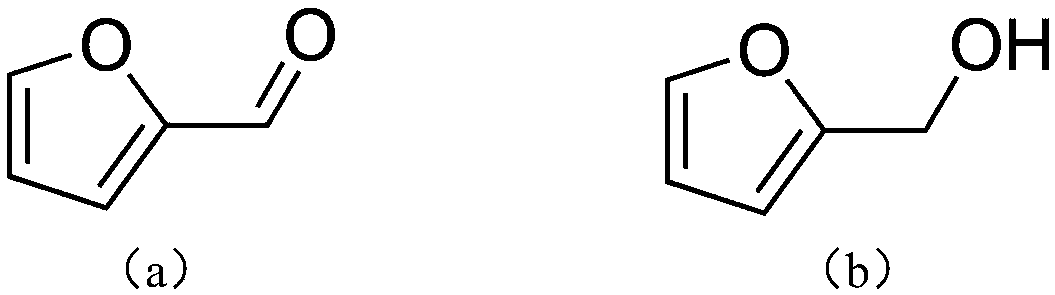

Preparation method of furfuryl alcohol

A technology of furfuryl alcohol and furfural, applied in the fields of biocatalysis and biomanufacturing, can solve the problems of restricting economy and practicability, increasing the difficulty of separation and purification of products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Acclimatization and activation of Pichia pastoris SC1103: Pichia mongolia SC1103 strains were inserted into yeast extract powder peptone glucose (YPD) liquid medium containing 5mM HMF (1% yeast extract, 2% peptone and 2% glucose ), after culturing at 30°C and 200r / min for 12h, the above-mentioned bacterial suspension was introduced into fresh YPD liquid medium containing 5mM HMF with an inoculum size of 2%, and cultivated at 30°C and 200r / min for 12h. Subsequently, the above-mentioned bacterial suspension was successively inserted into yeast extract powder peptone glucose liquid medium containing 10 and 15 mM 5-hydroxymethylfurfural with an inoculation amount of 2%, and similar steps were adopted for acclimation respectively. Put the above-mentioned acclimatized Pichia mongolica SC1103 strain into YPD liquid medium, and after culturing at 30°C and 200r / min for 12h, add the above-mentioned bacterial suspension into fresh YPD liquid with an inoculum amount of 2%. In the c...

Embodiment 2

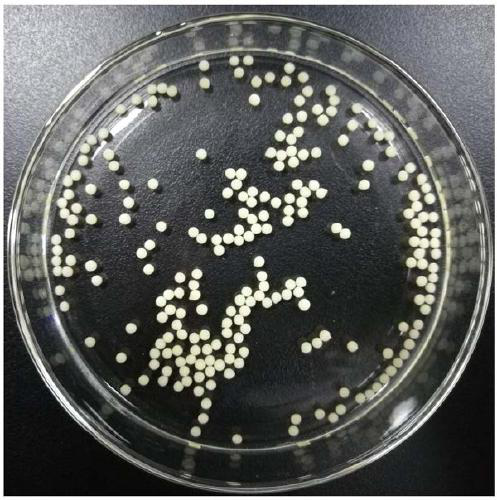

[0030] Immobilization of Pichia mongolica SC1103: Weigh 2.5g of sodium alginate into a Erlenmeyer flask, add 100mL of distilled water, and heat to dissolve. After the solution was cooled to room temperature, the cells acclimated and activated in Example 1 were added at a concentration of 200 mg / mL-600 mg / mL (based on the wet weight of the cells). Add 0.2M CaCl drop by drop with a sterile syringe 2 After standing in the solution for 4 hours to solidify, the solution was washed with Tris-HCl buffer (100 mM, pH 8) for 3 times, and stored in a refrigerator at 4°C for use.

Embodiment 3

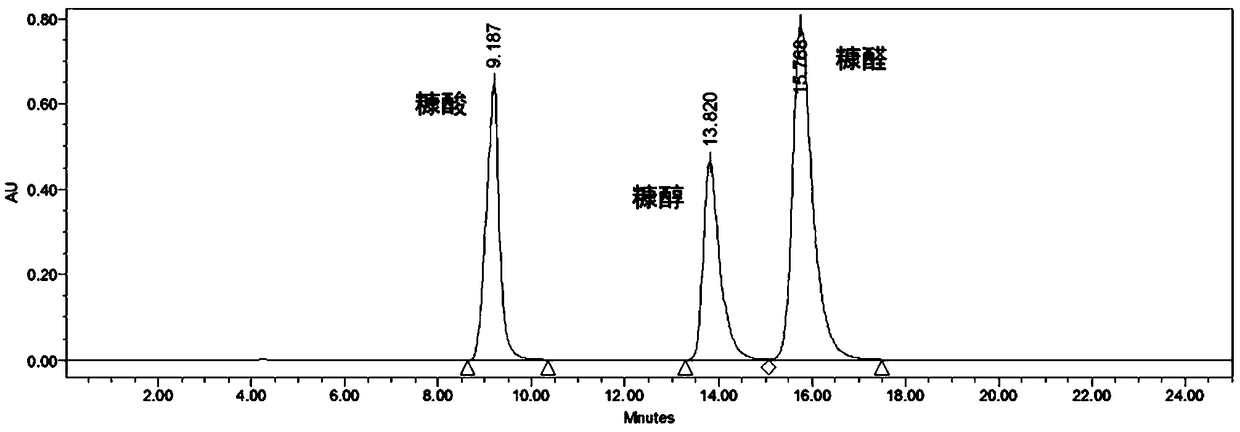

[0032] Add furfural and glucose to 4mL acetate buffer (50mM, pH 5) and mix evenly. The final concentrations of furfural and glucose are 50mM and 30mM respectively, and then add the concentration of 30mg (wet cell weight) / mL (buffer solution) to the embodiment 2 The prepared immobilized Pichia mongolica SC1103 cells were reacted at 35° C. and 200 r / min. The reaction was monitored by liquid chromatography ( image 3 ). After 8 hours, the yield of furfuryl alcohol was 90%, and the selectivity was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com