Vibrational casting experimental device

A technology of vibration device and experimental device, which is applied in the field of vibration casting, can solve problems such as poor adaptability, and achieve the effects of convenient operation, low energy consumption and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

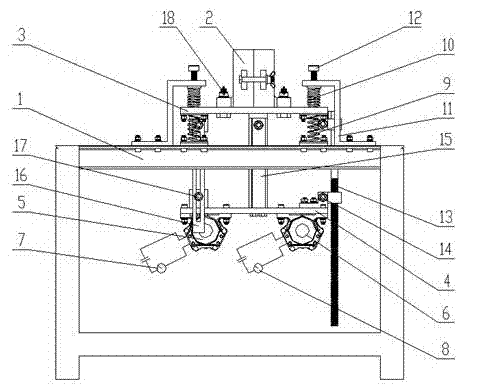

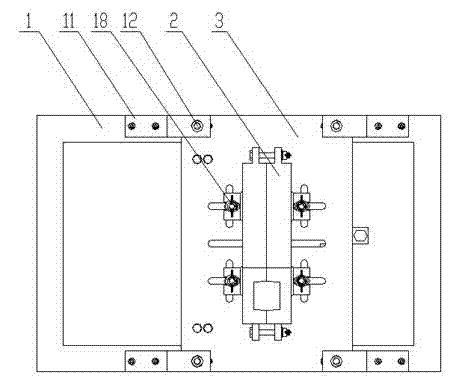

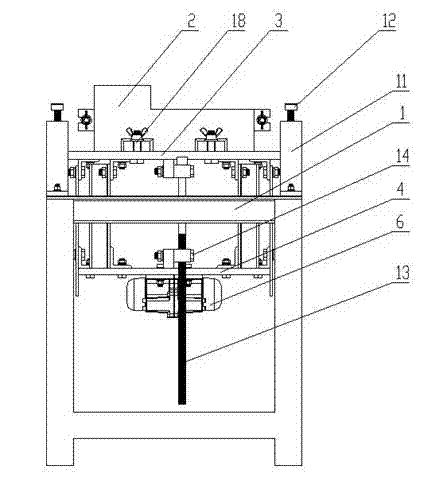

[0024] Such as Figure 1~3 As shown, the vibration casting device includes a frame 1, a sample mold 2, a mold installation device, a vibration device, a shock absorber and a vibration direction adjustment device.

[0025] The mold mounting device comprises a mold mounting plate 3 and a mold fastening bolt 18 for installing the sample mold 2, the mold mounting plate 3 is installed above the top of the frame 1 by a vibrating device, and the sample mold 2 is installed on the top of the frame 1 by the fastening bolt 18. Die mounting plate 3. The sample mold 2 can be installed by rotating 90°, and linear vibrations at different angles in the XOZ plane and YOZ plane can be obtained by changing the installation direction of the sample mold 2.

[0026] The damping device comprises a damping spring 9 , a compression spring 10 , a compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com