Method and device for measuring external diameter of heavy-calibre seamless steel pipe on line by using CCD (Charge Coupled Device) cameras

A technology of seamless steel pipe and camera, applied in the field of automation instrumentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

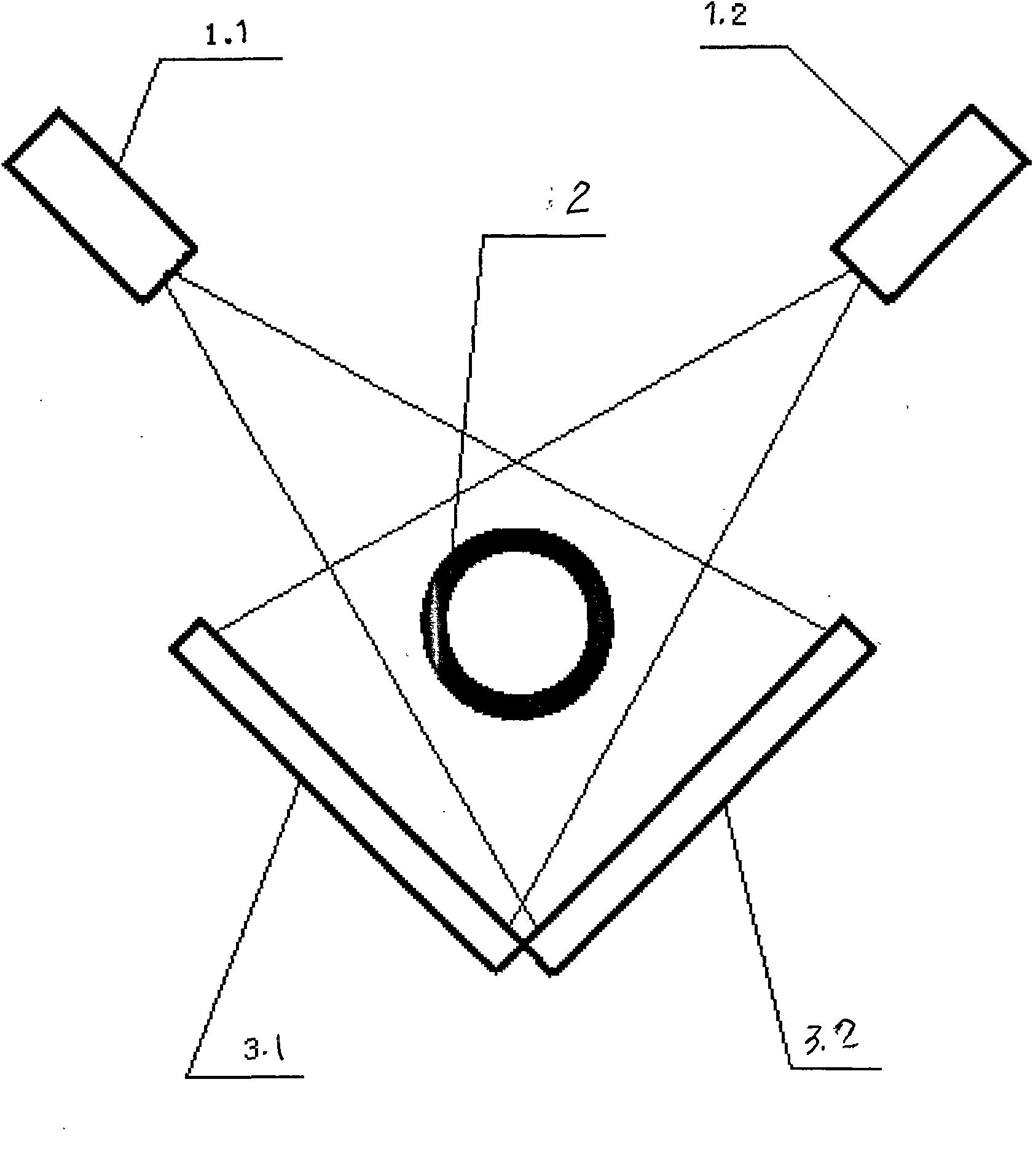

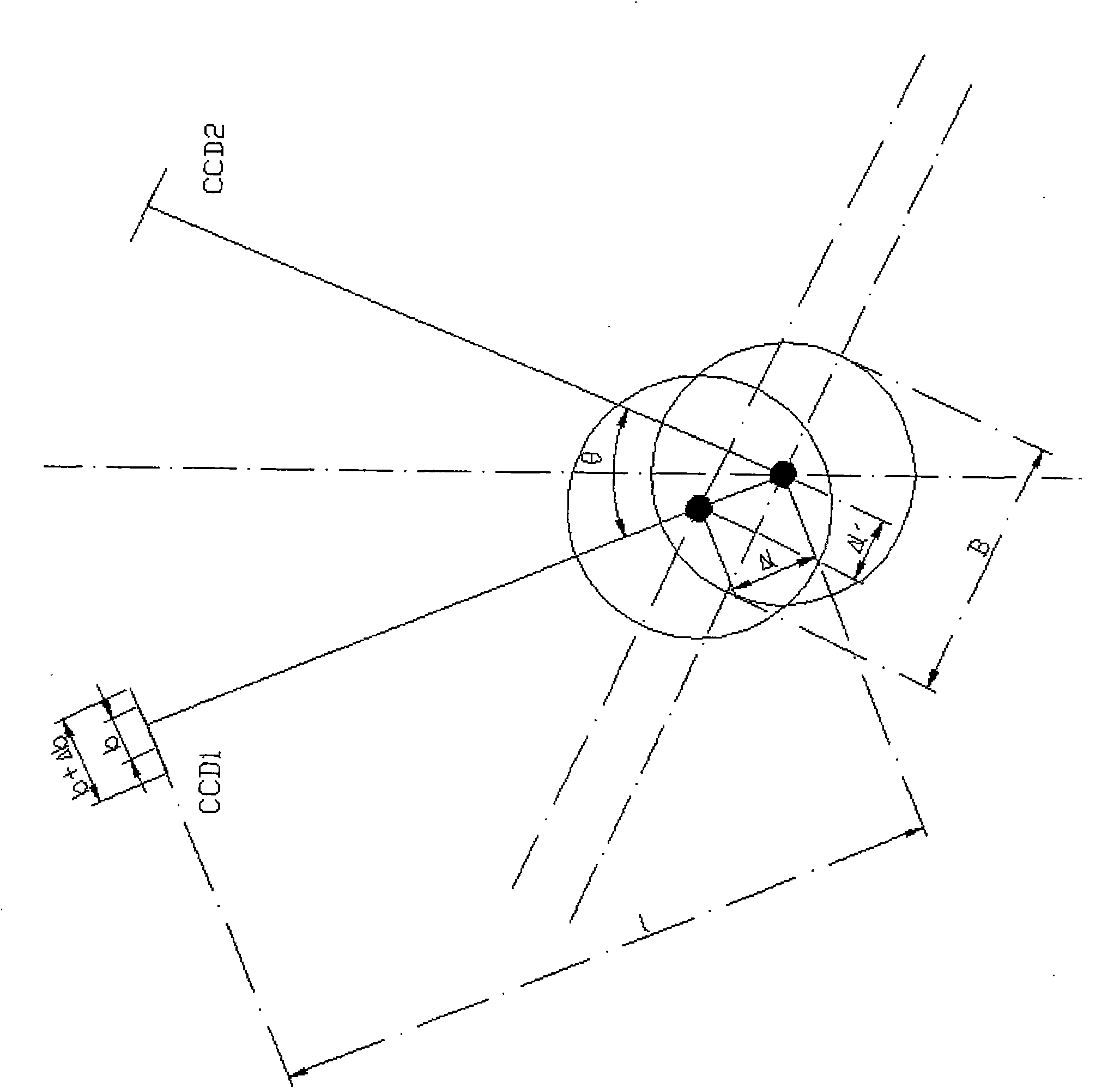

[0039] The intelligent camera for measuring the outer diameter of large-diameter seamless steel pipe applies the principle of binocular vision to the online measurement of the outer diameter of large-diameter seamless steel pipe

[0040] Technical scheme of on-site calibration method calling Matlab interpolation function

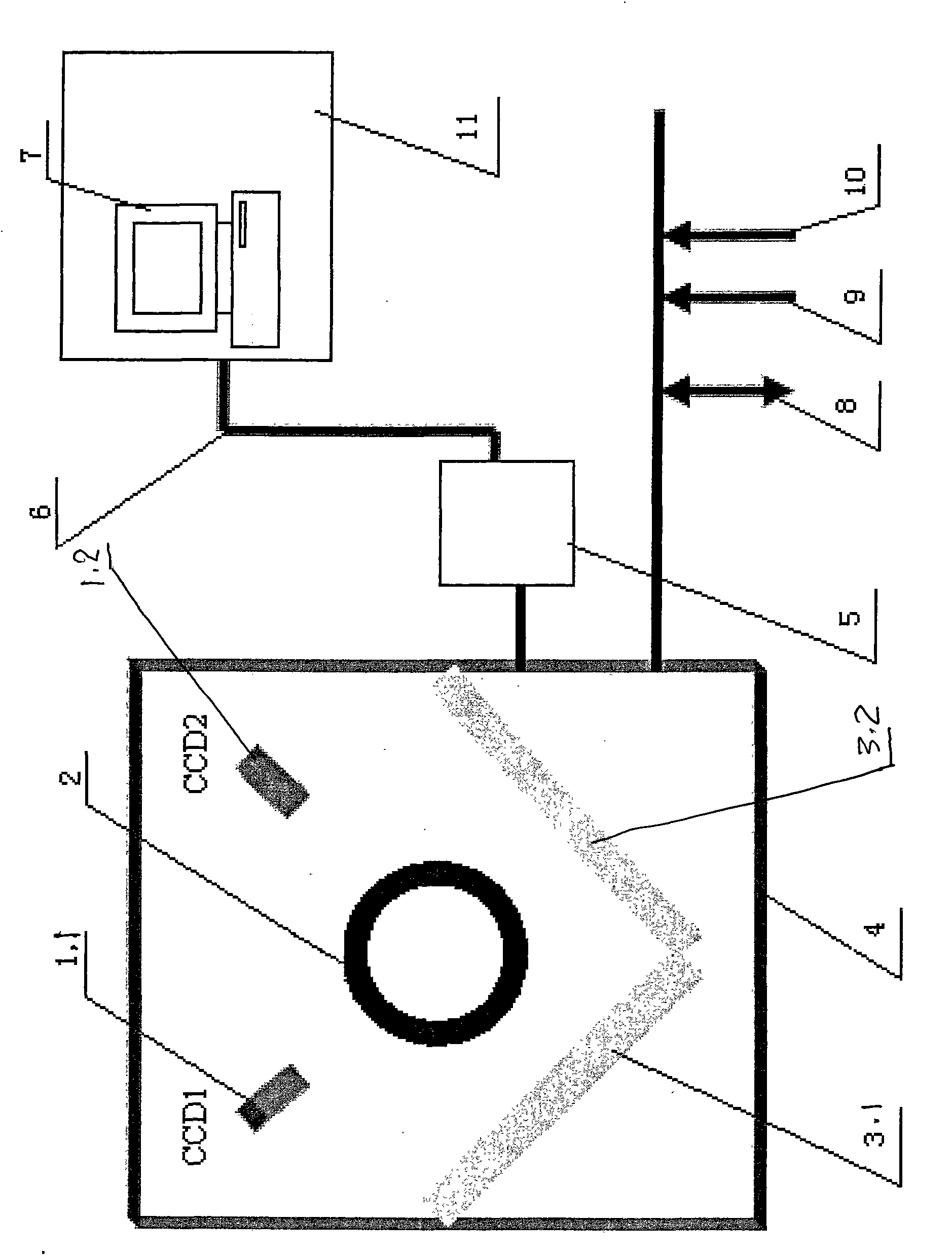

[0041] Large-diameter seamless steel pipe outer diameter online measurement system such as figure 1 shown.

[0042] A device for online measurement of the outer diameter of large-diameter seamless steel pipes using a CCD camera, which is characterized in that: two CCD cameras are respectively arranged above the rolling line of the large-diameter seamless steel pipe, and respectively above the rolling line of the large-diameter seamless steel pipe. Set up two background light boxes, two CCD cameras are respectively matched with the two background light boxes, the two CCD cameras and the two background light boxes are installed on the measurement frame, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com