All-perovskite multiferroic magnetoelectric compound film and preparation method thereof

A magnetoelectric composite and ferromagnetic thin film technology, applied in the direction of magnetic layer, ion implantation plating, coating, etc., can solve problems such as difficult to obtain contact interface, poor compatibility, and affecting device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this example, using the pulsed laser deposition method, the LaAlO 3 (001) substrate, the substrate temperature is 600-750°C, the working pressure is 10Pa, the laser energy is 300mJ / pulse, the pulse frequency is 10Hz, the working gas is high-purity (5N) oxygen, and the target-base distance is 50mm. La 2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 Thin film, used to deposit La 2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 The target material of the thin film is La 2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 Ceramic target; in the above La2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 After the thin film is deposited, it is annealed at a substrate temperature of 850° C. for 1 hour under the protection of an oxygen atmosphere. BaTiO 3 Film thickness is 400nm, La 2 / 3 Sr 1 / 3 MnO 3 The film thickness is 400-800nm.

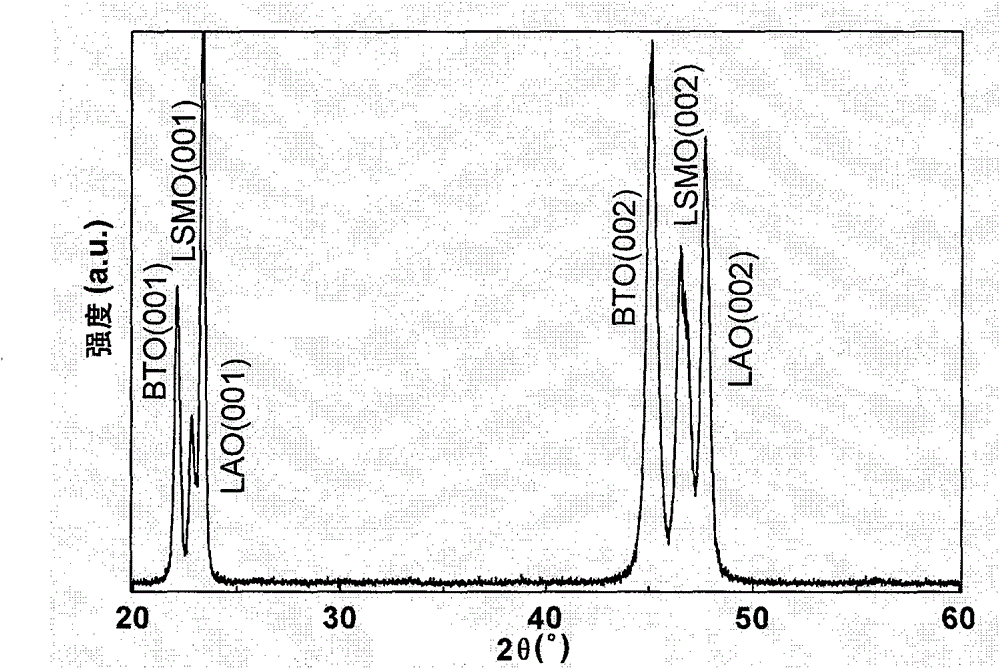

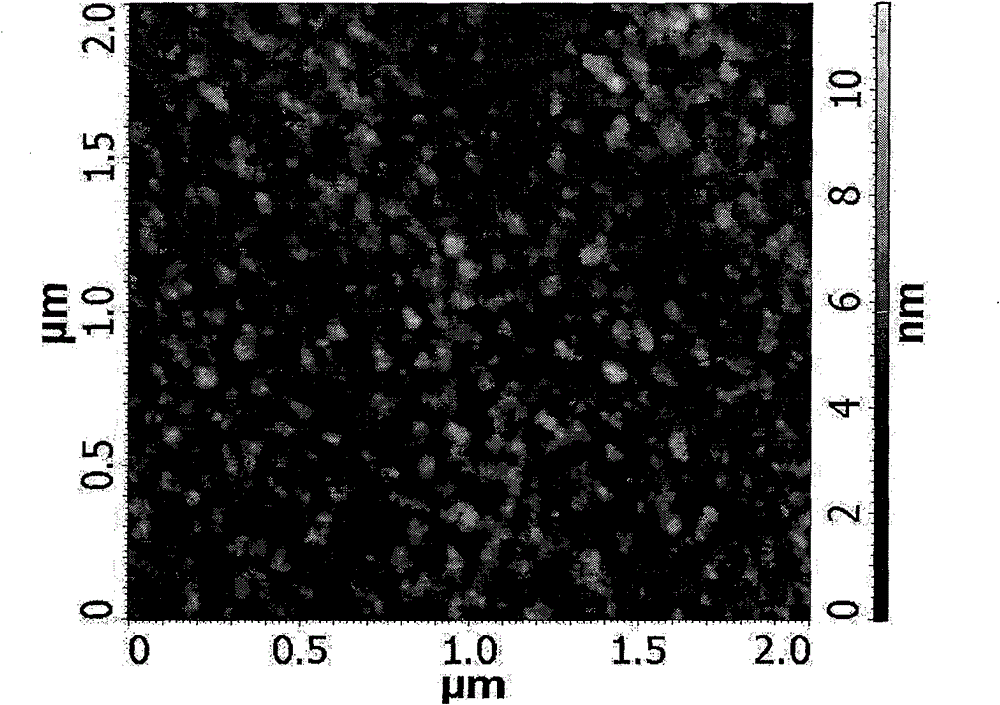

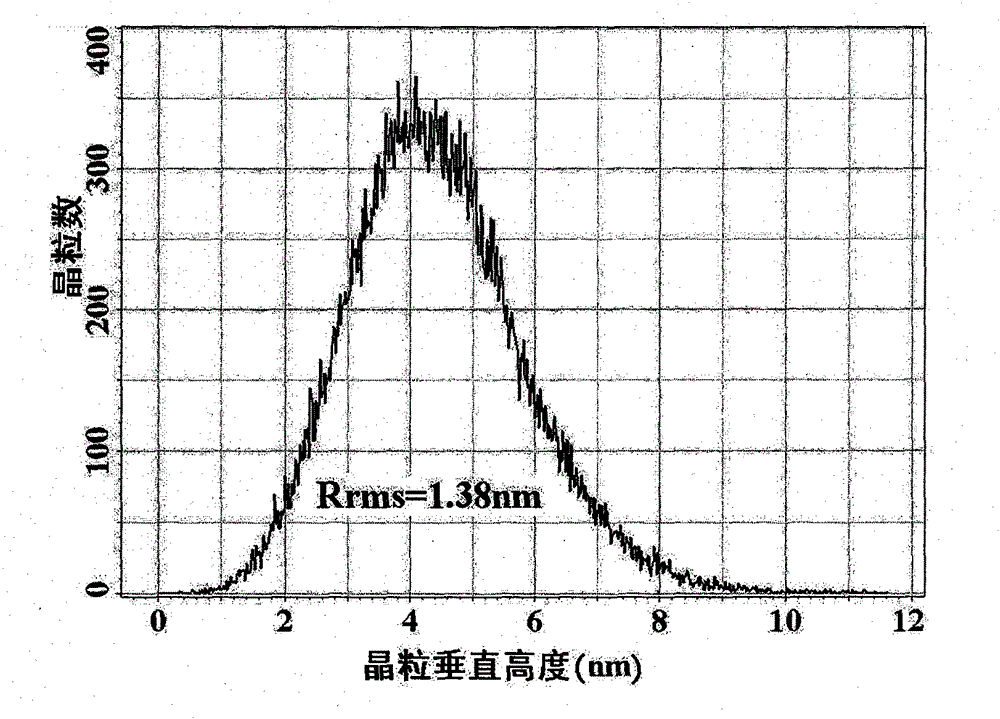

[0024] The XRD of the resulting composite film is as follows figure 1 As shown, due to the use of the La 2 / 3 Sr 1 / 3 MnO 3 Lattice-matched LaAlO 3 (001) substrate, and the introduction of oxygen annealing ...

Embodiment 2

[0027] This embodiment is the implementation of the best preparation process, and the specific preparation conditions are: substrate LaAlO 3 (001) The temperature is 700°C, the working pressure is 10Pa, the laser energy is 300mJ / pulse, the pulse frequency is 10Hz, the working gas is 10Pa high-purity oxygen, the distance between the target and the base is 50mm, and La 2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 Thin film, used to deposit La 2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 The target material of the thin film is La 2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 Ceramic target, BaTiO 3 Film thickness is 400nm, La 2 / 3 Sr 1 / 3 MnO 3 The film thickness is 600 nm. In the above La 2 / 3 Sr 1 / 3 MnO 3 and BaTiO 3 After the thin film is deposited, it is annealed at a substrate temperature of 850° C. for 1 hour under the protection of an oxygen atmosphere.

[0028] The magnitude of the magnetoelectric effect of the composite film is related to the thickness ratio of the ferroelectric and ferromagnetic layers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com