Method and device for sampling produced fluid of oil reservoir for microbial flooding

A sampling device and microbial flooding technology, applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problem of unreachable high temperature, high pressure, closed sampling, unreachable high pressure and closed sampling, redox potential The problem of high value, etc., achieves the effect of simple structure, reduced damage, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

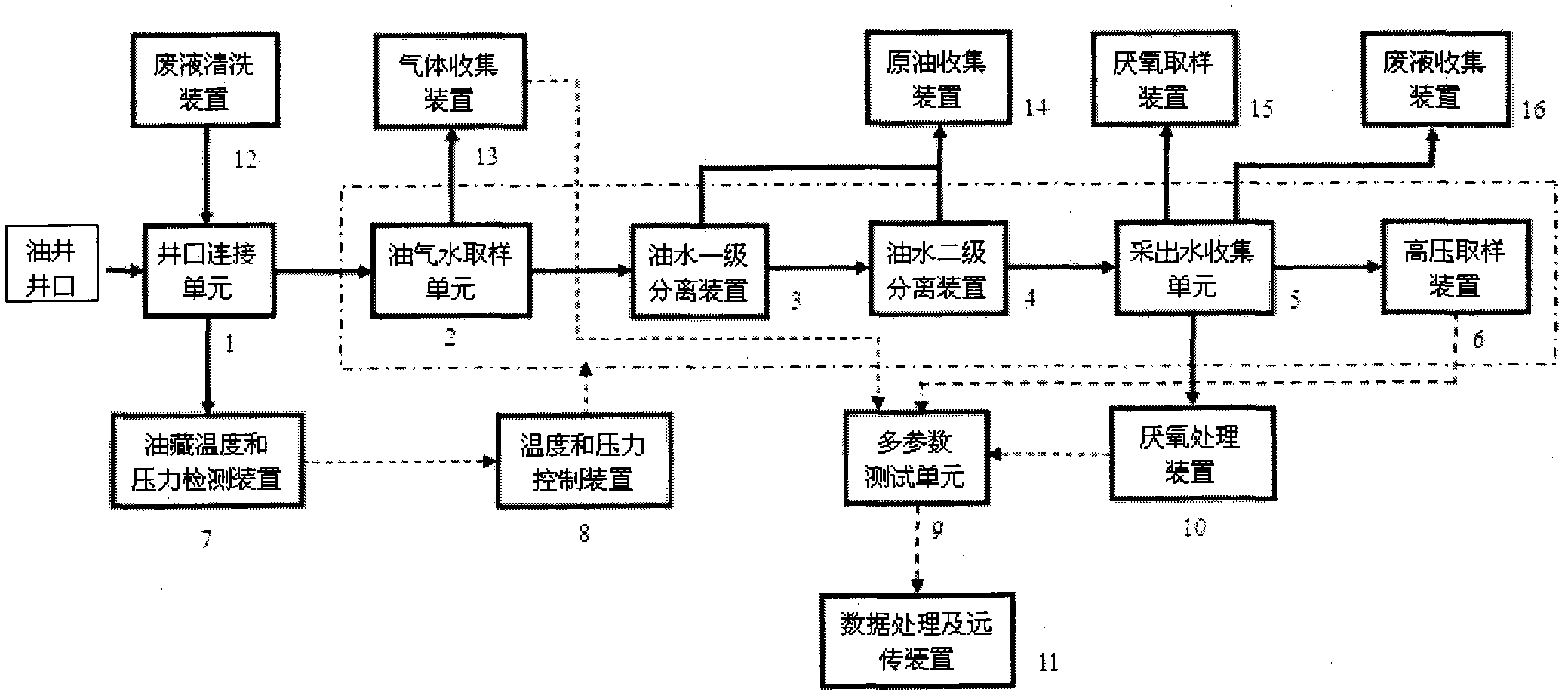

[0043] combined with figure 1 , taking a certain microbial flooding oil reservoir---the Ng3 internal test in the first district as an example, the present invention is further elaborated:

[0044] A method for high-temperature, high-pressure and anaerobic sampling of oil production fluid in microbial flooding reservoirs, comprising the following steps:

[0045] (1) Reservoir temperature and pressure testing and control

[0046] First, the pressure of the Ng3 reservoir in the first zone detected by the pressure detection device is 10.0 MPa, and the temperature of the Ng3 reservoir in the first zone detected by the temperature detection device is 69°C, and then fed back to the temperature and pressure control device respectively, and the pressure control device controls the sampling device. The pressure is constant at 10MPa, and the temperature control device controls the temperature of the sampling device to be constant at 69°C.

[0047] (2) Anaerobic treatment of sampling devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com