Wastewater degradation device

The technology of a wastewater degradation device and a water outlet, which is applied in the field of water treatment, can solve the problems of low reaction efficiency and low decolorization rate of organic pollutants, and achieves the effects of high electrolysis efficiency and less side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

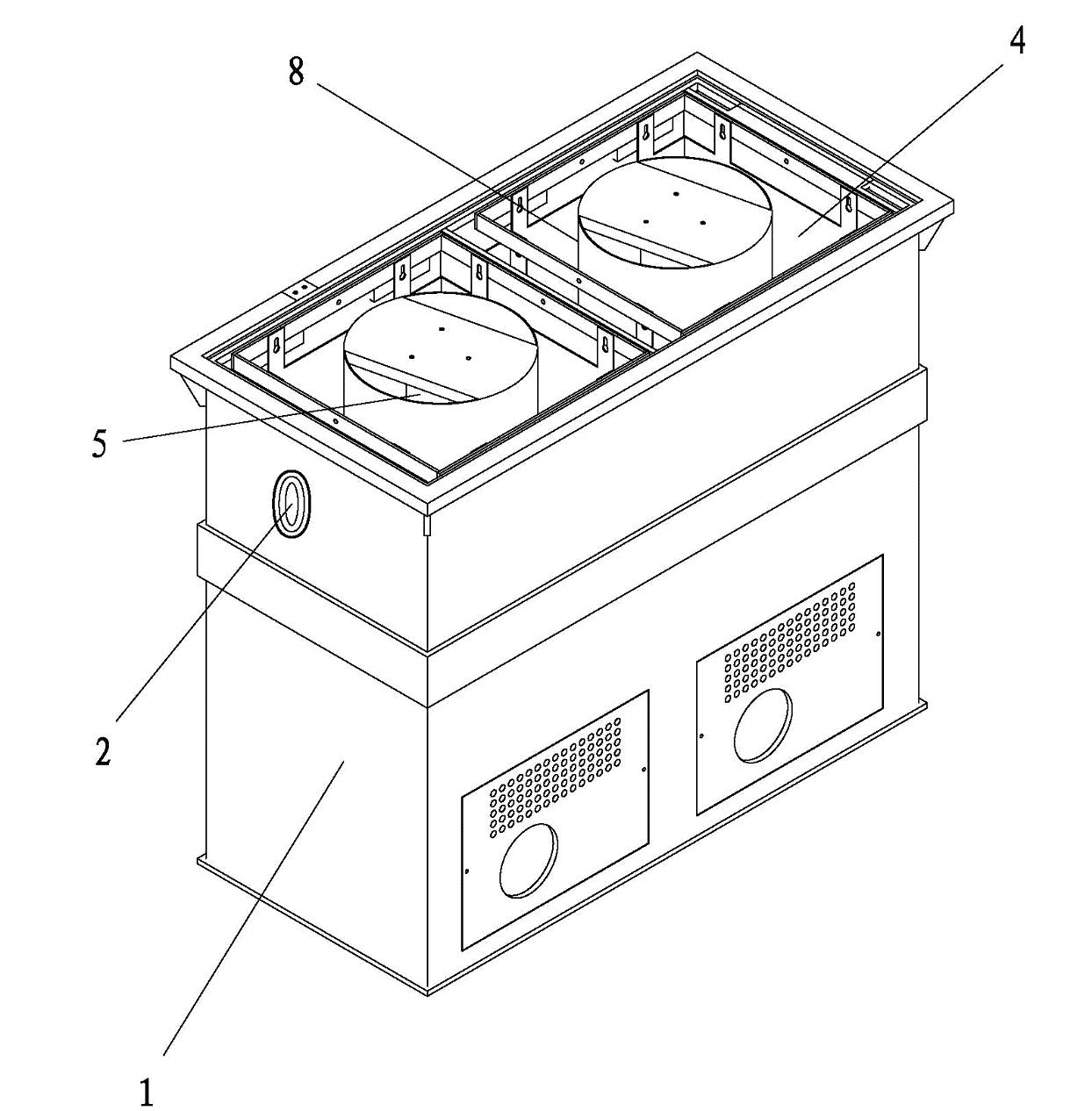

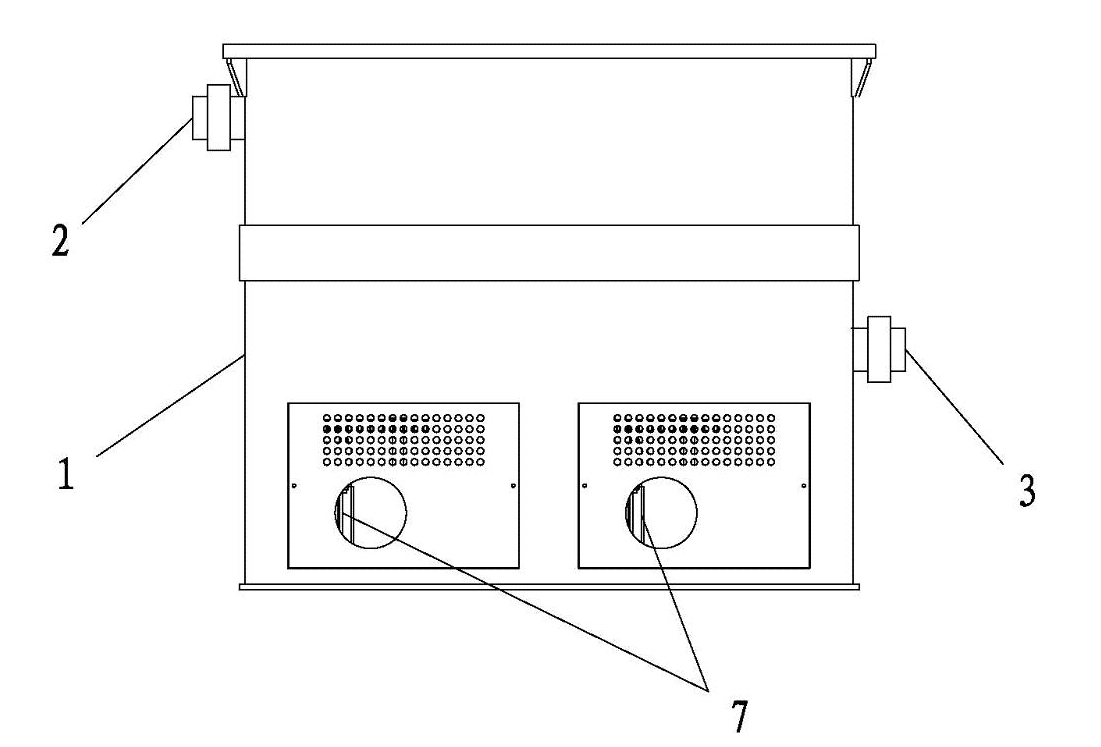

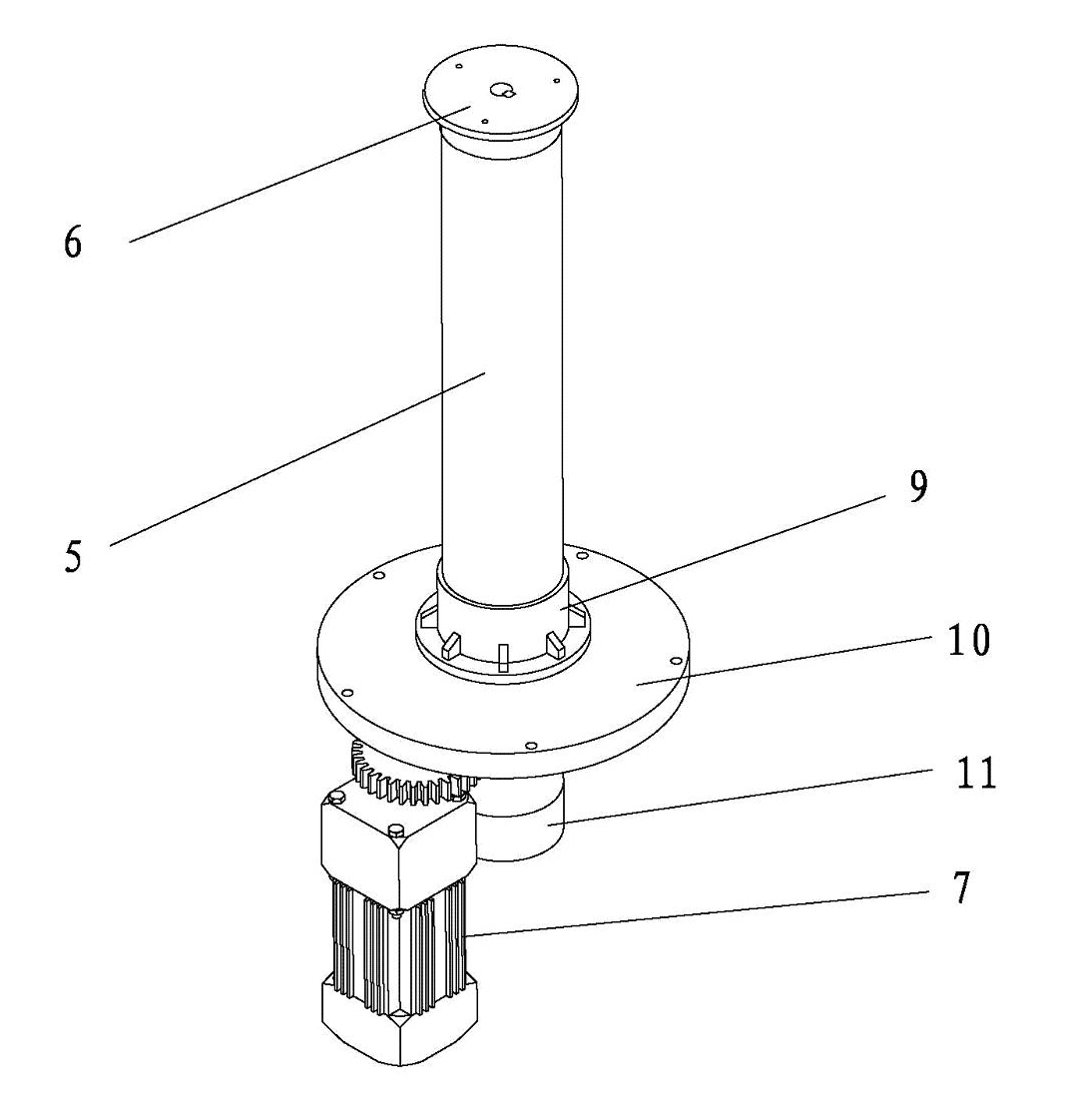

[0048] like Figures 1 to 4 As shown, the degradation device for treating organic wastewater containing heavy metal ions includes a housing 1, a water inlet 2 and a water outlet 3, a reaction chamber 4 is arranged in the housing 1, and the water inlet 2 and the water outlet 3 are arranged in the shell body 1 and communicate with reaction chamber 4. The size of the housing is 1130mm×580mm×995mm. There are two reaction chambers 4, and two electrodes are arranged in each reaction chamber 4. The dimensions of each reaction chamber are 460mm x 460mm x 430mm. The cathode in the first reaction chamber is composed of a rotatable electrode shaft 5 arranged in the middle of the reaction chamber and a deposition cylinder 8 sleeved on the electrode shaft 5, and the anode is inserted circumferentially around the deposition cylinder 8 on the inner wall of the reaction chamber , the anode is square, and the cathode is ring-shaped, so the pole spacing is not a fixed value, the maximum pole...

Embodiment 2

[0054] Such as Figures 1 to 4 As shown, the wastewater degradation device for treating industrial wastewater containing organic pollutants includes a housing 1, a water inlet 2 and a water outlet 3, and a reaction chamber 4 is arranged in the housing 1, and the water inlet 2 and the water outlet 3 It is arranged on the casing 1 and communicates with the reaction chamber 4 . The size of the housing is 1130mm×580mm×995mm. There are two reaction chambers 4, and two electrodes are arranged in each reaction chamber 4. The dimensions of each reaction chamber are 460mm x 460mm x 430mm. The anode in each reaction chamber is composed of a rotatable electrode shaft 5 located in the middle of the reaction chamber and a deposition cylinder 8 sleeved on the electrode shaft 5, and the cathode is inserted in the reaction chamber circumferentially around the deposition cylinder 8. 4 inner walls. Because the cathode is square, the pole spacing is not a fixed value, the maximum pole spacin...

Embodiment 3

[0056] as Figures 1 to 4 As shown, the wastewater degradation device for treating industrial wastewater containing organic pollutants includes a housing 1, a water inlet 2 and a water outlet 3, and a reaction chamber 4 is arranged in the housing 1, and the water inlet 2 and the water outlet 3 It is arranged on the casing 1 and communicates with the reaction chamber 4 . The size of the housing is 1130mm×580mm×995mm. There are two reaction chambers 4, and two electrodes are arranged in each reaction chamber 4. The dimensions of each reaction chamber are 460mm x 460mm x 430mm. The anode in each reaction chamber is composed of a rotatable electrode shaft 5 located in the middle of the reaction chamber and a deposition cylinder 8 sleeved on the electrode shaft 5, and the cathode is inserted in the reaction chamber circumferentially around the deposition cylinder 8. 4 inner walls. Because the cathode is square, the pole spacing is not a fixed value, the maximum pole spacing is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com