Planar magnetic-control sputtering target improving utilization efficiency

A technology of magnetron sputtering and high utilization rate, applied in the field of planar sputtering targets, can solve the problems of non-reusable materials, waste of target materials, high cost of film manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

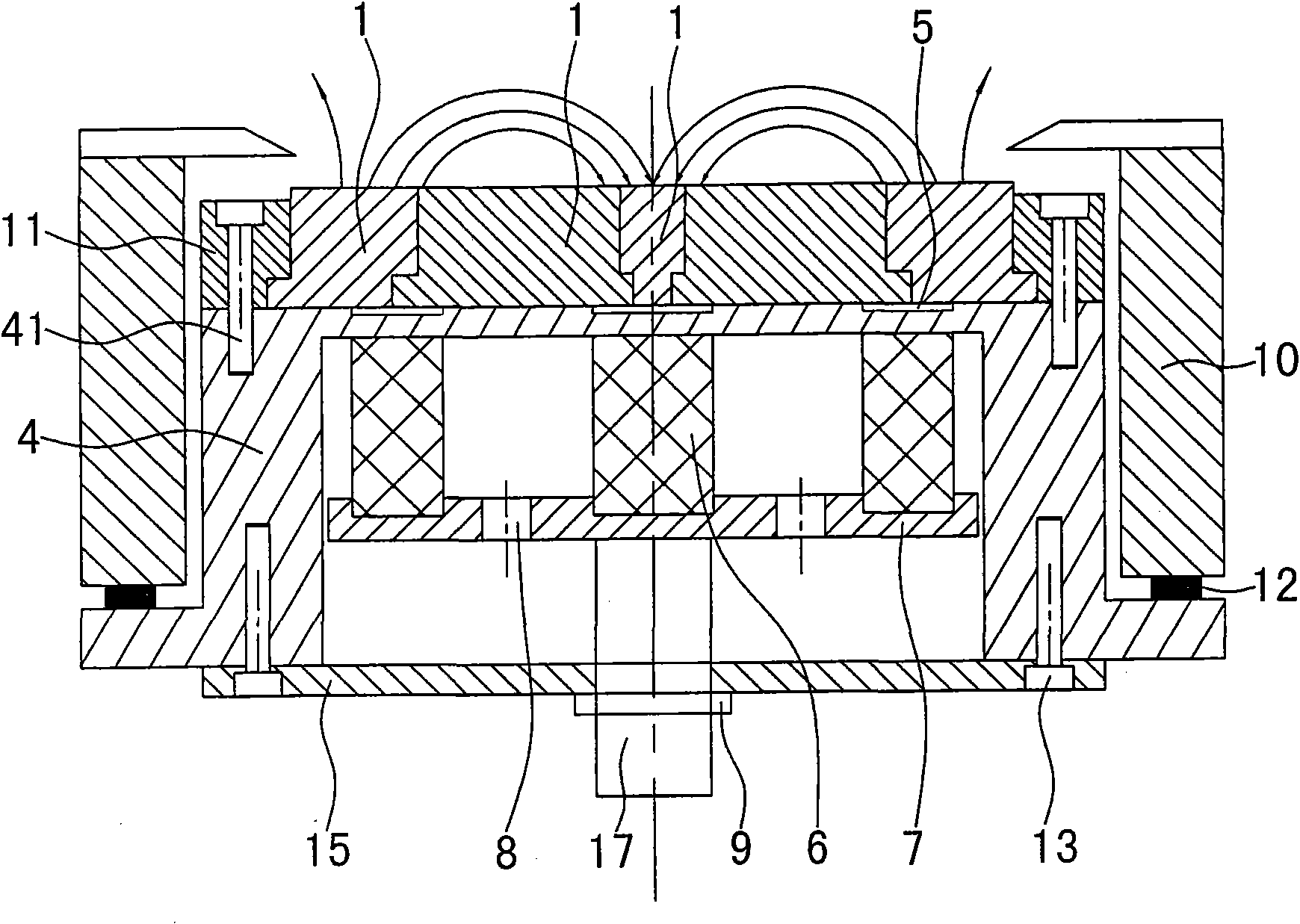

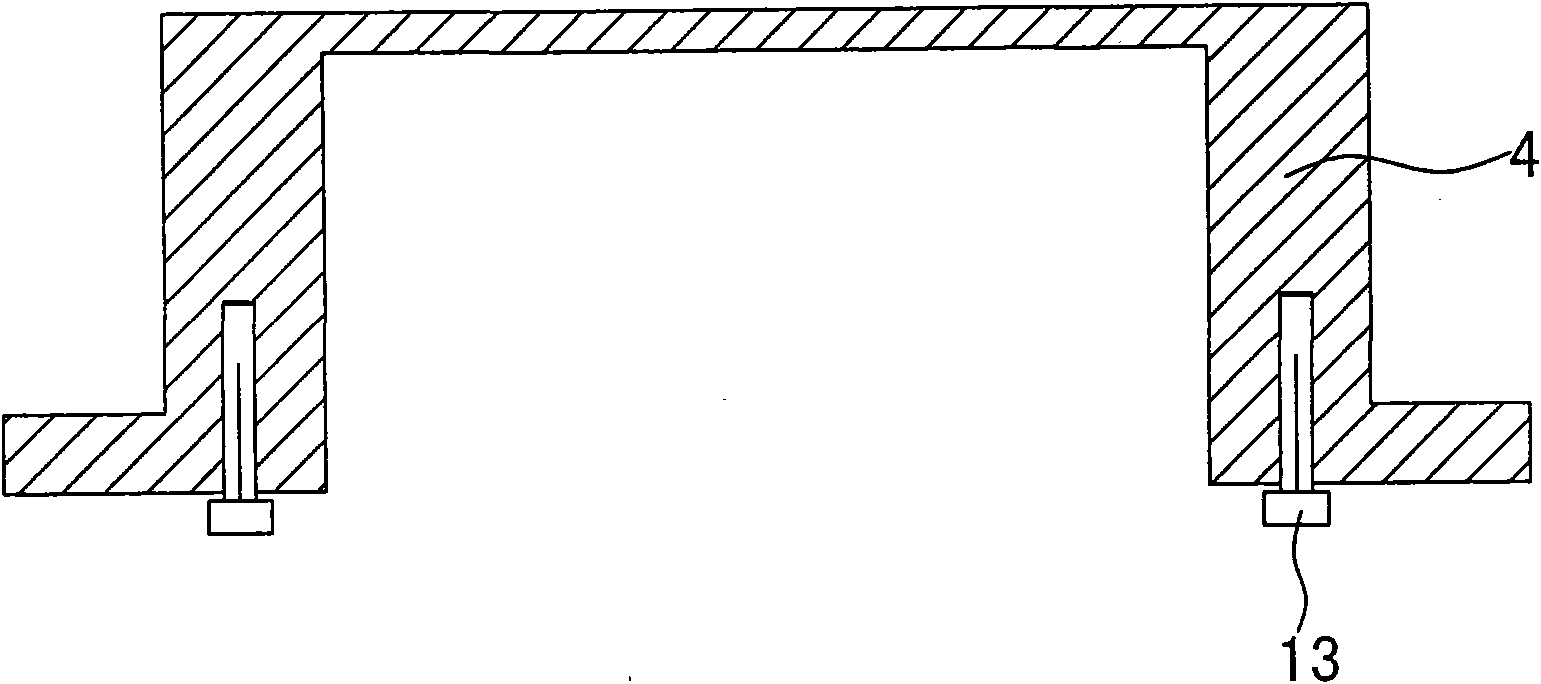

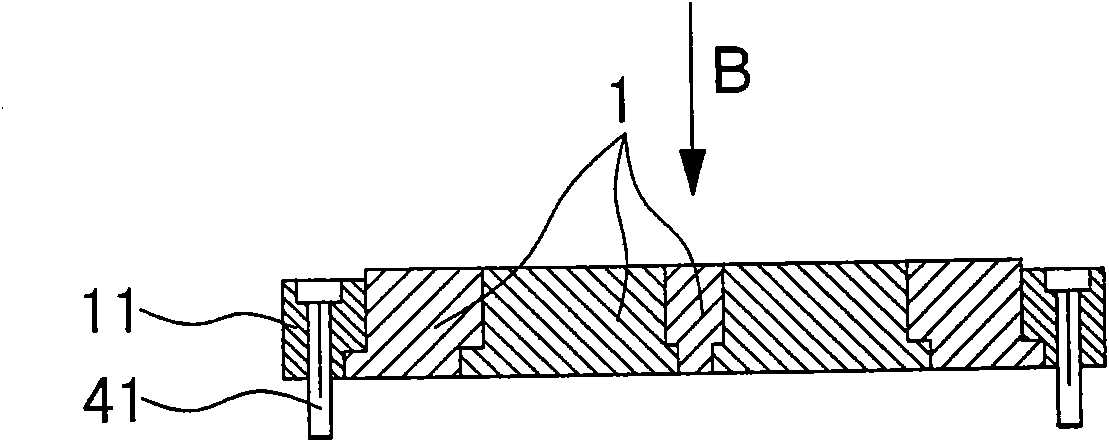

[0016] The invention relates to a planar magnetron sputtering target with improved utilization rate, such as Figure 1-Figure 9 As shown, it is characterized in that it includes a target magnetron jacket 4, the bottom surface of the target magnetron jacket 4 is connected to a cover plate 15, there is cooling water between the cover plate 15 and the target magnetron jacket 4, and the target magnetron A magnetron 7 is placed inside the tube jacket 4, and a water hole 8 is formed in the magnetron 7. A permanent magnet 6 is installed on the magnetron 7, and a target bar 1 is installed on the magnetron jacket 4 of the target material, and there is a target material on the outside of the target bar. Bar fixing block 11, the target material bars 1 are arranged in parallel and alternately, the target material bars overlap each other, the surface of the target material bar 1 is a flat surface, and there are The target shield 10 , the magnetic poles of the permanent magnet 6 connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com