Non-destructive detection method for pile bottom karst

A non-destructive detection and karst technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of high cost, inaccurate judgment of karst scale, long construction period, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

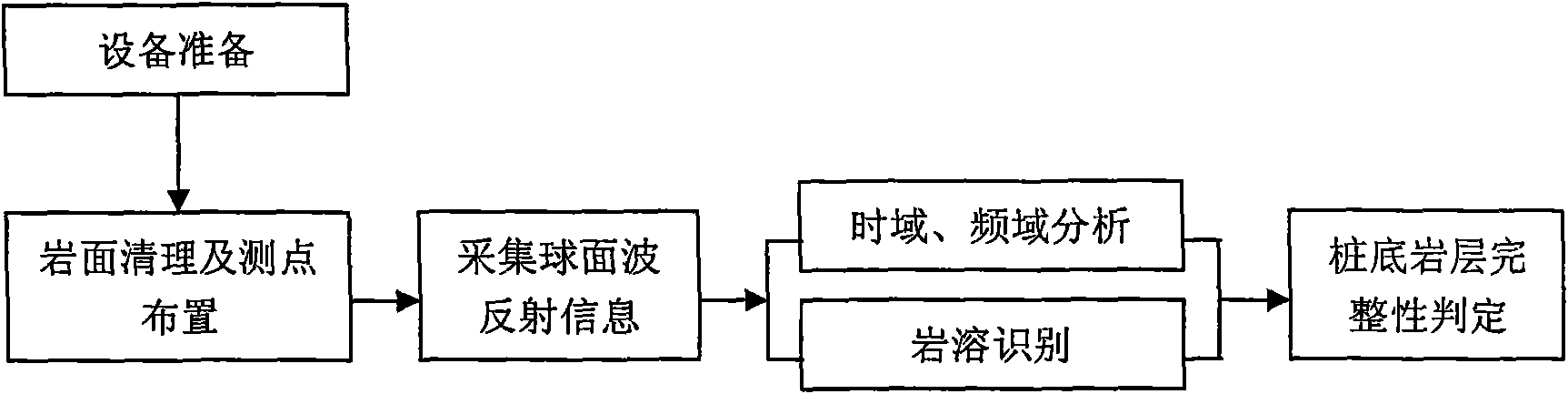

Method used

Image

Examples

Embodiment

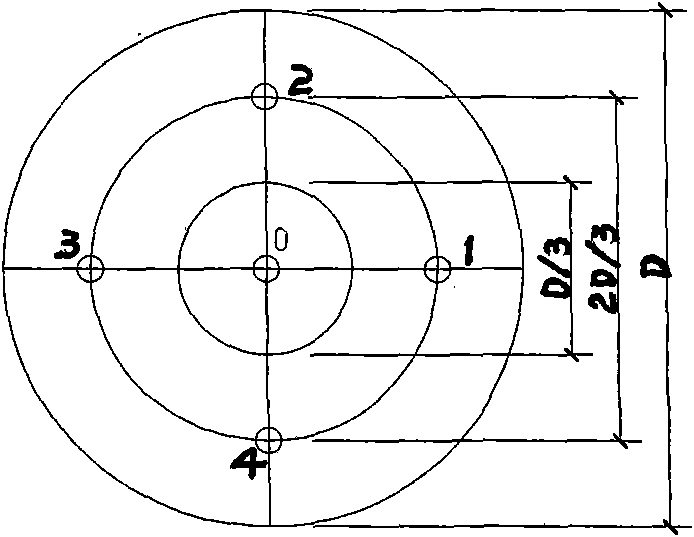

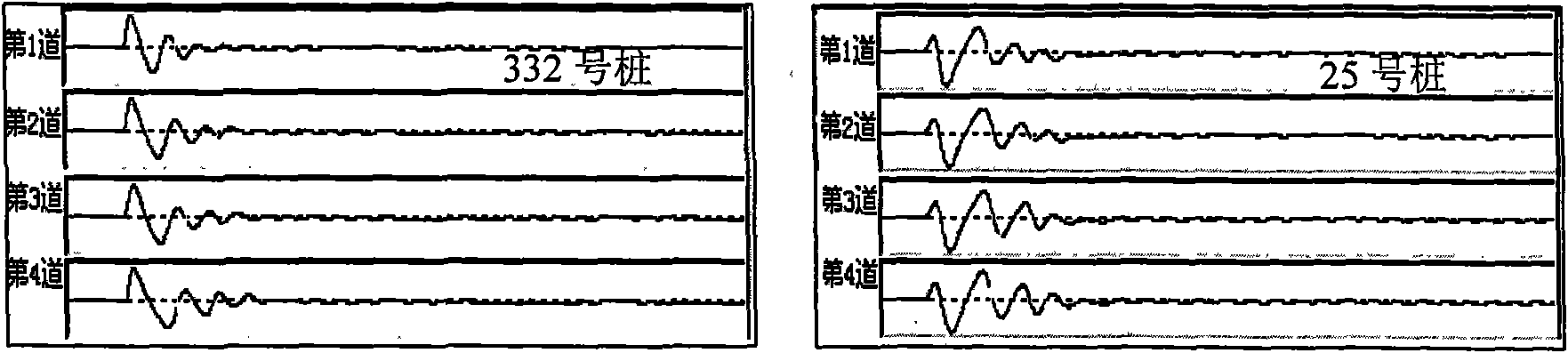

[0074] A power plant project adopts artificial excavated pile foundations. According to the design requirements, the bottom of the pile needs to enter 1m of complete limestone, and no karst cavities can exist within 5d (d=1.2m) below the bottom of the pile. To this end, the pile bottom karst non-destructive detection technology is used to detect the development degree of pile bottom karst. The on-site detection time of each pile is about 5 minutes. During continuous detection, 40 piles can be completed every day.

[0075] (1) Equipment preparation (equipment input)

[0076] ① The project invested in a handheld vibration testing instrument FDP204 (produced by Wuhan Yan Saturn Technology Development Co., Ltd.), equipped with a velocity type seismic sensor, the coupling agent is viscous grease for lubrication, and the vibrating hammer is a multi-purpose nylon hammer.

[0077] The instrument comes with a set of analysis software, which can perform conventional time domain and freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com