Semiconductor device and lead frame thereof

A semiconductor and lead frame technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as difficult to improve withstand voltage, and achieve high withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

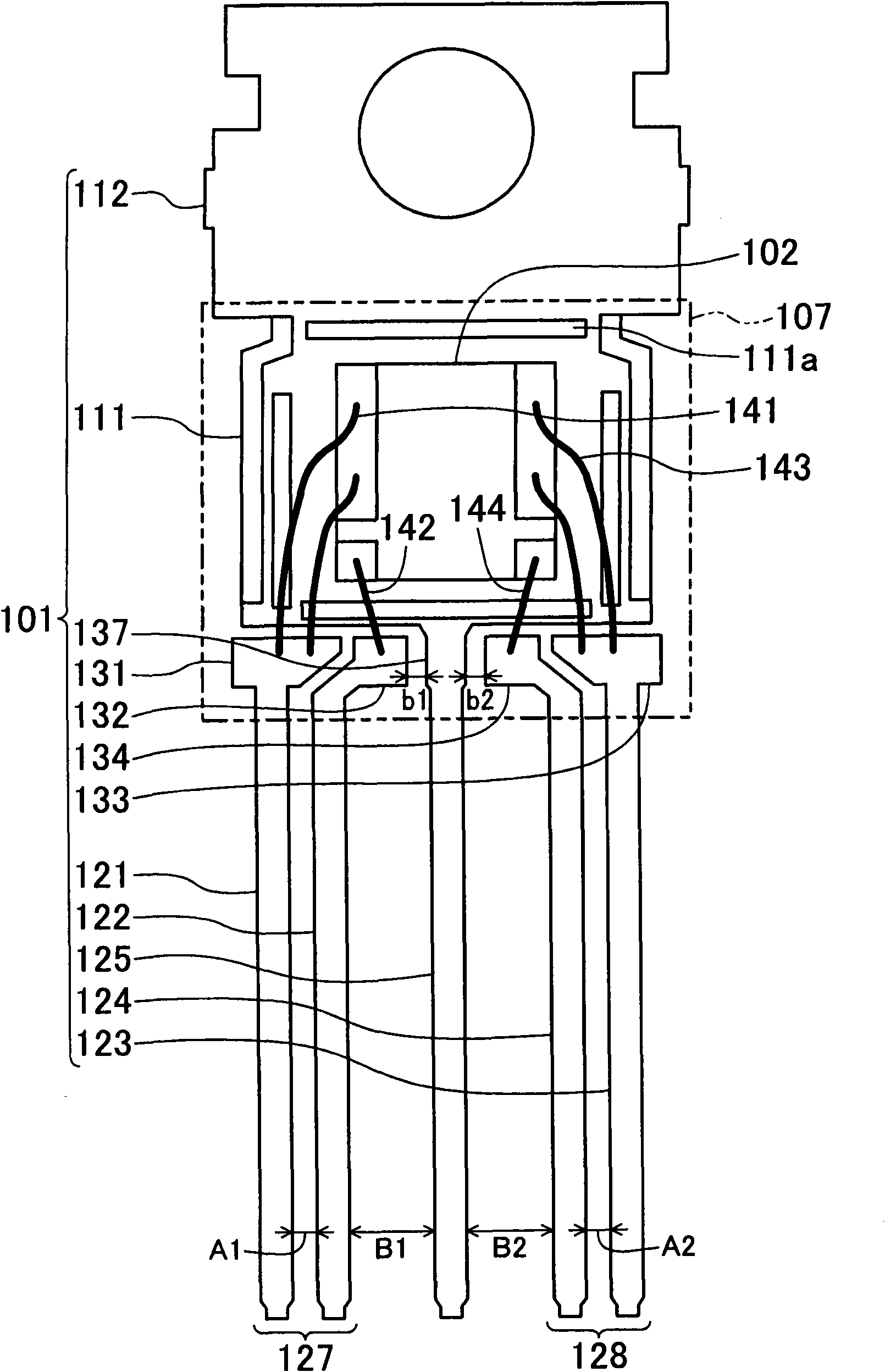

[0086] figure 1 A plan view structure of a semiconductor device according to an embodiment is shown. Such as figure 1 As shown in FIG. 2 , a semiconductor element 102 is mounted on a lead frame 101 and sealed by an insulating sealing portion 107 made of resin. and, in figure 1 Only the position of the insulating seal 107 is shown in .

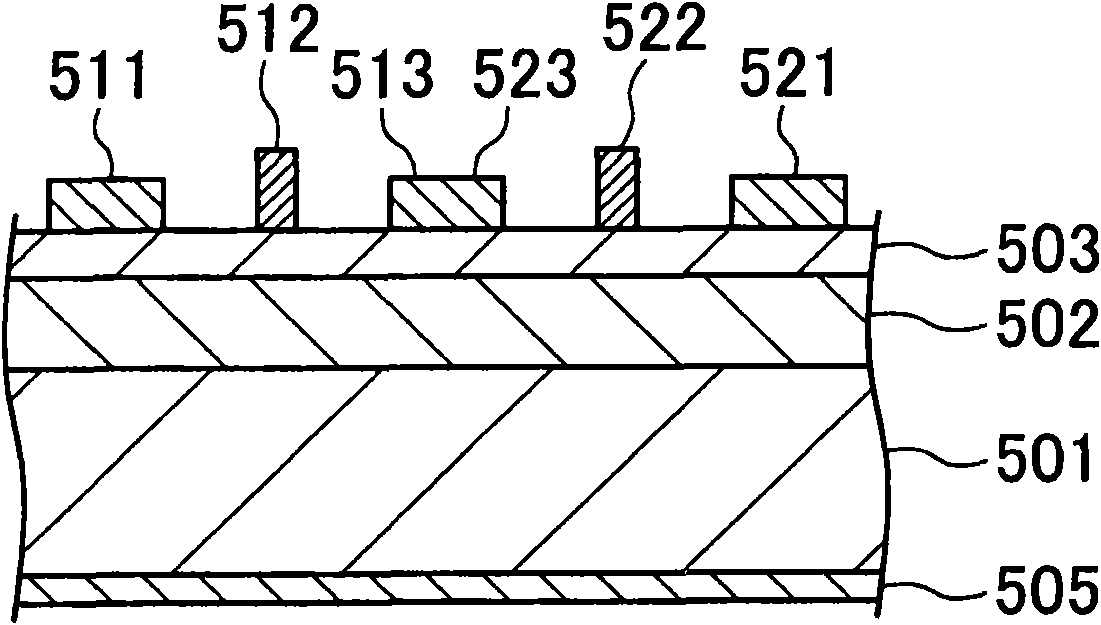

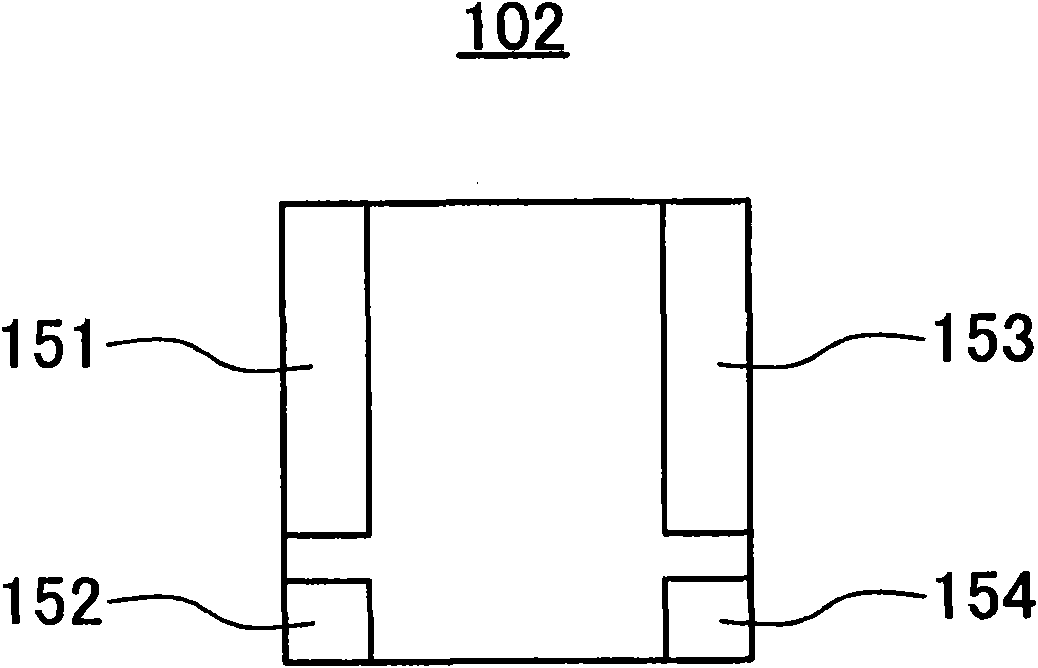

[0087] The semiconductor element 102 is, for example, a switching element for electric power or the like. If a specific example is given, it is as follows figure 2 Two field effect transistors (FETs) made of nitride semiconductors are integrally formed on a substrate as shown. A first nitride semiconductor layer 502 serving as a channel layer and a second nitride semiconductor layer 503 serving as an electron supply layer are sequentially formed over a substrate 501 . The first nitride semiconductor layer 502 may be, for example, gallium nitride (GaN), and the second nitride semiconductor layer 503 may be, for example, aluminum galliu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com