High-tension transformer

A high-voltage transformer and iron core technology, applied in the field of high-voltage transformers, can solve the problems of reducing distributed capacitance, differential high-voltage output characteristics, etc., and achieve the effects of increasing withstand voltage, minimizing harmonics, and reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

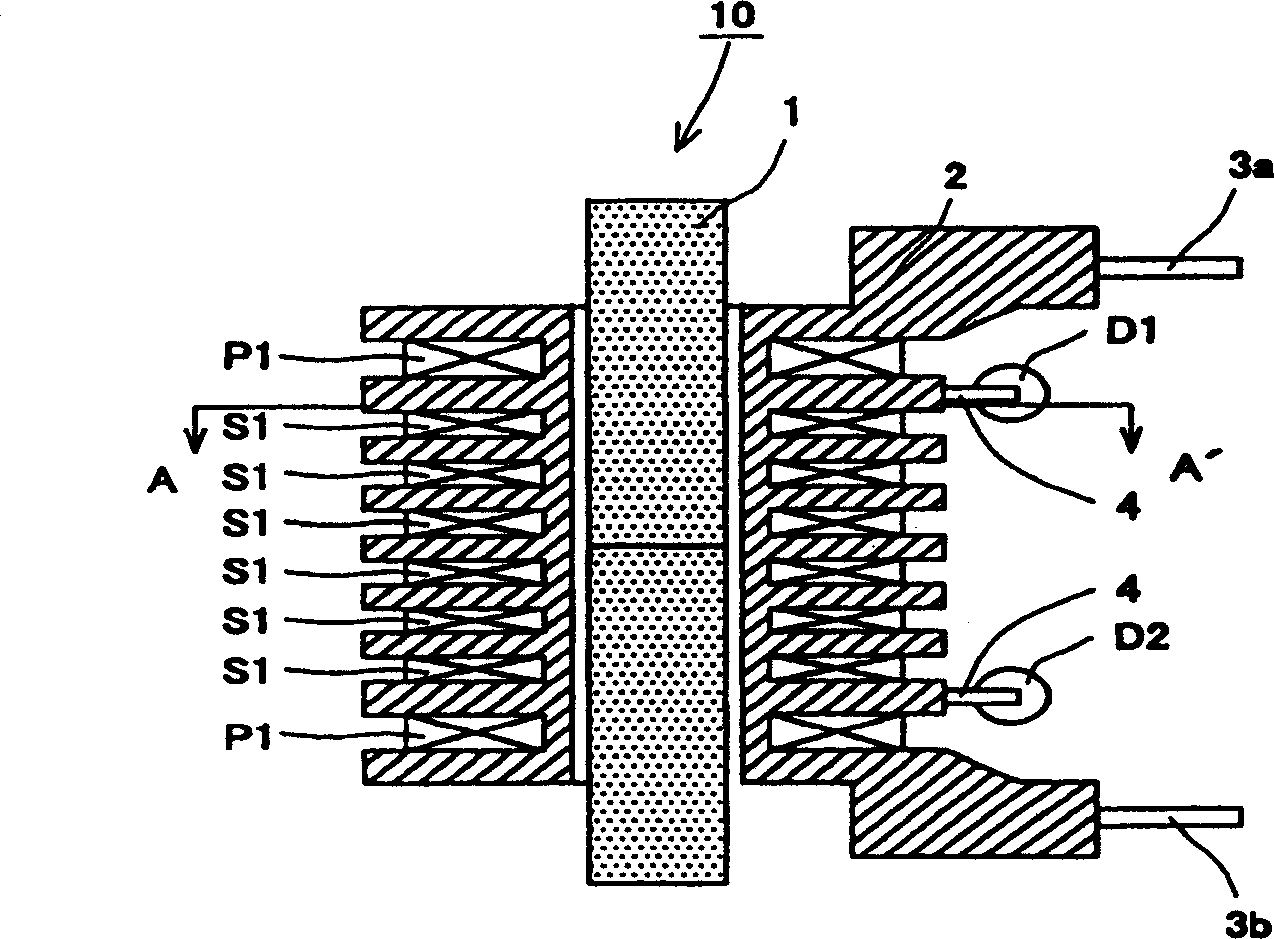

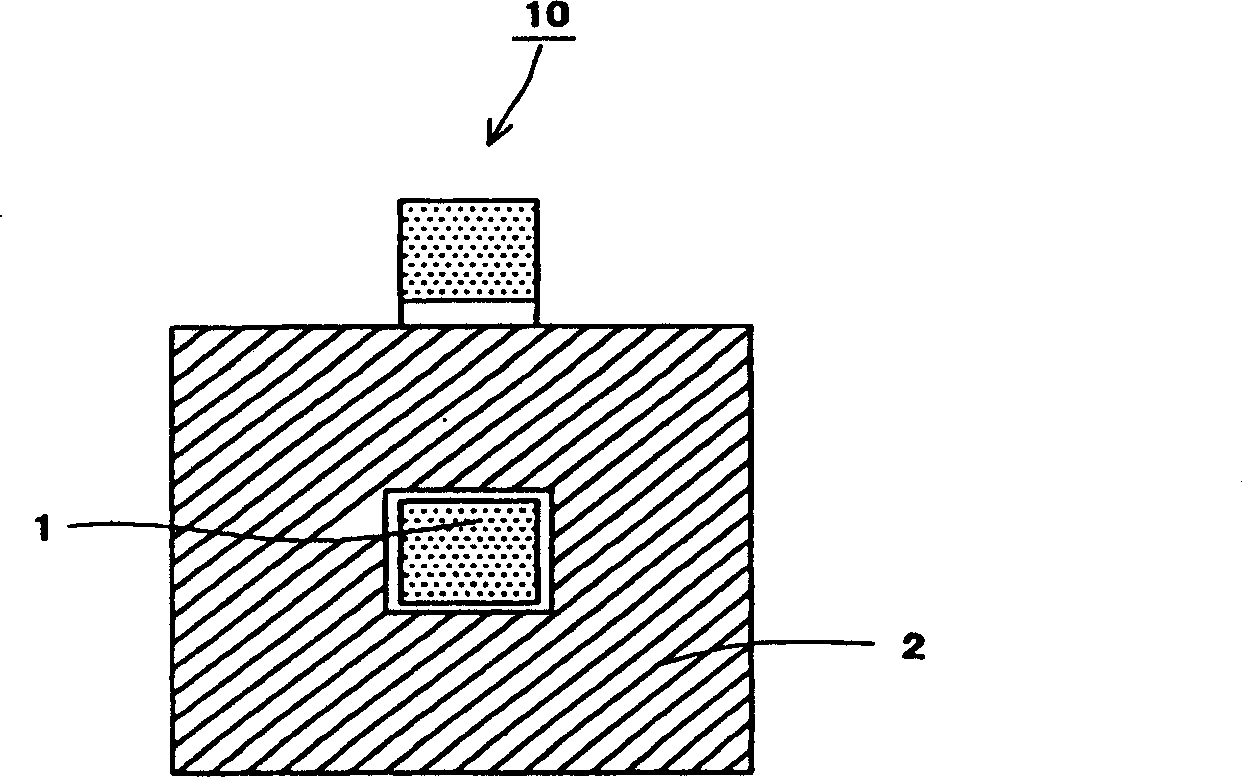

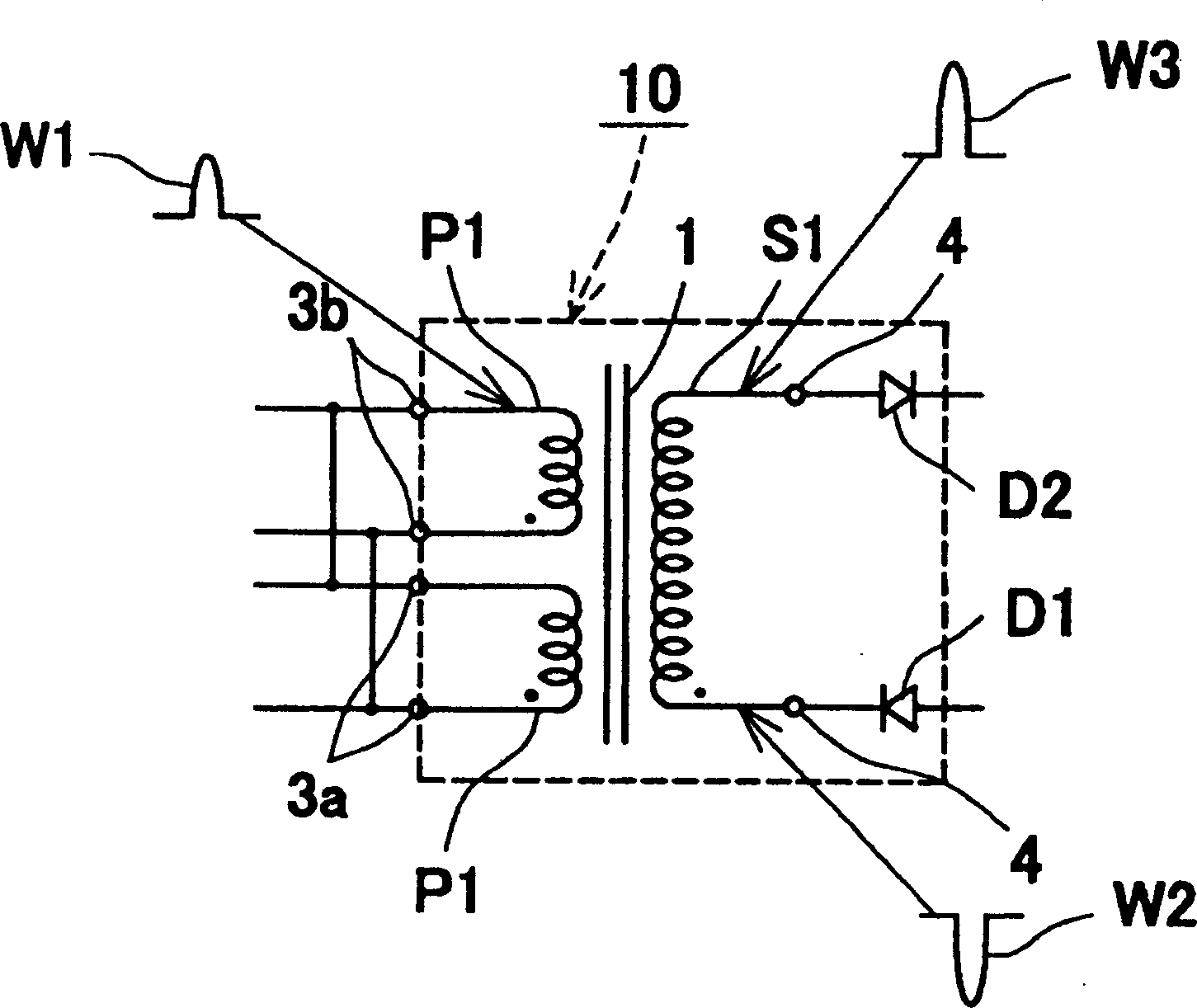

[0019] Now, will refer to Figure 1A , 1B and figure 2 , the first preferred embodiment of the present invention will be described. Figure 1A is the vertical cross-sectional view of the high-voltage transformer; Figure 1B is along Figure 1A The horizontal section obtained by the line A-A' in ; and figure 2 is a circuit diagram showing pulses generated by a high voltage transformer. refer to Figure 1A , 1B and figure 2 , the high voltage transformer 10 includes a bobbin 2 supporting an iron core 1 at the center thereof. For example, the core 1 is a horseshoe ferrite having a substantially square cross-section of approximately 4mm by 4mm. For example, the bobbin 2 is made of polybutylene terephthalate (PBT). The bobbin 2 has a hole for receiving the core 1 . The holes have a substantially square horizontal cross-section and a vertical cross-section that is the same throughout its length. For example, the bobbin 2 has nine flanges arranged along the central axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com