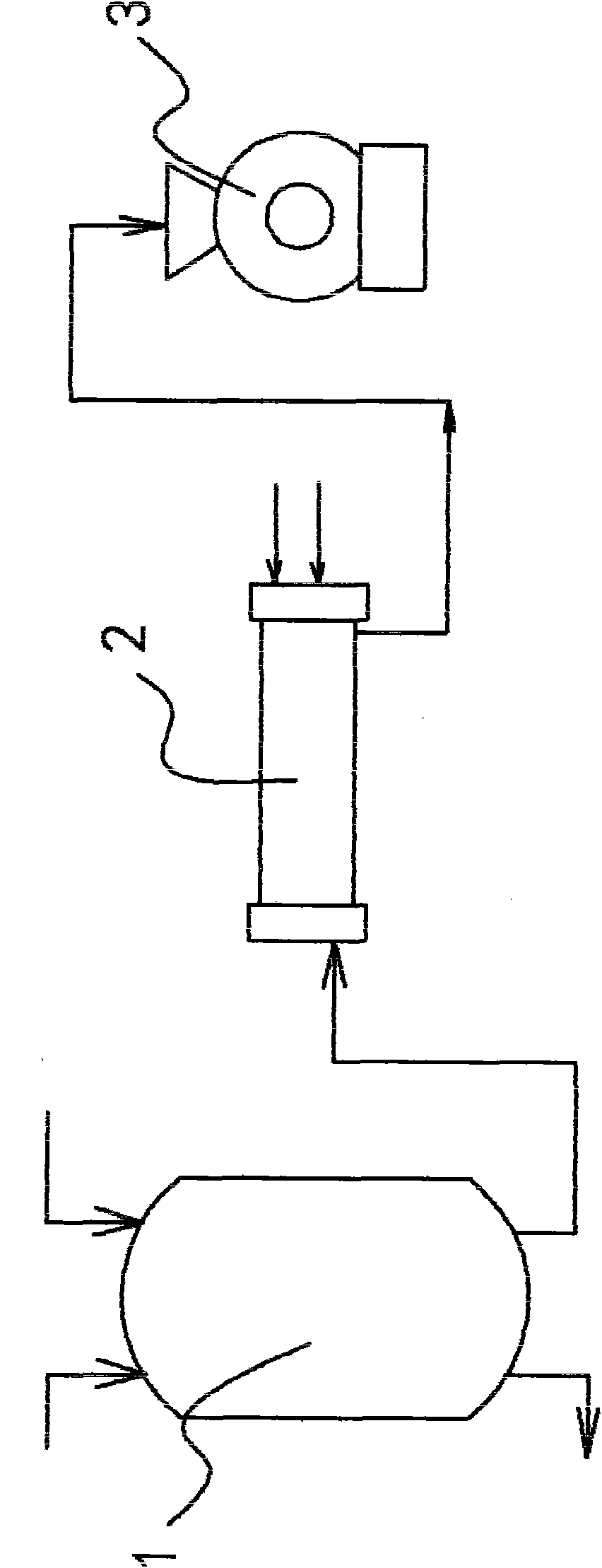

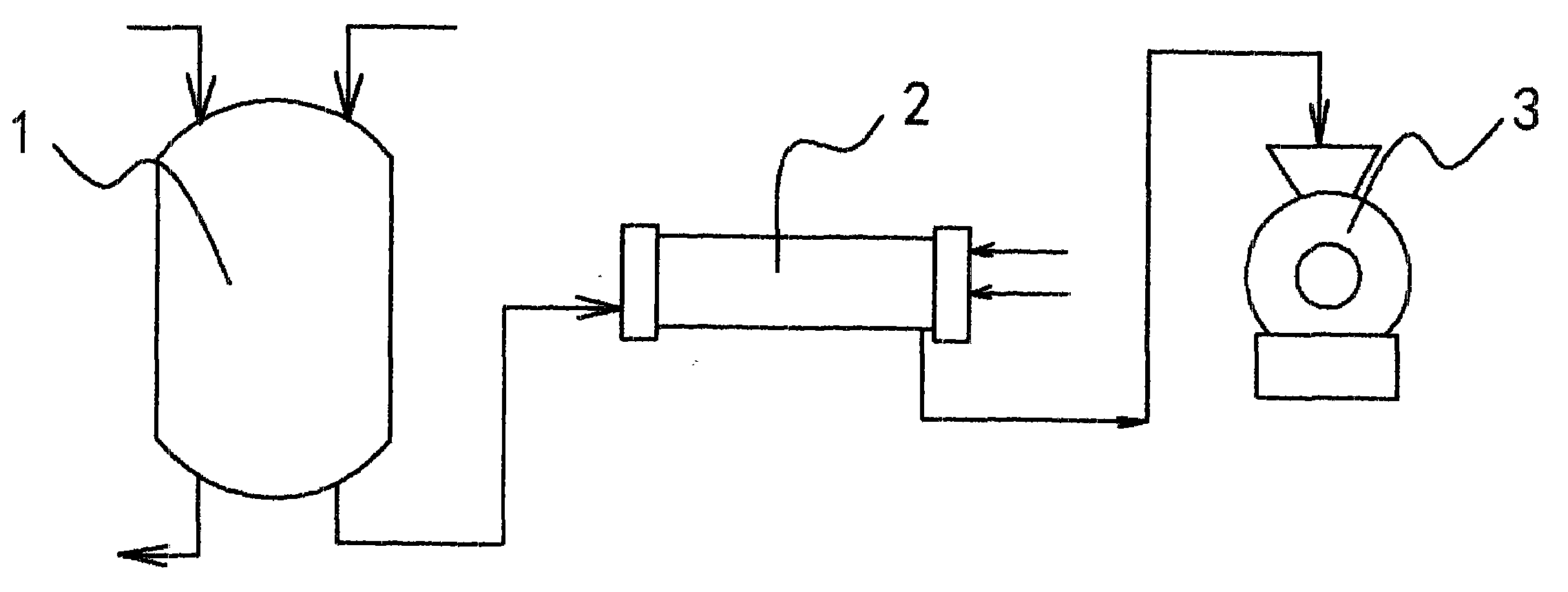

[0019] This animal bone powder preparation technology comprises the following steps (combining figure 1 shown):

[0020] A. Cooking: Wash the animal bones with water and smash them into bone pieces, place the animal bones and clear water in the cooking container 1, and the weight of the animal bones and the clear water in the cooking container 1 are equal. Then carry out steaming, steaming temperature is 120 ℃-140 ℃, preferably temperature is 130 ℃. During the heating process, steam with a pressure of 0.2-0.4 MPa is input into the cooking vessel 1, and the cooking time is 1.5-2.5 hours, and then the liquid product is separated. The preferred pressure value of the steam is 0.25MPa, and the cooking time is preferably 2 hours. In this embodiment, 10 tons of animal bones and clear water are weighed.

[0021] B. Calcination: place the cooked animal bones in the combustion furnace 2 for calcination at a temperature of 980°C-1020°C, and calcine until the weight is 28%-32% of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com