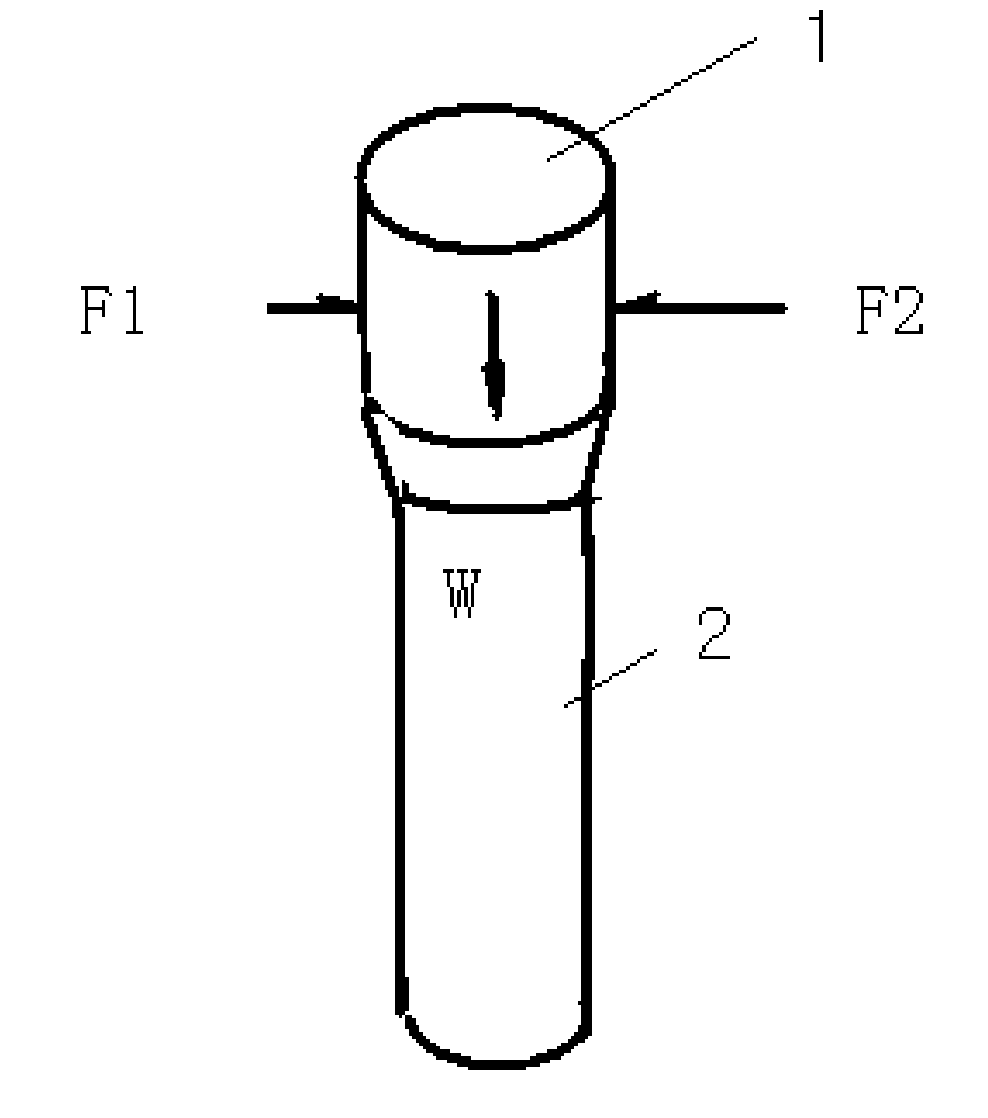

Vertical transfer passage and application thereof

一种输送通道、竖向的技术,应用在高空救生,军事,工程领域,能够解决外撑力大、胶管小弹性空间、适用范围小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

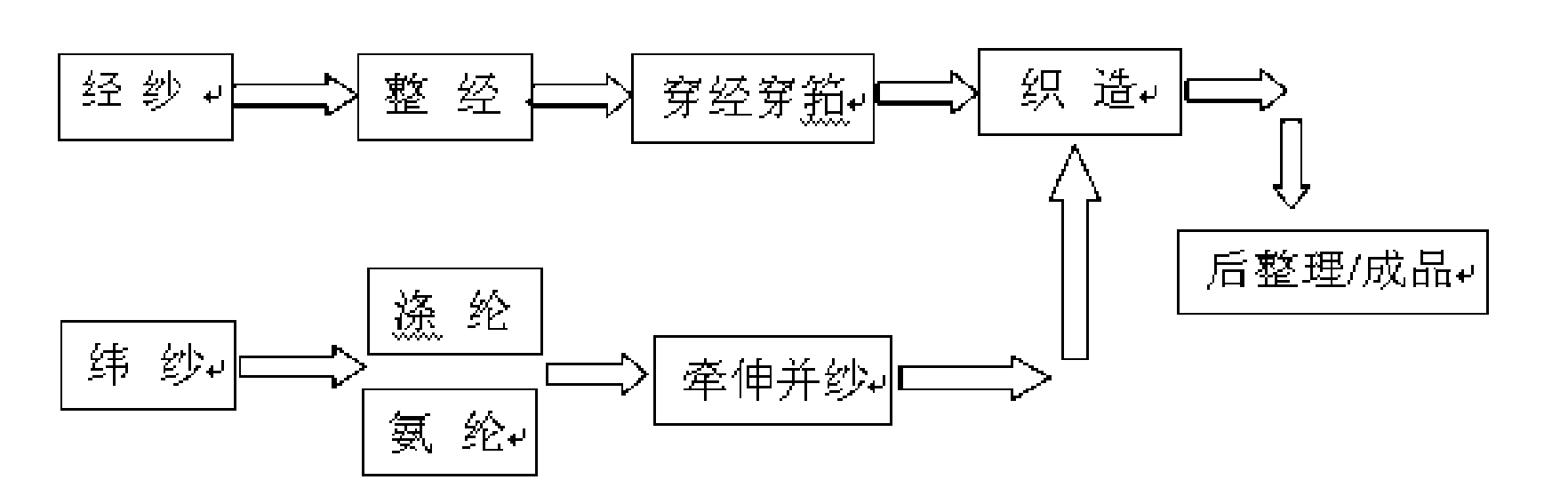

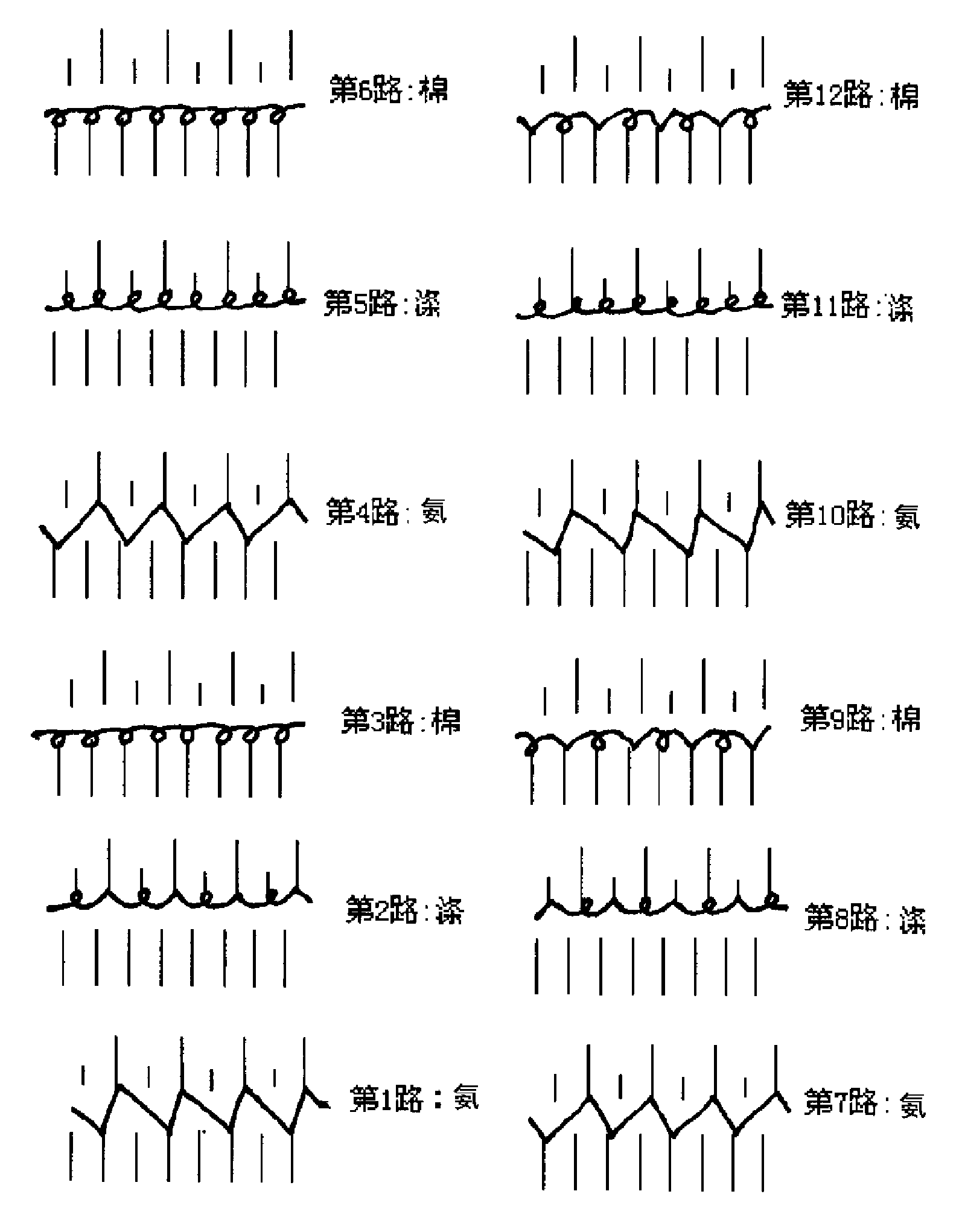

[0094] The experimental table is 22 meters high, and the fiber-based vertical vertical conveying channel adopts elastic fabric: polyester: 85%, spandex 15%, of which warp polyester is 100%, weft yarn is 200D / 48f polyester DTY filament and 140D / 2f (70D / 1f×2) Spandex network covering.

[0095] The elastic deformation rate in the weft direction of the fabric is 170%, the recovery force in the weft direction is 750N, the elastic recovery rate in the weft direction is 85%, the elongation at break in the warp direction is 20%, the breaking strength in the warp direction is 3000N, and the breaking strength in the weft direction is 2000N. The plastic deformation rate is 10%.

[0096] Among them, the fabric structure is: polyester 200D / DTY filaments are used in the warp direction, and 200D / 48f polyester DTY filaments and 140D / 2f (70D / 1f×2) spandex filaments are used for network covering in the weft direction.

[0097] Warp and weft density: 43.2 threads / cm, 66 threads / cm

[0098] Wi...

Embodiment 2

[0106] The test bench is 32 meters high, and the elastic fabric is used: polyester: 84%, spandex 16%, of which the warp yarn is 100% polyester, and the weft yarn is 200D / 48f polyester DTY filament and 140D / 2f (70D / 1f×2) spandex yarn network coating.

[0107] The elastic deformation rate in the weft direction of the fabric is 300%, the recovery force in the weft direction is 2000N, the elastic recovery rate in the weft direction is 94%, the elongation at break in the warp direction is 30%, the breaking strength in the warp direction is 4000N, and the breaking strength in the weft direction is 3500N. The plastic deformation rate is 8%.

[0108] Among them, the fabric structure is:

[0109] Warp 200D / 48f polyester DTY filament;

[0110] Weft 200D / 48f polyester DTY filament and 140D / 2f (70D / 1f×2) spandex yarn are networked and covered.

[0111] Warp and weft density: 54 threads / cm×65 threads / cm.

[0112] Width: 65cm.

[0113] Gram weight: 760g / m 2 .

[0114] The fiber-based...

Embodiment 3

[0120] The test bench is 22 meters high, and the vertical conveying channel is made of elastic fabric: 85% polyester and 15% spandex, of which the warp yarn is 100% polyester, and the weft yarn is 200D / 48f polyester DTY filament and 140D / 2f (70D / 1f×2) spandex Silk network coating.

[0121] The elastic deformation rate in the weft direction of the fabric is 140%, the recovery force in the weft direction is 550N, the elastic recovery rate in the weft direction is 80%, the elongation at break in the warp direction is 12%, the breaking strength in the warp direction is 1900N, and the breaking strength in the weft direction is 1000N. The plastic deformation rate is 13%.

[0122] The fabric structure is as follows: polyester 200D / DTY filaments are used in the warp direction, and 200D / 48f polyester DTY filaments and 140D / 2f (70D / 1f×2) spandex filaments are used for network covering in the weft direction.

[0123] Warp and weft density: 43.2 cm, 66 / cm

[0124] Width: 70cm

[0125] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com