Converter dephosphorizing and steelmaking method

A converter and slag technology, applied in the manufacture of converters, etc., can solve the problems of serious phosphorus return in molten steel, terminal phosphorus control, and difficult control of slag volume, and achieve the effect of saving smelting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the nozzle parameters of the dephosphorization oxygen lance and the five-hole oxygen lance adopted by a certain steel plant are shown in Table 2.

[0042] Table 2 Nozzle parameters of dephosphorization oxygen lance and 5-hole oxygen lance

[0043]

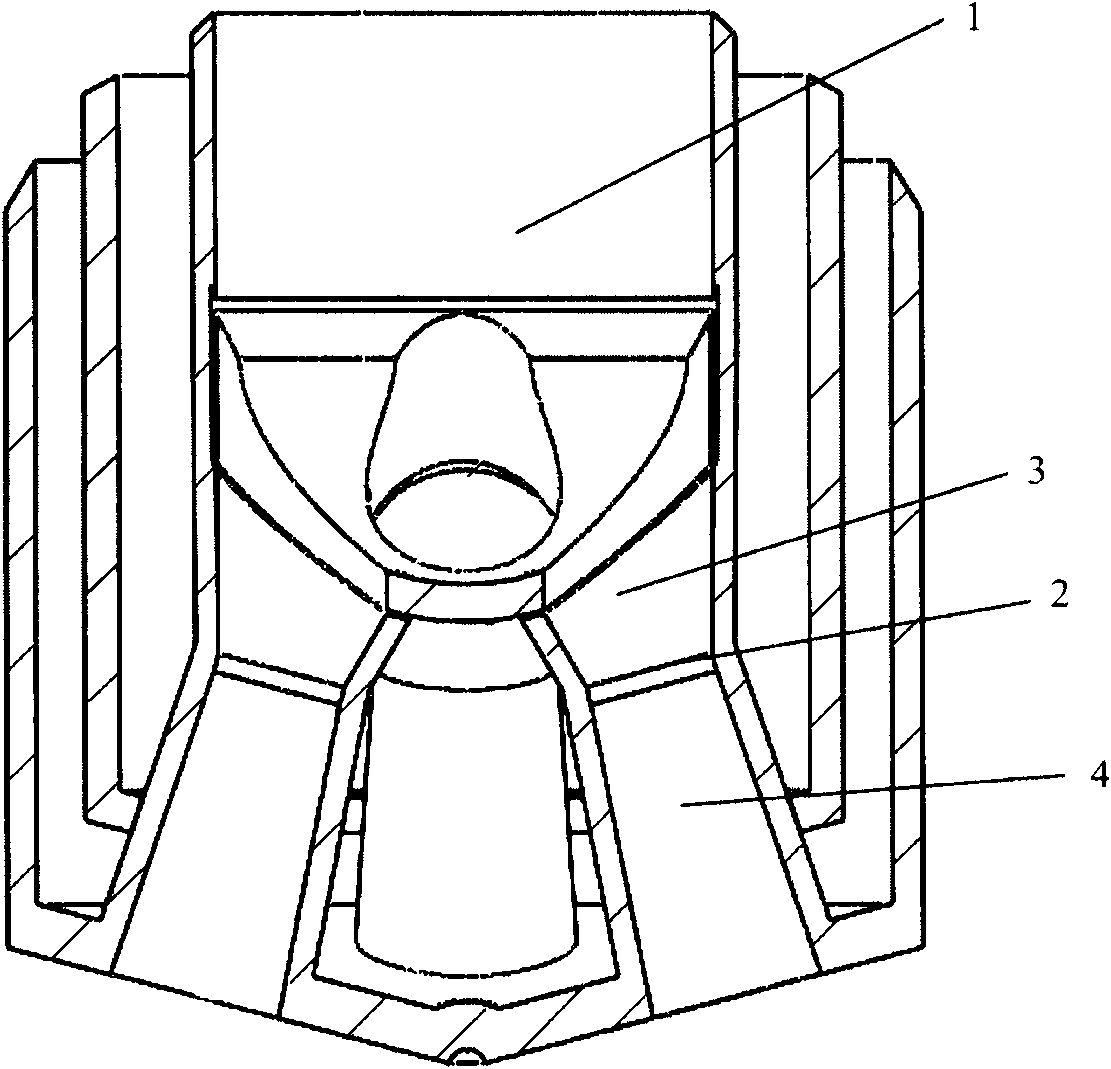

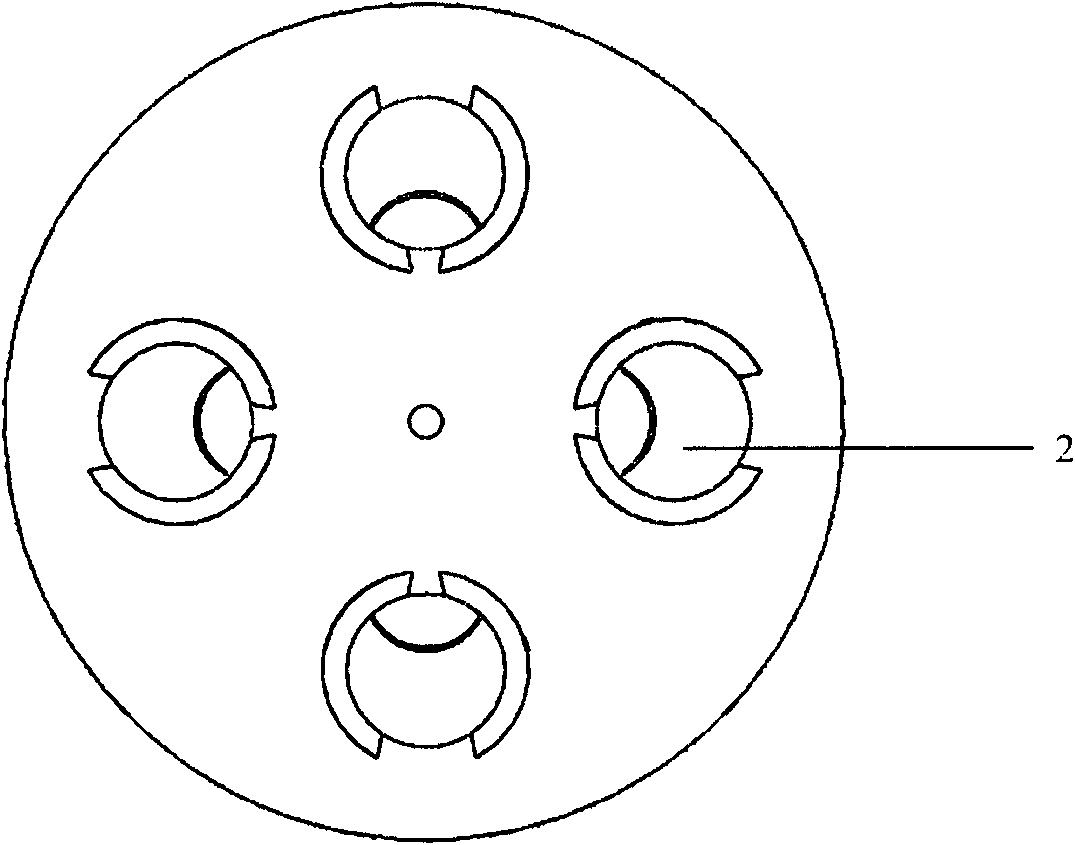

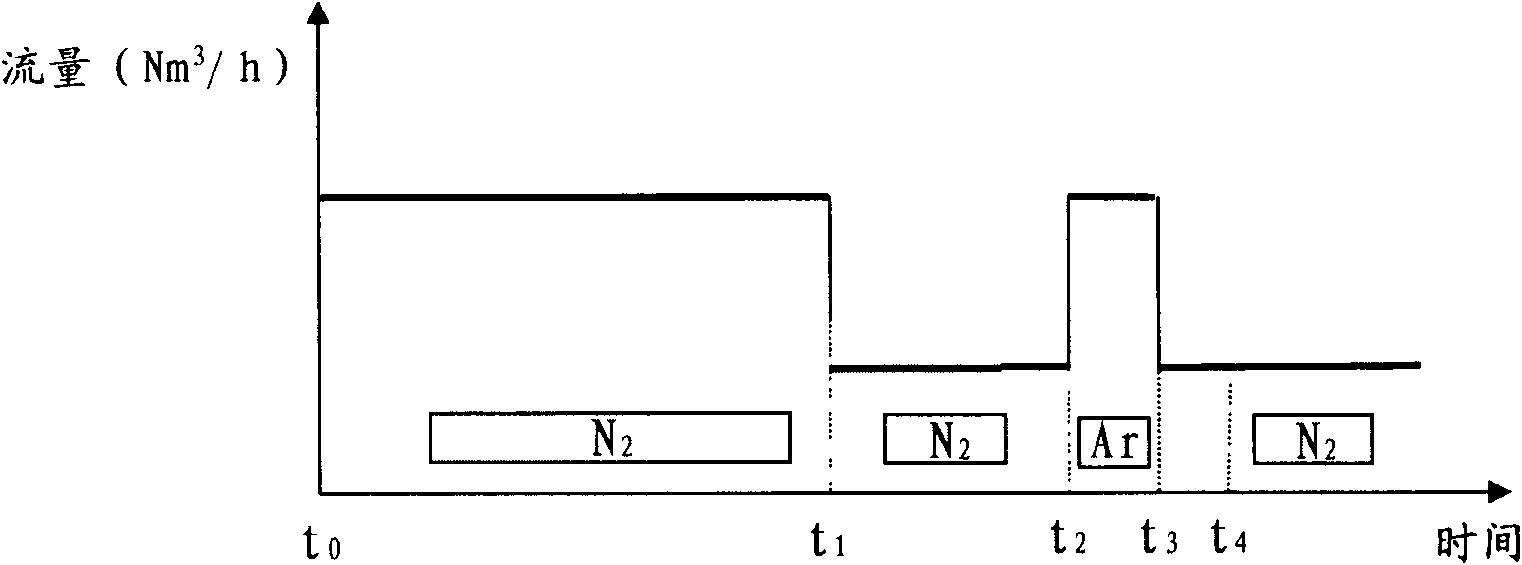

[0044] The 120-ton converter in a steel plant adopts such as figure 1 and figure 2 When the shown dephosphorization oxygen lance is smelted, the oxygen flow rate is 16000Nm 3 / h, the working pressure is 0.7MPa, the oxygen supply intensity is 1.91m3 / (t steel min), and the first batch of slagging materials is added: active lime 10kg / t 半钢 ;The amount of high magnesium lime added is 10kg / t 半钢 ; The amount of compound slagging agent added is 22kg / t 半钢 ; In the later stage of dephosphorization, the amount of sludge ball added is 5.1kg / t 半钢 . The above-mentioned slag-making materials are gradually added in the first 4.5 minutes, and the slag is poured after 7 minutes of dephosphorization oxygen lance b...

Embodiment 2

[0049] In this embodiment, the nozzle parameters of the dephosphorization oxygen lance and the five-hole oxygen lance adopted by a certain steel plant are shown in Table 4.

[0050] Table 4 Nozzle parameters of dephosphorization oxygen lance and 5-hole oxygen lance

[0051]

[0052] When a 120-ton converter in a steel plant is smelted with a dephosphorization oxygen lance, the oxygen flow rate is 15000Nm 3 / h, the working pressure is 0.7MPa, the oxygen supply intensity is 1.96m 3 / t 钢 , the amount of the first batch of slagging material added: active lime 20kg / t 半钢 ;The amount of high magnesium lime added is 20kg / t 半钢 ; The amount of compound slagging agent added is 10kg / t 半钢 ; In the later stage of dephosphorization, the amount of composite slag added is 10kg / t 半钢 In the dephosphorization period, the auxiliary materials are gradually added in the first 4 minutes, and the dephosphorization oxygen lance is blown for 8 minutes and then the slag is poured out. After repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com