Radial flow adsorber

An adsorber and radial flow technology, applied in the field of new radial flow adsorbers, can solve the problem of uneven air distribution of radial flow adsorbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

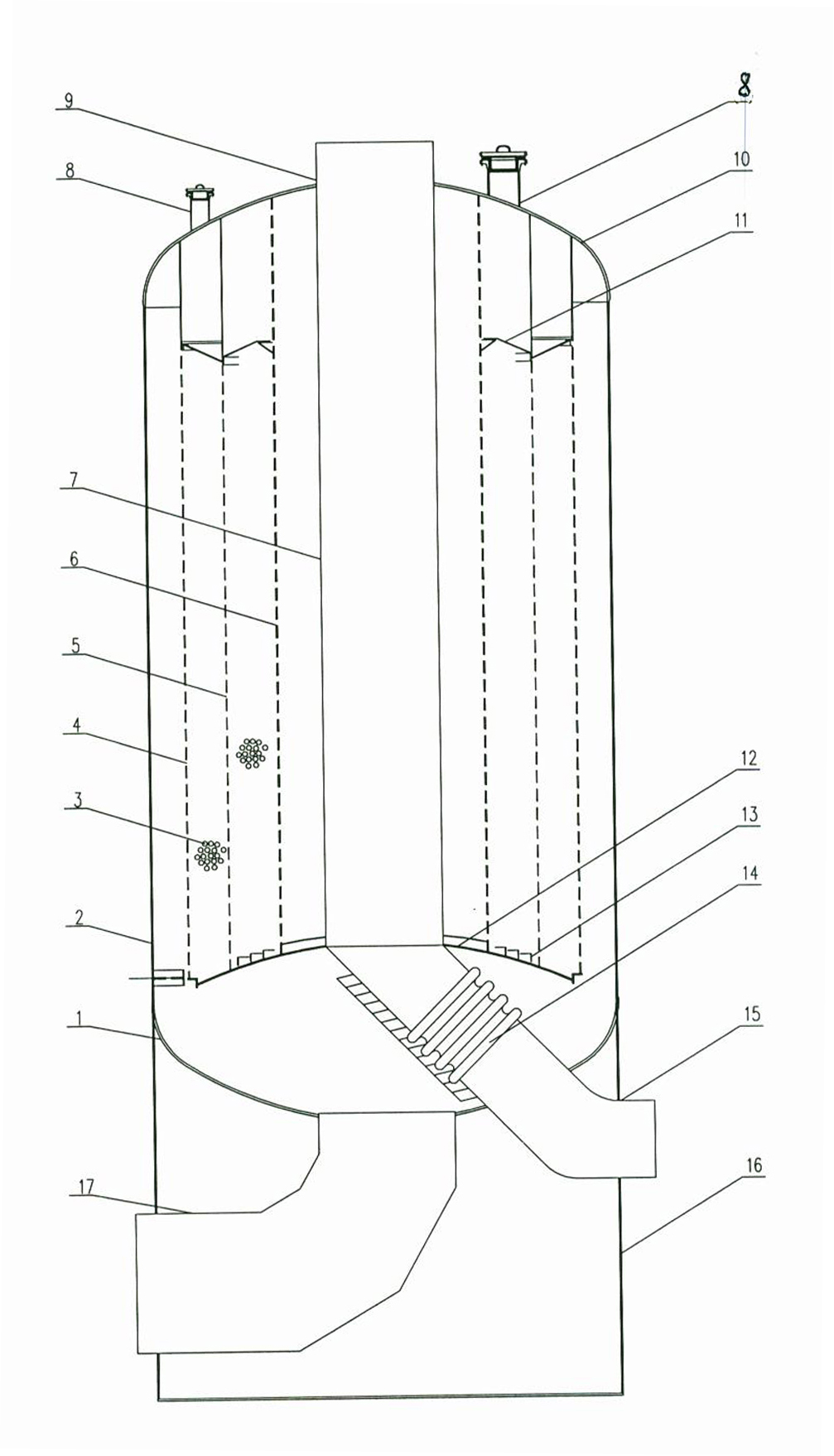

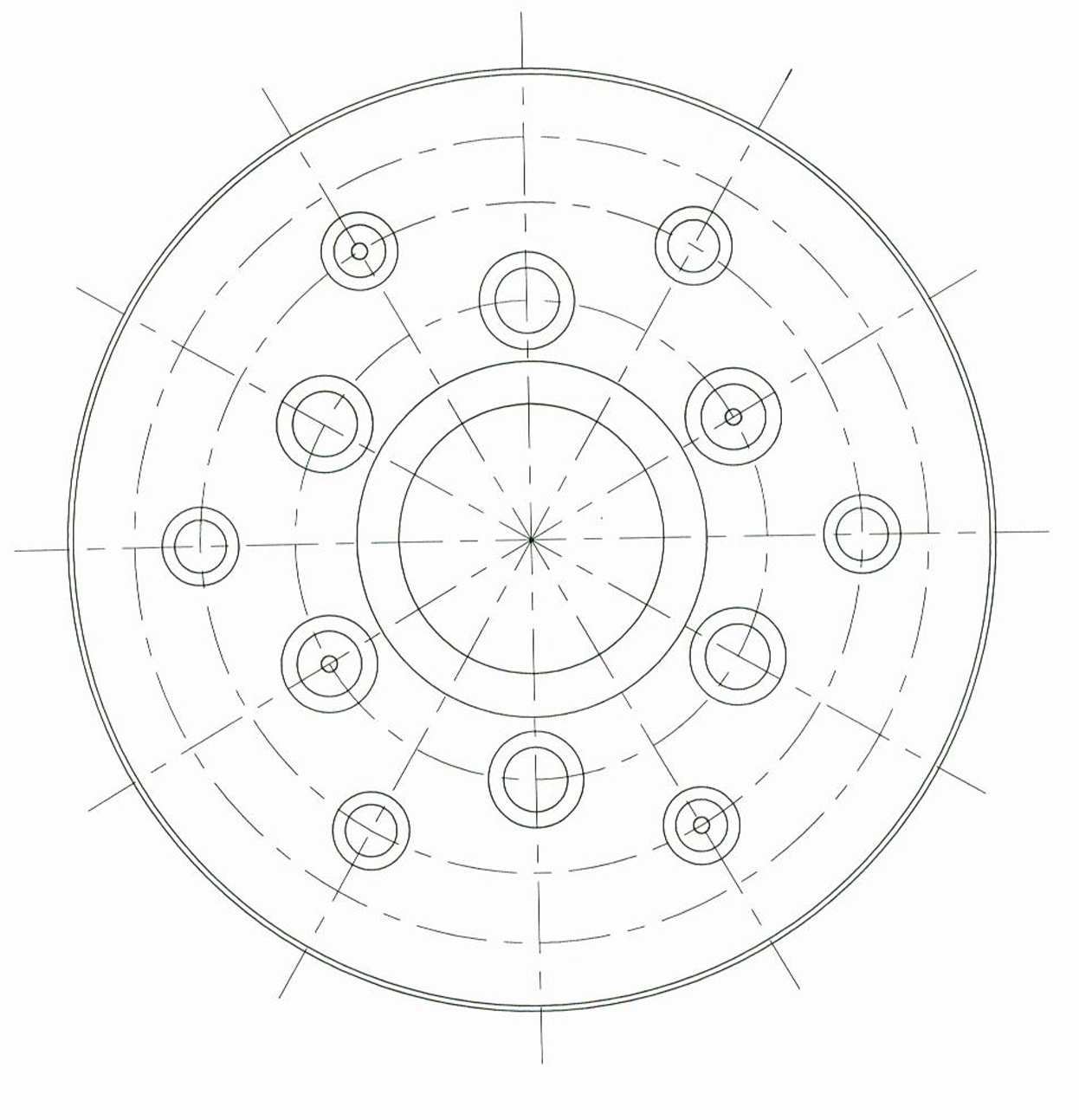

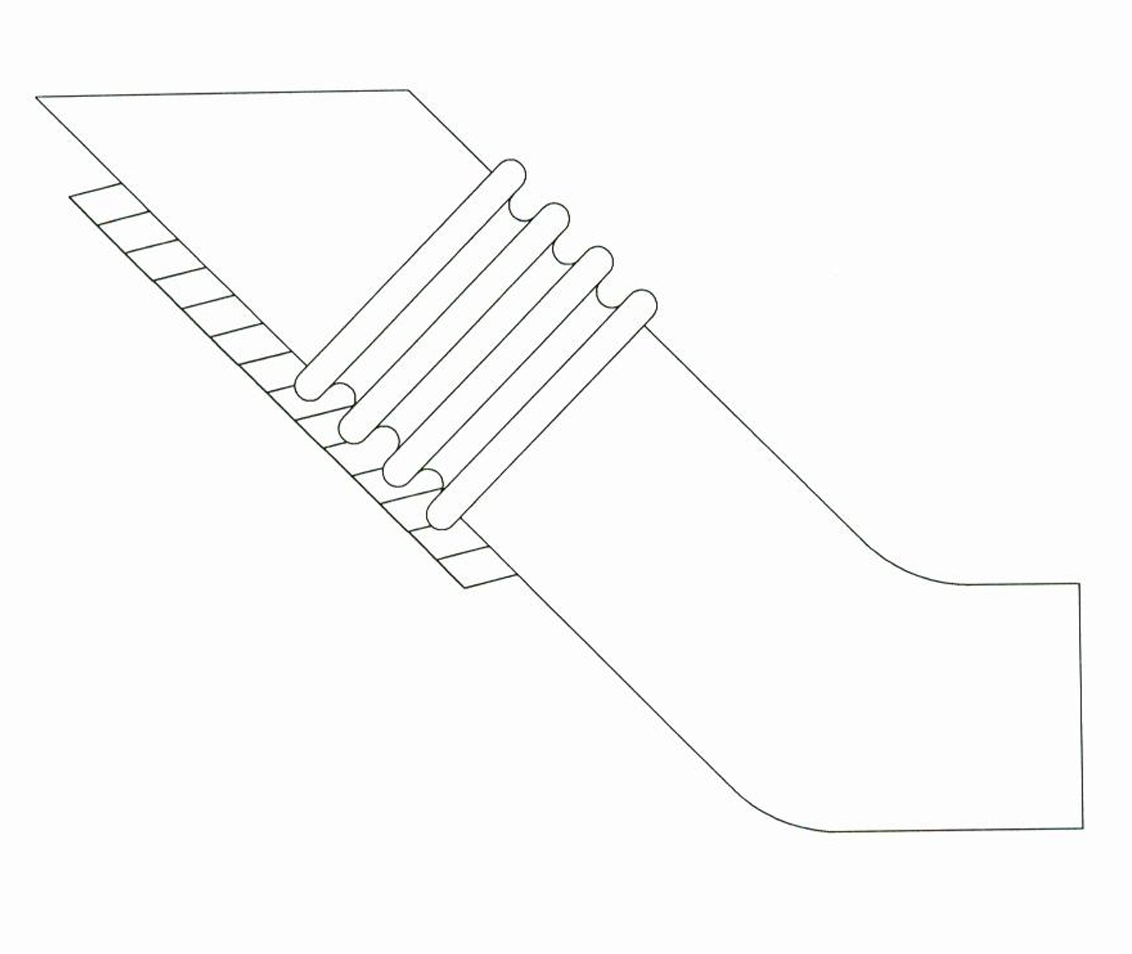

[0013] The invention will be described in detail below in conjunction with the accompanying drawings: figure 1 As shown, the present invention mainly includes: a lower head 1, an upper head 10, a cylinder 2 and a skirt 16, and the upper head 10 is provided with an upper inlet pipe 9 for regeneration gas and a loading port 8 for the adsorbent, See figure 2 As shown; the lower head 1 is provided with a gas inlet pipe 17 for gas inflow, and the cylinder 2 is provided with an adsorbent 3, a wire mesh and a filter element 7, and the wire mesh includes an outer mesh 4, a middle mesh Net 5, inner net 6; the lower sealing head 1 is also provided with a regeneration gas lower inlet pipe 15 communicated with the regeneration gas upper inlet pipe 9; with a regeneration gas upper inlet pipe 9 and a regeneration gas lower inlet pipe 15, During normal operation, the air flows into the adsorber from the gas inlet pipe 17, and flows out from the upper inlet pipe 9 of the regeneration gas an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com