Efficient cooling aluminum profile hot extrusion die structure

A technology of hot extrusion dies and aluminum profiles, applied in the direction of metal extrusion dies, etc., can solve problems such as poor cooling effect of liquid nitrogen, and achieve the effects of improving life, increasing strength, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

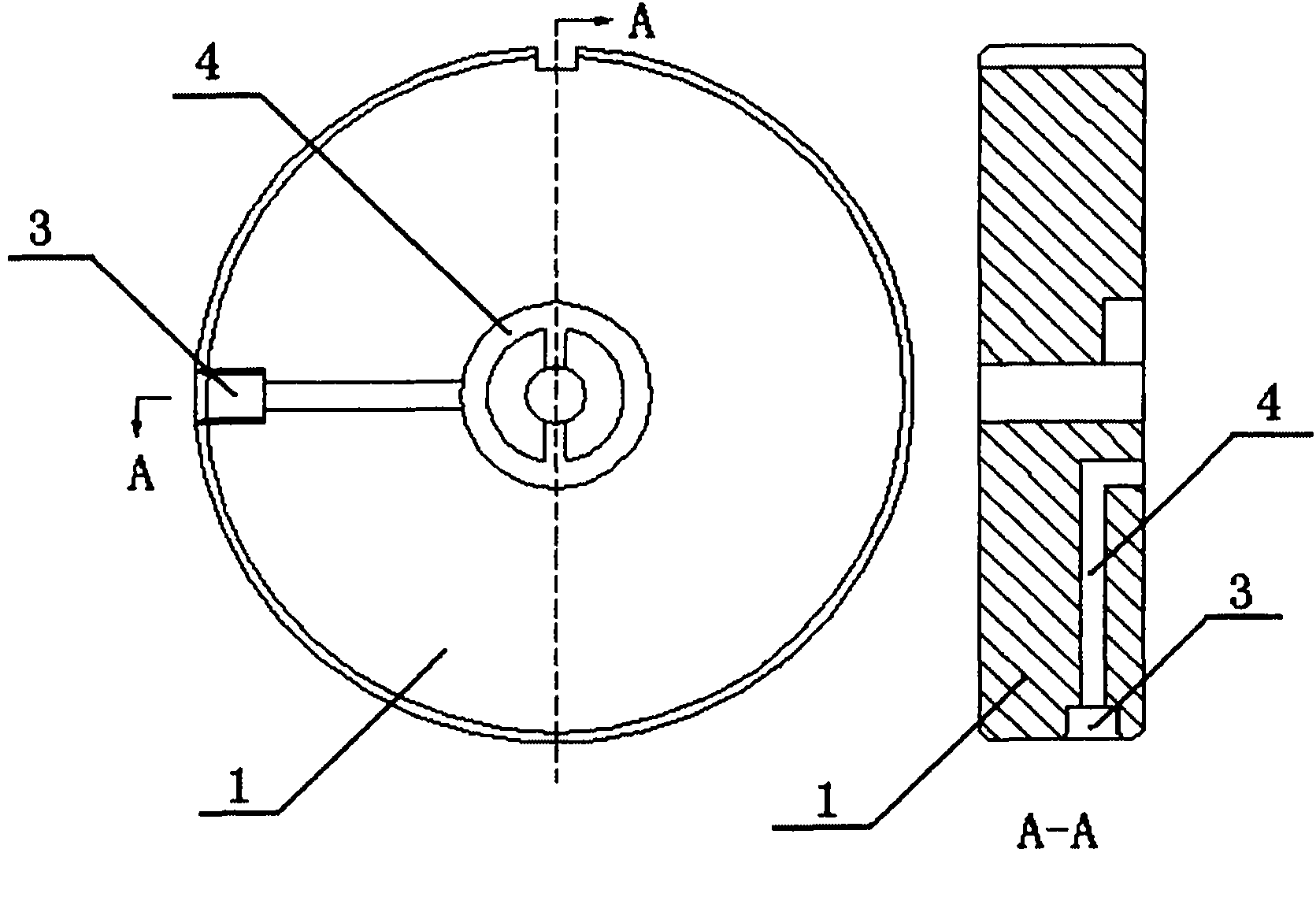

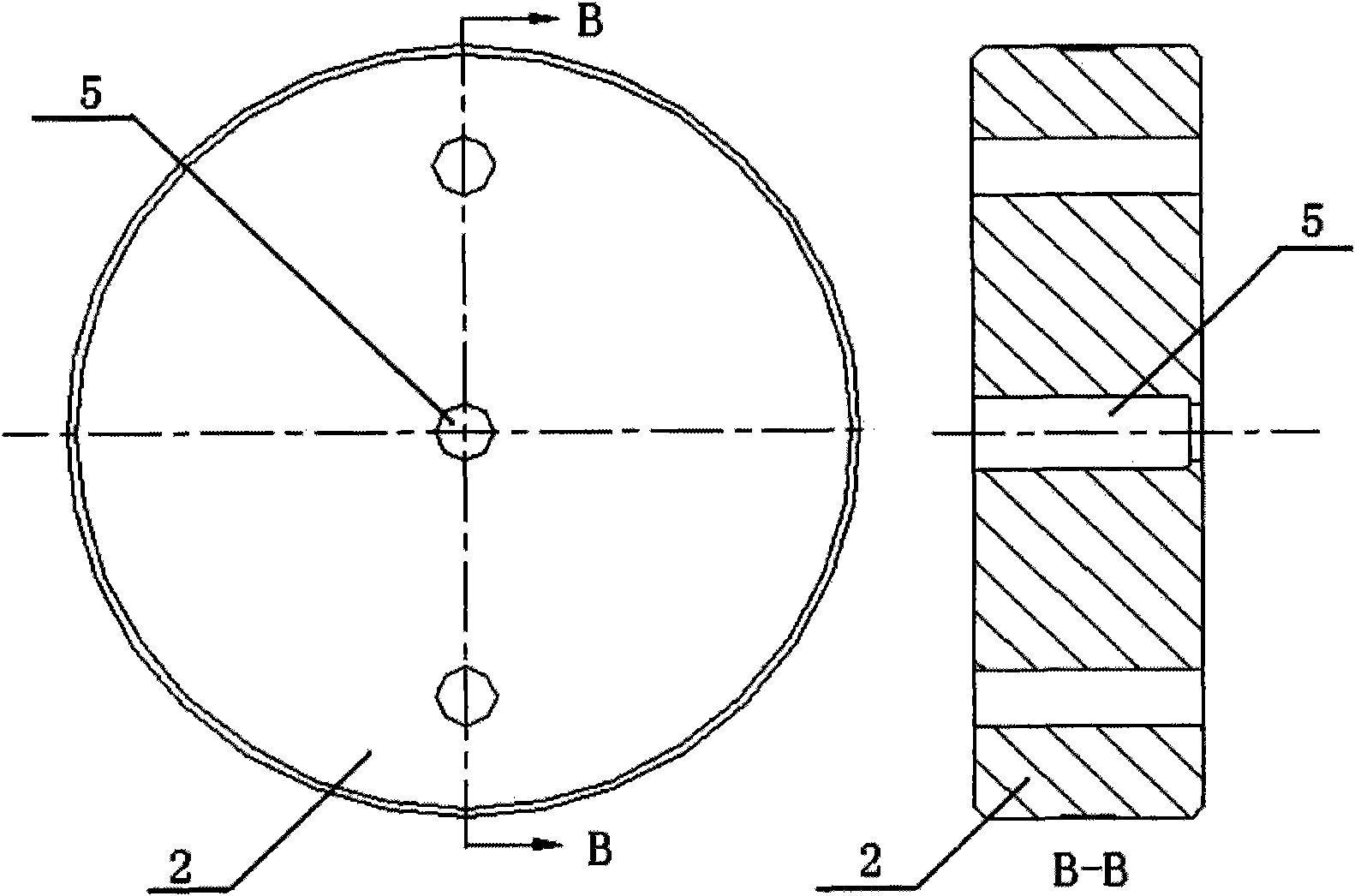

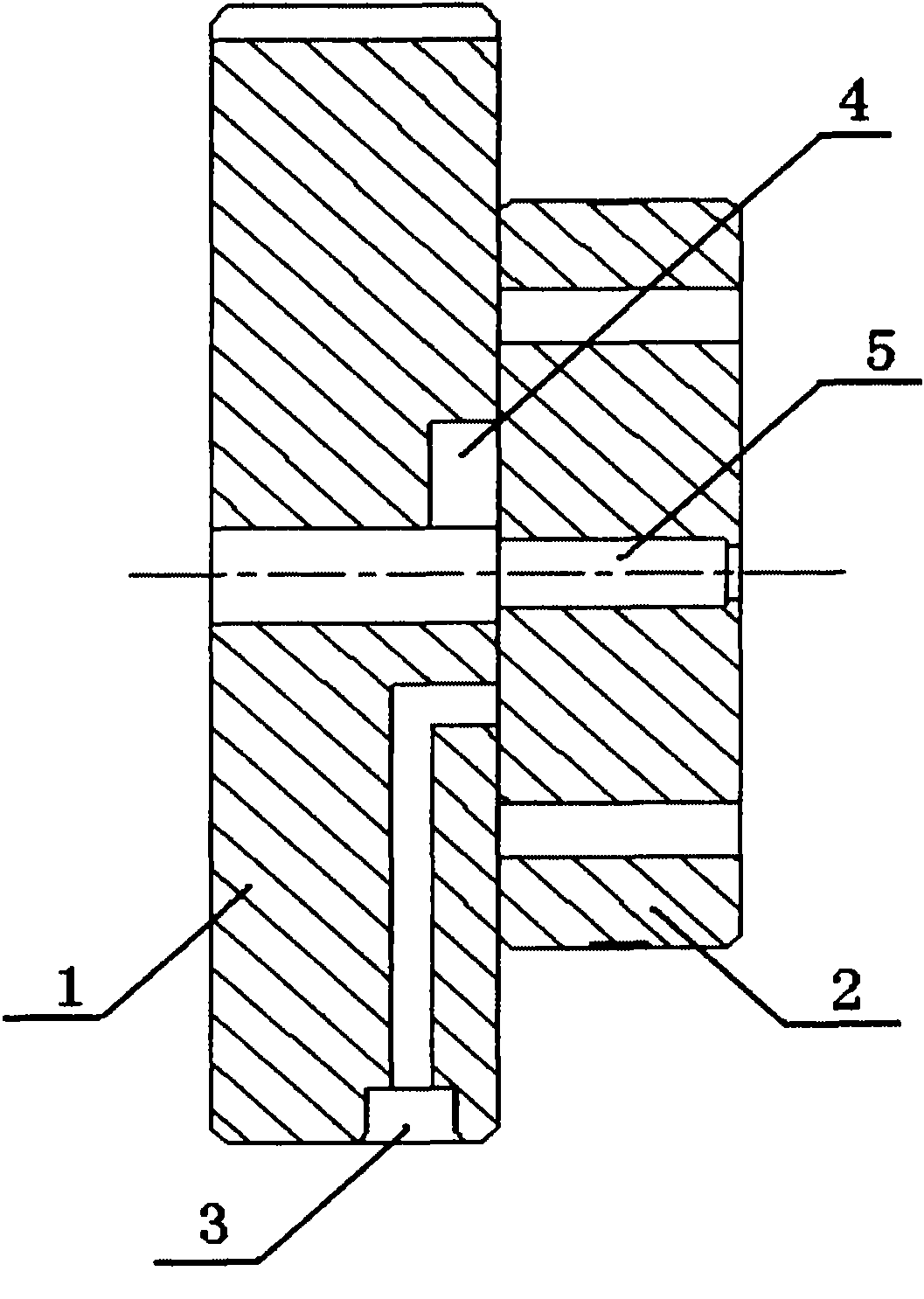

[0016] Such as figure 1 , figure 2 As shown, the prior art aluminum profile hot extrusion die is provided with a liquid nitrogen inlet 3 on the die pad 1 , and a liquid nitrogen channel 4 is provided on the die pad 1 and leads to the contact surface between the die pad 1 and the mold 2 . Such as image 3 As shown, there is a certain distance between the outlet of the liquid nitrogen channel 4 and the working belt 5 of the mold, which is not conducive to cooling.

[0017] Such as Figure 4 , Figure 5 As shown, the present invention is provided with a liquid nitrogen inlet 13 on the outer edge of the mold pad 11, and the liquid nitrogen channel 14 communicates with the liquid nitrogen inlet 13; the liquid nitrogen channel 14 is designed as a spiral at the contact surface part of the mold pad 11 and the mold 12 The outlet 17 of the liquid nitrogen passage 14 is int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com